Square Steel Billet Q235,Q255,Q275,Q345,3SP,5SP,20MnSi Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Square Steel Billet Q235,Q255,Q275,Q345,3SP,5SP,20MnSi Made in China

Specification

Steel billet(ingot) by cogging or breakdown of semi-finished products, is the raw material of all kinds of steel mill. Billet section of square, round, flat, rectangular and abnormity of several kinds of, mainly related to the shape of rolled products.

CNBM Q235,Q275,Q345,3SP,5SP,20MnSi Billets Steel in Hot Sale

Hot Rolled Steel Billets/ Mild Steel Bar/ Billet Steel Square Steel Billet

Specification (see below)

Standard: GB/JIS/ASTM

Size: 50*50mm-180*180mm

Length: 3-12mtrs or Customised

Steel material: Q235,Q255,Q275,Q345,3SP,5SP,20MnSi

Technique: Hot rolled

FOB Unit Ton Price $250-350 and Usually I will quote you CFR price.

MOQ: Usually 1000-10000MT/size

Shipment:By Container,Bulk Vessel

Packaging Details: bundles with steel strips or as customers's requirements

Delivery time: Usually within 30 days after the deposit/LC

Inspection:Third party inspection before loading.

Technical data

Feature Steel Billet

Rectangular billet continuous casting billet and mainly general carbon steel, low carbon low silicon cold-rolled material, high quality carbon structural steel, high strength low alloy steel, special steel, etc.

The billet is mainly divided into two kinds from the shape:

Slab: cross section width and height of the ratio of the larger, mainly used for rolling plate.

Billet: equal cross section width and height, or a huge difference, mainly used for rolling steel, wire rod. ,

Steel billets have distinct characteristics as compared with already furnished steel bars and products. Billets have a specific grain structure, which enables the metal to be processed more intricately. Steel billets are also known for their malleability and ductility, especially when exposed to varying temperatures during shaping and molding.

Packaging & Shipping

1. Packaging:

1) Small size: in bundles

2)Big size: in bulk

3)in plastic packing or as per customer requirement

2. Delivery time:

1) Normal size: within 7days send from warehouse directly

2) Special size: with 25-30days customer made for you

3. Trade terms:FOB/CFR/CIF

4. Shippment:

1) length:≤5.8m loaded in 20FT Container with 25-27tons

2) length:≤11.8m loaded in 40FT Container with 25-27tons

3) lengnth:≥12m shipped by bulk vessel, FILO terms

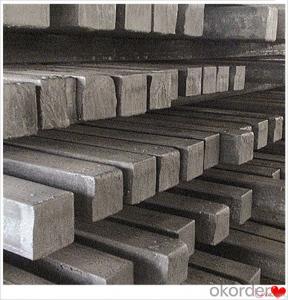

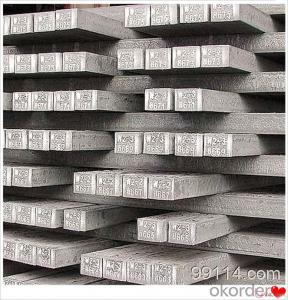

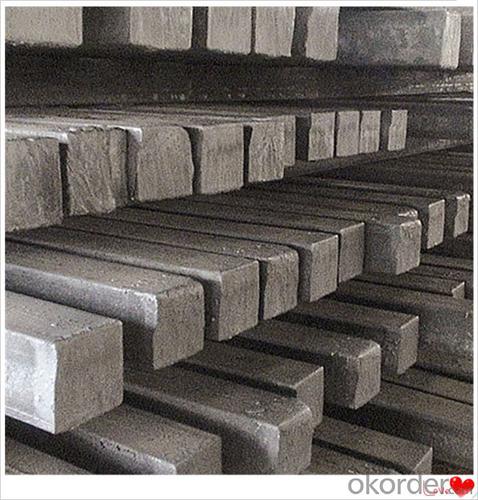

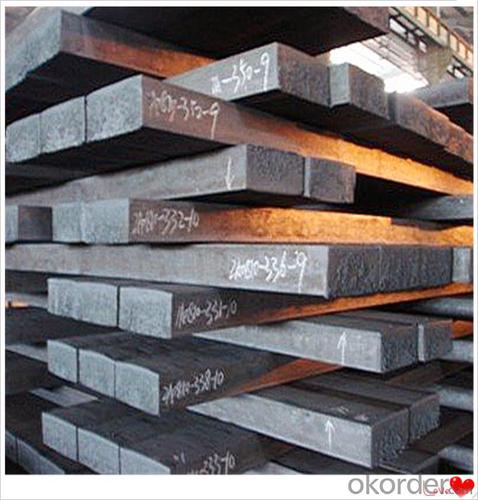

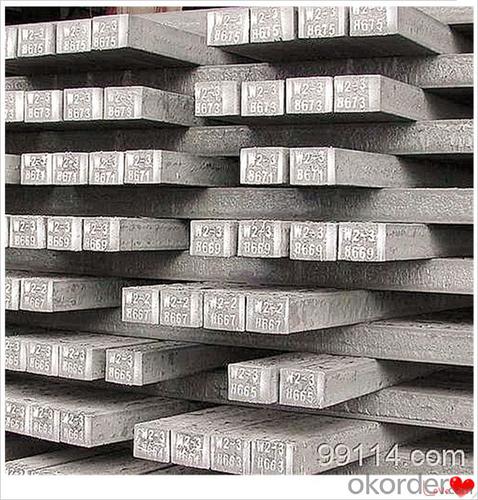

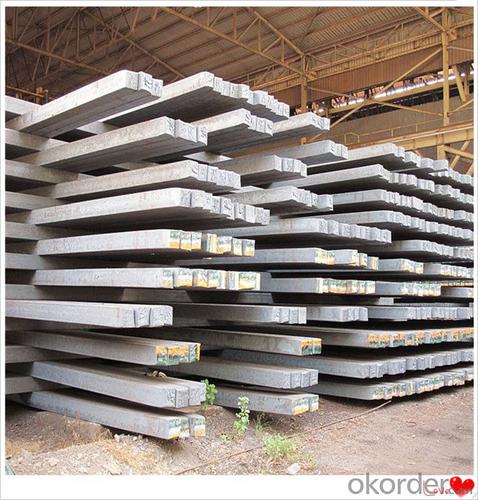

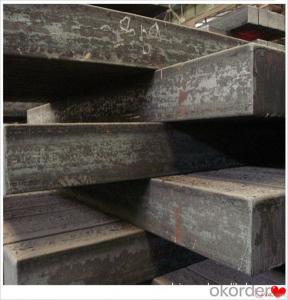

Steel Billet Images

Processing

Usage-Billet Steel

Used for the plant, the bridge,shipment building high-rise building construction,lifting and transportation machinery, equipment manufracturing base building the support foundation pile manufacturing.

Billets, or ingots (as they sometimes referred to), are not of practical use until they have been formed into more functional shapes and sizes. While they have already been put in the furnace, they still require a series of shaping and molding procedures such as hot and cold working, milling and cutting before they are sold in hardware stores, or used for different applications. The unformed billets, however, can be used in striking currency such as coins and as reserves, similar to gold bars.

FAQ-Billet Steel

We have organized several common questions for our clients,may help you sincerely:

1) How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3) How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

4)Do you have your own QC department?

Yes, we have, our QC department will inspect the goods during the process of mass production and after completion of production.

hot sale!!! Cast Steel Grades/ mild steel bar/ billet steel

(1): High quality steel with reasonable price.

(2): Wide excellent experiences with after-sale service.

(3): Every process will be checked by responsible QC which insures every product's quality.

(4): Professional packing teams which keep every packing safely.

(5): Trial order can be done in one week.

(6): Samples can be provided as your requirements.

- Q: Can steel billets be used for making musical instruments?

- Yes, steel billets can be used for making musical instruments, particularly for percussion instruments like steel drums and xylophones.

- Q: Are steel billets affected by extreme temperatures?

- Steel billets can be affected by extreme temperatures. High temperatures cause them to expand and deform due to the thermal expansion property of steel. Conversely, extremely low temperatures can make steel billets contract and become more brittle as the cold temperature reduces their ductility, making them more susceptible to fracture. Hence, it is essential to take into account the impact of extreme temperatures on steel billets during their design, handling, and storage to avoid any undesired deformation or failure.

- Q: What are the different surface treatments for improved fatigue resistance in steel billets?

- To enhance the fatigue resistance of steel billets, several surface treatments can be utilized. These treatments aim to improve the steel's fatigue strength by reducing crack formation and propagation, increasing resistance to cyclic loading conditions. Some common surface treatments include: 1. Shot peening: This technique involves bombarding the steel billets with small metallic or ceramic particles at high velocities. By inducing compressive residual stresses on the surface, crack initiation and propagation are prevented, thus improving fatigue resistance. 2. Nitriding: Through this heat treatment process, nitrogen is diffused into the surface layer of the steel billets. This creates a hard nitride layer, increasing hardness, wear resistance, and fatigue strength. 3. Carburizing: Carbon is diffused into the surface layer of the steel billets at high temperatures, increasing carbon content and forming a hardened layer. This enhances fatigue resistance and wear properties. 4. Shot peen forming: Controlled shot peening induces plastic deformation in the steel billets. This treatment improves fatigue resistance, as well as shape and dimensional stability. 5. Surface coatings: Protective coatings can be applied to the surface of steel billets to enhance fatigue resistance. Techniques such as electroplating, thermal spraying, and chemical vapor deposition can deposit wear-resistant and fatigue-enhancing coatings. It is important to consider specific application requirements, steel type, and desired fatigue improvement level when choosing a surface treatment. Thorough consideration and testing should be conducted to determine the most suitable technique for a particular application.

- Q: Billet production process

- Billets are produced by three process methods:First, through the steelmaking system of continuous casting equipment, from the direct pouring of molten steel billet;Two is the steel ingot produced by the steelmaking system or the continuous casting billet processed by the rolling equipment of the steel rolling system, and the three is the semi-finished product processed by the forging equipment of the steel ingot produced by the steelmaking system.

- Q: What are the common surface defects in steel billets during cooling?

- Common surface defects in steel billets during cooling include cracks, surface scaling or oxidation, and surface decarburization.

- Q: Can steel billets be used in the production of sculptures and artwork?

- Yes, steel billets can be used in the production of sculptures and artwork. Steel is a versatile and malleable material that allows artists to create unique and intricate designs. The use of steel billets in sculptures and artwork offers durability, strength, and the potential for large-scale installations. Artists can shape, weld, and manipulate steel billets to create a wide range of sculptures, from abstract forms to figurative representations. The industrial aesthetic of steel can also add a contemporary and bold element to the artwork. Additionally, steel can be finished with various techniques such as painting, patina, or polishing, allowing artists to further enhance their creative vision. Overall, steel billets present an exciting opportunity for artists to explore and push the boundaries of their artistic expression.

- Q: What are the different types of surface defects found in steel billets?

- There are several types of surface defects that can be found in steel billets. These defects can occur during the manufacturing process or due to external factors. Some of the common surface defects found in steel billets include: 1. Scale: Scale is a type of oxide layer that forms on the surface of the billet during the heating and cooling processes. It appears as a thin layer of rust-like material and can affect the quality and appearance of the steel. 2. Cracks: Cracks can occur due to improper cooling or excessive stress during the manufacturing process. These cracks can be either longitudinal or transverse and can weaken the structural integrity of the billet. 3. Pits: Pits are small depressions or cavities that can be found on the surface of the billet. They can occur due to the presence of impurities or as a result of corrosion. 4. Seam: A seam is a linear defect that can be found along the surface of the billet. It is caused by the improper joining of two sections of the billet during the manufacturing process. 5. Lamination: Lamination defects occur when there are layers or flakes of material that separate from the surface of the billet. This can be caused by improper rolling or an inadequate bonding between layers. 6. Inclusions: Inclusions are non-metallic particles or impurities that are trapped within the steel billet during the manufacturing process. These inclusions can affect the mechanical properties of the steel and reduce its overall quality. 7. Decarburization: Decarburization is a surface defect where the carbon content of the steel is reduced, leading to a softer and weaker surface layer. This can occur due to improper heating or cooling processes. It is important to detect and address these surface defects in steel billets to ensure the quality and performance of the final steel products. Various inspection methods and quality control measures are employed during the manufacturing process to minimize the occurrence of these defects.

- Q: How do steel billets contribute to the renewable energy sector?

- Steel billets play a crucial role in the renewable energy sector by supporting the manufacturing of various renewable energy technologies. One of the main ways steel billets contribute to this sector is by providing the necessary raw material for the construction of wind turbines. Wind turbines require strong and durable structures to withstand the harsh environmental conditions, and steel billets serve as the primary material for manufacturing their towers and foundations. Moreover, steel billets are used in the production of solar panels. These panels are made up of photovoltaic cells that convert sunlight into electricity. Steel billets are used to create the frames and mounting structures that provide support and stability to the solar panels, ensuring their proper functioning and longevity. Additionally, steel billets are used in the manufacturing of hydroelectric power equipment. Hydroelectric power is generated by converting the kinetic energy of flowing or falling water into electricity. The turbines used in hydroelectric power plants are often made from steel billets due to their high strength and resistance to corrosion. The billets are used to create the turbine blades, shafts, and other components that help generate electricity from water. Furthermore, steel billets are essential for the manufacturing of energy storage systems, such as batteries. Renewable energy sources like wind and solar are intermittent, meaning they are not constantly available. Energy storage systems help store excess energy generated during peak times and release it when the demand is high. Steel billets are used in the construction of battery casings and structural components, ensuring the safety and durability of these storage systems. In conclusion, steel billets contribute significantly to the renewable energy sector by providing the essential raw material for the construction of wind turbines, solar panels, hydroelectric power equipment, and energy storage systems. Their strength, durability, and resistance to corrosion make them a vital component in the manufacturing of various renewable energy technologies, ultimately helping to accelerate the transition towards a more sustainable and greener future.

- Q: How do steel billets contribute to the overall energy efficiency of a structure?

- There are several ways in which steel billets enhance the energy efficiency of a structure. To begin with, steel is an incredibly durable material that can withstand the test of time. Consequently, structures constructed using steel billets have a longer lifespan, which reduces the frequency of maintenance and repairs. As a result, energy consumption and costs decrease over time. Furthermore, steel boasts excellent heat and electricity conductivity. This characteristic facilitates the efficient distribution of thermal energy throughout the structure, thereby reducing the need for additional heating or cooling systems. Steel structures are proficient at regulating internal temperature and minimizing energy loss, resulting in improved energy efficiency. Moreover, steel manufacturing processes have become increasingly energy-efficient in recent years. Modern techniques involve recycling scrap steel, utilizing electric arc furnaces, and implementing advanced technologies to minimize energy consumption during the production of steel billets. This emphasis on energy efficiency during the manufacturing stage translates into reduced environmental impact and energy savings throughout the lifespan of the structure. Additionally, steel structures can be designed to optimize natural lighting and ventilation. This reduces reliance on artificial lighting and mechanical ventilation systems. Incorporating features like large windows, skylights, and well-designed air circulation systems enables steel structures to minimize the need for energy-consuming lighting fixtures and HVAC systems, further enhancing energy efficiency. In conclusion, steel billets contribute to the overall energy efficiency of a structure through their durability, thermal conductivity, and energy-efficient manufacturing processes. By opting for steel as a building material, structures can benefit from reduced maintenance requirements, efficient temperature regulation, and minimized energy consumption. This leads to long-term energy savings and a more sustainable built environment.

- Q: Reasons and treatment methods of billet stripping in continuous casting

- even two cold regions can be uniformly cooled, due to uneven thickness of shell, caused by the inconsistent temperature, the shell shrinkage is still uneven, and also there will be the development of. Therefore, the selection of unqualified mold is the main reason causing the removal. Secondly, the cooling effect of the two cooling zone can not be ignored.

Send your message to us

Square Steel Billet Q235,Q255,Q275,Q345,3SP,5SP,20MnSi Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords