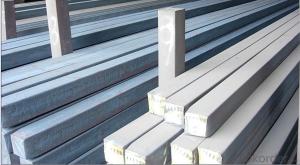

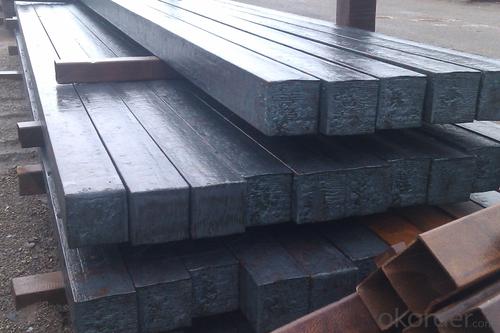

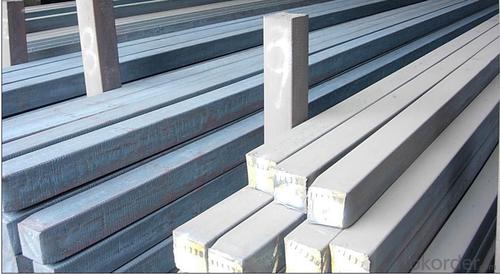

Prime Q275 120mm Square Alloy Steel Billet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Prime Q275 120mm Square Alloy Steel Billet

Description of Prime Q275 120mm Square Alloy Steel Billet

1. Prepainted steel coil is coated with organic layer, which provides higher anti-corrosion property and a longer lifespan than that of galvanized or galvalume steel sheets.

2. The base metals for prepainted steel coil consist of cold rolled, HDGI Steel, electro-galvanized and hot-dip alu-zinc coated steel. The finish coats of prepainted steel coil can be classified into groups as follows: polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester, etc.

3. The production process has evolved from one-coating-and-one-baking to double-coating-and-double-baking, and even three-coating-and-three-baking.

4. The color of the prepainted steel coil has a very wide selection, like orange, cream-colored, dark sky blue, sea blue, bright red, brick red, ivory white, porcelain blue, etc.

5. The prepainted steel coils can also be classified into groups by their surface textures, namely regular prepainted sheets, embossed sheets and printed sheets.

Main Feature of Prime Q275 120mm Square Alloy Steel Billet

Uncoated CR steel sheet

With the features of in line with the international highest standards in demension and shape, excellent surface finish and properties, the products are mainly used in home appliance and automobile industries.

Galvanized steel sheet(include HDG and EG)

With the features of good corrosion resistance, the products are mainly used in automobile, home appliance, electronics, building and machinery manufacture industries, etc.

Precoated steel sheet

With the features of enviromental protection and good processablility, long lasting surface durability, rich in colors, the products are maily used in building, home appliance and furniture industries, etc.

Applications of Prime Q275 120mm Square Alloy Steel Billet

A. Corrugated design makes it excellent waterproof performance

B. Materials as prepainted steel sheets, galvanized steel sheets, galvalume (Al-Zn coated sheets) are available to make corrugated sheet.

C.Those material are durable, anti-corrosion in bad weather for 20-30 years based on it's Zinc(Galvanized) coating or AZ (Galvalume) coating.

D. Different shape of the sheet make it suitable for any style of buildings.

E.Easy to install, no need special tools to fix the sheet.

F.Light weight due to high strength to weight ratio of steel. Light weight means easier handling lower shipping costs, easier installation

G. Different color is availbe base on the RAL Standard make your building more beautiful.

H. We will provide the best solutions if you don't have a exact idea of the specification you want for the steel sheet based on your weather conditions, engineering structure, construction budget and so on.

Specifications of Prime Q275 120mm Square Alloy Steel Billet

Product | Billet |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.6-3.0mm |

Width | 500-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | Z30-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM 610MM |

Coil weight | 1-25MT |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Prime Q275 120mm Square Alloy Steel Billet

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: How are steel billets used in the production of oil and gas machinery?

- Steel billets are used in the production of oil and gas machinery as a primary raw material for manufacturing various components, such as gears, shafts, valves, and casings. These billets are heated and shaped through processes like forging and rolling to create the desired shape and strength needed for the machinery. Additionally, steel billets provide the necessary durability and corrosion resistance required to withstand the harsh operating conditions in the oil and gas industry.

- Q: How long do steel billets last?

- The longevity of steel billets varies depending on multiple factors, including their storage conditions and utilization. Provided that they are stored appropriately in a controlled environment with low humidity and shielded from corrosion, steel billets can endure indefinitely. Conversely, if they are exposed to harsh weather, excessive moisture, or corrosive substances, their lifespan can be significantly diminished. As for their usage, steel billets are typically melted and transformed into other steel products, such as bars, rods, and beams. The lifespan of the final product hinges on its specific application and the maintenance practices implemented. Generally, steel products are renowned for their durability and longevity, rendering them a dependable option in numerous industries.

- Q: Can steel billets be forged into complex shapes?

- Complex shapes can be achieved by forging steel billets. The process involves heating the billet to a specific temperature, usually above its recrystallization temperature, and then applying pressure to shape it. Various forging techniques like open die, closed die, or impression die forging can be used. Steel is highly malleable and can be easily shaped and deformed under heat and pressure. This property allows steel billets to be forged into intricate shapes like gears, turbine blades, automotive parts, and other components used in different industries. Forging not only shapes the billet but also enhances its mechanical properties, making it stronger and more durable. The resulting forged steel has a refined grain structure, improving its toughness, resistance to fatigue, and resistance to cracking. However, forging complex shapes from steel billets requires skilled craftsmanship and specialized equipment. The process may involve multiple steps like pre-forming, rough forging, and finish forging to achieve the desired shape and dimensions. Computer-aided design (CAD) and computer-aided manufacturing (CAM) technologies are often used to optimize the forging process and ensure precision and accuracy. To sum up, steel billets can be forged into intricate shapes. Through forging, the malleability of steel is harnessed to create components with improved mechanical properties.

- Q: How do steel billets contribute to the overall corrosion protection of a structure?

- Steel billets, which are semi-finished steel products, play a significant role in contributing to the overall corrosion protection of a structure. They contribute to corrosion protection in several ways: 1. High-quality steel composition: Steel billets are manufactured using high-quality steel that consists of various alloying elements, such as chromium, nickel, and molybdenum. These alloying elements enhance the corrosion resistance of the steel, making it less susceptible to rust and corrosion. 2. Protective coating: Steel billets are often coated with protective layers, such as zinc or epoxy coatings. These coatings act as a barrier between the steel surface and the external environment, preventing moisture, oxygen, and other corrosive substances from reaching the steel and causing corrosion. 3. Durability and strength: Steel billets are known for their high strength and durability. When used in the construction of a structure, they provide a strong foundation and structural support. This strength and durability minimize the chances of structural damage and corrosion, ensuring the longevity and stability of the structure. 4. Weldability: Steel billets are highly weldable, allowing for easy and efficient joining of steel components during construction. Proper welding techniques and materials can further enhance the corrosion resistance of the structure by maintaining the integrity and continuity of the protective coatings. 5. Maintenance and repair: In case of any damage or corrosion on the structure, steel billets can be easily replaced or repaired. This ensures that the affected area can be fixed without compromising the overall integrity and corrosion protection of the structure. Regular maintenance and repair of steel billets contribute to the long-term corrosion protection of the entire structure. In summary, steel billets contribute to the overall corrosion protection of a structure through their high-quality composition, protective coatings, durability, weldability, and ease of maintenance and repair. By incorporating steel billets into construction projects, engineers and architects can ensure the longevity, safety, and corrosion resistance of structures in various environments.

- Q: Can steel billets be used in high-temperature applications?

- Steel billets can indeed be utilized in applications that involve high temperatures. Generally, these billets are crafted from carbon steel, which possesses commendable heat resistance characteristics. Carbon steel is capable of enduring escalated temperatures without experiencing substantial deformation or strength reduction. Nonetheless, it is crucial to contemplate the particular grade and composition of the steel billets, as dissimilar alloys might have diverse temperature thresholds. Moreover, factors such as the duration of exposure to elevated temperatures, the existence of corrosive surroundings, and the mechanical loading conditions must be considered in order to ascertain the appropriateness of steel billets for high-temperature applications.

- Q: What is the role of steel billets in the shipbuilding industry?

- Steel billets are essential in the shipbuilding industry as they serve as the raw material for manufacturing various structural components of ships. These billets are used to create beams, plates, and sections that form the framework and hull of the vessels. Their high strength and durability make them ideal for withstanding the harsh marine environment and ensuring the structural integrity of the ships. Overall, steel billets are crucial in constructing reliable and safe ships for transportation and maritime operations.

- Q: How do steel billets contribute to sustainable construction?

- Steel billets contribute to sustainable construction in several ways: 1. Reduced energy consumption: Steel billets are produced using electric arc furnaces, which require less energy compared to traditional steel manufacturing processes. This results in lower greenhouse gas emissions, contributing to the reduction of carbon footprint. 2. Recyclability: Steel is one of the most recycled materials in the world, and steel billets can be recycled multiple times without losing their mechanical properties. This reduces the need for new steel production, conserves natural resources, and decreases waste disposal. 3. Strength and durability: Steel billets have high strength and durability, making them an ideal choice for constructing sustainable buildings. Their structural integrity ensures long-lasting construction, reducing the need for frequent repairs or replacements. This helps to minimize waste generation and increase the lifespan of buildings. 4. Versatility: Steel billets can be shaped and formed into various structural components, allowing for flexibility in design and construction. This adaptability facilitates the construction of sustainable buildings that can be easily modified or expanded to accommodate changing requirements, reducing the need for new construction. 5. Resistance to natural disasters: Steel billets offer excellent resistance to seismic forces, hurricanes, and other natural disasters. This makes them suitable for constructing buildings in regions prone to such events, contributing to the resilience and safety of the built environment. 6. Reduced construction time: Steel billets enable faster construction due to their prefabricated nature. This reduces the overall construction time, minimizing disruption to the environment and nearby communities. Additionally, prefabricated steel components can be easily dismantled and reused, further enhancing sustainability. In conclusion, steel billets contribute to sustainable construction by reducing energy consumption, being highly recyclable, providing strength and durability, offering design versatility, resisting natural disasters, and reducing construction time. By incorporating steel billets into construction projects, we can create more environmentally-friendly and long-lasting structures, promoting sustainability in the built environment.

- Q: How are steel billets used in the production of power transmission equipment?

- Steel billets are used in the production of power transmission equipment as they are heated and shaped into various components such as gears, shafts, and couplings. These billets provide the necessary strength and durability required for these equipment to handle high power loads and transmit energy efficiently.

- Q: Can steel billets be used in the production of pipes?

- Yes, steel billets can be used in the production of pipes. Steel billets are semi-finished metal products that can be further processed into various shapes, including pipes. The billets are heated, pierced, and elongated to form seamless pipes or rolled and welded to create welded pipes.

- Q: What are the different types of steel billet surface defects?

- There are several different types of steel billet surface defects that can occur during the manufacturing process. These defects can affect the quality and performance of the steel, and it is important to identify and address them to ensure the integrity of the final product. 1. Scale: Scale is a common defect that occurs as a result of oxidation during the heating and rolling process. It appears as a thin layer of iron oxide on the surface of the billet and can be easily removed through descaling processes. 2. Cracks: Cracks are another common defect that can occur on the surface of steel billets. They can be caused by several factors such as uneven cooling, excessive stress, or improper handling. Cracks can lead to weakened structural integrity and should be repaired or the affected billets discarded. 3. Pitting: Pitting is a defect characterized by small, shallow depressions or pits on the surface of the billet. It can be caused by a variety of factors including impurities in the steel, improper cooling, or corrosion. Pitting can lead to reduced strength and increased susceptibility to corrosion. 4. Lamination: Lamination defects occur when there are layers or separation within the billet caused by poor bonding during the manufacturing process. This defect can compromise the mechanical properties of the steel and may result in failure under stress. 5. Inclusions: Inclusions are non-metallic substances that become trapped within the billet during the manufacturing process. They can include slag, oxides, or other impurities. Inclusions can weaken the steel and reduce its ductility, making it more prone to cracking or breaking. 6. Scratches: Scratches are superficial defects that can occur during handling or transportation of the billets. While they may not greatly affect the overall structural integrity of the steel, they can lead to localized stress concentrations and potential failure in certain applications. 7. Decarburization: Decarburization is a defect that occurs when the surface of the billet loses its carbon content during the heating process. This can lead to reduced hardness and strength in the affected area, affecting the performance of the steel. It is important for manufacturers and inspectors to be aware of these different types of steel billet surface defects to ensure the production of high-quality steel products. Regular inspections, quality control measures, and appropriate corrective actions can help minimize and address these defects to ensure the desired performance and longevity of the steel.

Send your message to us

Prime Q275 120mm Square Alloy Steel Billet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords