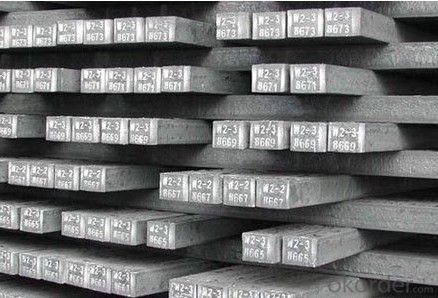

20MnSi Prime Steel Billet 150x150mm 120*120mm

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering 20MnSi Prime Steel Billet 150x150mm 120*120mm at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to African, South American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

20MnSi Prime Steel Billet 150x150mm 120*120mm are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's 20MnSi Prime Steel Billet 150x150mm 120*120mm are durable, strong, and wide variety of sizes.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: 20MnSi

Certificates: ISO, SGS, BV

size:60*60/90*90/100*100/120*120/150*150

Length: 6m/12m,

Packaging: Export packing, nude packing, bundled

Standard | C(%) | Mn(%) | S(%) | P(%) | Si(%) |

20MnSi | 0.17-0.25 | 1.2-1.6 | ≤ 0.050 | ≤ 0.050 | 0.40-0.80 |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will arrange production. The normal sizes with the normal grade can be produced within one month. The specific shipping date is dependent upon international and government factors, the delivery to international main port about 45-60days.

Images:

- Q: Can steel billets be used for marine applications?

- Yes, steel billets can be used for marine applications. Steel billets are commonly used in the construction of ships, offshore structures, and marine equipment due to their high strength, durability, and corrosion resistance properties. They provide the necessary strength to withstand the harsh marine environment and can be shaped and welded to meet specific design requirements.

- Q: What are the main uses of steel billets in the automotive industry?

- Steel billets are primarily used in the automotive industry for manufacturing various components such as engine parts, transmission parts, chassis, suspension systems, and body structures. These billets serve as a raw material for forging and casting processes, allowing for the production of durable and high-strength automotive components that ensure safety, performance, and longevity of vehicles.

- Q: How are steel billets used in the production of seamless pipes?

- Seamless pipes, which are manufactured without welding or seams, require steel billets as a fundamental component in their production process. Steel billets are rectangular-shaped solid pieces of steel that serve as the raw material for seamless pipe manufacturing. To produce seamless pipes, the initial step is melting steel in a furnace to obtain molten metal. This molten steel is then poured into molds to shape steel billets. These billets are then heated to a specific temperature and pierced using a piercing mill. This mill exerts both axial and radial forces, pushing a pointed mandrel through the center of the billet, resulting in a hollow tube or shell. Following the piercing process, the hollow tube is further elongated and reduced in diameter by a series of rolling mills. These mills apply a combination of rotational and compressive forces to shape the billet into the desired seamless pipe size. The seamless pipe undergoes continuous stretching and rolling until it reaches the desired length and diameter. The utilization of steel billets in the production of seamless pipes holds significant importance for several reasons. Firstly, the billets are crafted from high-quality steel, guaranteeing the strength and durability of the final product. Secondly, the uniformity and consistency of the billets allow for precise shaping and seamless pipe dimensions. Lastly, the solid structure of the billets enables them to withstand the intense forces and temperatures involved in the pipe manufacturing process. In conclusion, steel billets assume a crucial role in the production of seamless pipes. From being melted and molded into billets to being pierced, elongated, and rolled, these billets undergo a series of processes that transform them into high-quality seamless pipes. The use of steel billets ensures the integrity and reliability of seamless pipes, making them suitable for various industrial applications.

- Q: What is the purpose of using steel billets in the manufacturing industry?

- In the manufacturing industry, steel billets are primarily used as a raw material for further processing and shaping into different steel products. These billets are semi-finished metal products that are cast in specific shapes and sizes, typically in square or rectangular cross-sections. The utilization of steel billets serves as a consistent and standardized starting point for the production of a wide array of steel products, including bars, rods, wire, tubes, pipes, and structural components. By employing steel billets, manufacturers can ensure the uniformity of material properties and dimensions in their end products, which is vital for maintaining quality and meeting industry standards. In addition, steel billets offer numerous advantages in terms of strength, durability, and versatility. Steel is renowned for its exceptional strength-to-weight ratio, making it an optimal choice for applications that necessitate high structural integrity and load-bearing capacity. The use of steel billets enables manufacturers to fabricate components that can withstand heavy loads, extreme temperatures, and harsh environmental conditions. Furthermore, steel billets can be easily shaped and processed through various techniques such as rolling, forging, extrusion, and machining. This flexibility empowers manufacturers to create a diverse range of steel products with various shapes, sizes, and properties, catering to the diverse needs of different industries. Overall, the purpose of utilizing steel billets in the manufacturing industry is to provide a dependable and versatile raw material for producing top-quality steel products that serve various applications in sectors such as construction, automotive, aerospace, machinery, infrastructure, and many others.

- Q: How are steel billets used in the production of reinforcing bars?

- Steel billets are an essential component in the production of reinforcing bars. These billets, which are semi-finished steel products, serve as the raw material for the manufacturing process. To produce reinforcing bars, the steel billets are heated to a specific temperature in a furnace. This heating process helps to improve the malleability of the steel, making it easier to shape and manipulate. Once the billets have reached the desired temperature, they are then passed through a series of rolling mills. These mills apply significant pressure to the billets, gradually reducing their size and shaping them into the required dimensions for reinforcing bars. The rolling process also helps to improve the mechanical properties of the steel, enhancing its strength and durability. After the rolling process is complete, the now elongated steel bars are cut into specific lengths according to the desired dimensions and requirements. These lengths are then allowed to cool, which helps to stabilize the steel and prevent any deformations. Finally, the reinforcing bars undergo a surface treatment process, such as hot-dip galvanization or epoxy coating, to provide corrosion resistance and improve their longevity. This treatment further enhances the performance and lifespan of the reinforcing bars, making them suitable for use in construction projects. In summary, steel billets are used as the starting material in the production of reinforcing bars. Through a series of heating, rolling, cutting, and surface treatment processes, the billets are transformed into high-strength steel bars that provide reinforcement to concrete structures.

- Q: How can the quality of steel billets be improved?

- The quality of steel billets can be improved through various methods and techniques. Here are a few approaches that can help enhance the quality of steel billets: 1. Raw Material Selection: The quality of steel billets largely depends on the selection of raw materials. Choosing high-quality raw materials, such as high-grade iron ore and scrap metal, can significantly improve the quality of billets. 2. Melting and Refining: The melting and refining process plays a crucial role in improving steel billet quality. Utilizing advanced melting practices, such as electric arc furnaces (EAF) or induction furnaces, can help achieve a more homogeneous and controlled melting process, reducing impurities and achieving a desired chemical composition. 3. Deoxidation and Degassing: Proper deoxidation and degassing techniques should be employed to remove impurities and gases from the molten metal. This can be achieved by adding suitable deoxidizers and utilizing vacuum degassing processes that effectively remove unwanted gases, thereby enhancing the steel billets' quality. 4. Continuous Casting Process: Implementing a modern continuous casting process can significantly improve the quality of steel billets. Continuous casting ensures a more uniform structure, reduces segregation, and minimizes the formation of defects commonly associated with traditional ingot casting methods. 5. Heat Treatment: Applying suitable heat treatment processes, such as annealing, quenching, and tempering, can further enhance the mechanical properties and overall quality of steel billets. Heat treatment helps refine the microstructure, improving the steel's strength, hardness, and other desired characteristics. 6. Quality Control: Implementing a robust quality control system is crucial in ensuring the production of high-quality steel billets. Regular monitoring and testing should be conducted throughout the production process to identify and rectify any deviations or quality issues promptly. 7. Skillful Workforce: Employing a skilled and knowledgeable workforce is vital for improving the quality of steel billets. Well-trained technicians and operators can effectively implement various quality improvement techniques and address any production challenges that may arise. By incorporating these methods and techniques, steel manufacturers can enhance the quality of steel billets, resulting in improved mechanical properties, superior surface finish, and increased customer satisfaction.

- Q: What is the role of steel billets in the production of wire rods?

- Steel billets play a crucial role in the production of wire rods. Wire rods are long, cylindrical metal rods that are commonly used in various industrial applications, such as construction, automotive, and manufacturing. The production process of wire rods begins with the melting of steel, which is typically done in an electric arc furnace or a basic oxygen furnace. Once the steel reaches the desired temperature and composition, it is poured into molds to form steel billets. Steel billets are semi-finished products that serve as the starting point for the wire rod manufacturing process. They are solid, rectangular or round bars of steel that undergo further processing to transform them into wire rods. The first step in the conversion of steel billets into wire rods is the reheating process. The billets are heated at a high temperature to make them more malleable and easier to work with. This is typically done in a reheat furnace. After reheating, the billets are passed through a series of rolling mills to reduce their size and shape them into wire rods. These rolling mills use a combination of pressure and heat to deform the steel billets and elongate them into long, thin rods. The process of rolling also helps to improve the mechanical properties of the wire rods, such as their strength and flexibility. Once the wire rods are formed, they may undergo additional treatments, such as cooling, surface treatments, and quality inspections, to meet the specific requirements of different applications. They can be further processed into various products, such as wires, cables, reinforcement bars, or other specialized components. In summary, steel billets are essential in the production of wire rods as they are the starting material that undergoes a series of processing steps, including reheating and rolling, to transform them into the desired shape and properties of wire rods.

- Q: How are steel billets used in the manufacturing of automotive components?

- Steel billets are an essential raw material used in the manufacturing of automotive components. These billets are semi-finished products that are shaped into various forms to create the necessary components. Firstly, steel billets are heated to a specific temperature to make them malleable and easier to work with. Once they reach the desired temperature, they are placed into a mold or die and subjected to intense pressure to shape them into the desired form. This process is known as forging. Automotive components such as engine parts, gears, axles, and suspension components require high strength and durability. Steel billets are preferred for these applications due to their excellent mechanical properties, including high tensile strength, toughness, and wear resistance. After the forging process, the shaped billets are further processed through various techniques such as machining, heat treatment, and surface finishing to achieve the final specifications required by automotive manufacturers. These processes ensure that the components meet the necessary performance standards, dimensional accuracy, and surface quality. The use of steel billets in the manufacturing of automotive components offers several advantages. Steel is readily available, cost-effective, and has a high recycling rate, making it an environmentally friendly choice. Additionally, steel's versatility allows for a wide range of component designs and customization options to meet specific automotive requirements. In conclusion, steel billets play a crucial role in the manufacturing of automotive components. Their malleability and excellent mechanical properties make them an ideal raw material for forging processes, enabling the production of high-strength and durable components used in various automotive applications.

- Q: What are the main factors affecting the dimensional stability of steel billets?

- There are several main factors that can affect the dimensional stability of steel billets. 1. Temperature: One of the most significant factors is temperature. Steel billets can undergo thermal expansion or contraction depending on the temperature they are exposed to. Changes in temperature can cause the billets to expand or contract, leading to dimensional changes. It is crucial to control the temperature during the manufacturing process and subsequent cooling stages to minimize these effects. 2. Cooling rate: The rate at which the steel billets cool down after being heated also affects their dimensional stability. Rapid cooling can result in internal stresses within the billet, causing it to warp or distort. On the other hand, slow cooling can lead to uneven cooling and uneven dimensional changes. 3. Composition: The chemical composition of the steel billets plays a significant role in their dimensional stability. Different alloying elements, impurities, and carbon content can influence the material's behavior during heating and cooling. For instance, higher carbon content can increase the likelihood of warping or distortion. 4. Mechanical stresses: Mechanical stresses from handling, transportation, or machining processes can impact the dimensional stability of steel billets. Excessive bending, twisting, or pressure can cause permanent deformation or residual stresses within the billet, affecting its overall dimensional stability. 5. Heat treatment: The heat treatment process can also influence the dimensional stability of steel billets. Different heat treatment methods, such as annealing, quenching, or tempering, can introduce internal stresses or phase transformations that may alter the billet's dimensions. 6. Manufacturing techniques: The processes used during the production of steel billets, such as casting, rolling, or forging, can have an impact on their dimensional stability. Inadequate control or inconsistencies in these manufacturing techniques can lead to variations in the billet's dimensions. It is crucial to consider and control these factors to ensure the dimensional stability of steel billets, as any dimensional changes can affect the subsequent processing steps and the final product's quality.

- Q: What does the billet of the steel plant refer to?

- The steel billet is the continuous casting machine by smelting steel plant casting into the blank, in the middle of products before entering the rolling process, the section size will be decided by rolling steel.

Send your message to us

20MnSi Prime Steel Billet 150x150mm 120*120mm

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords