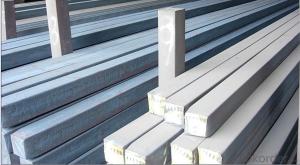

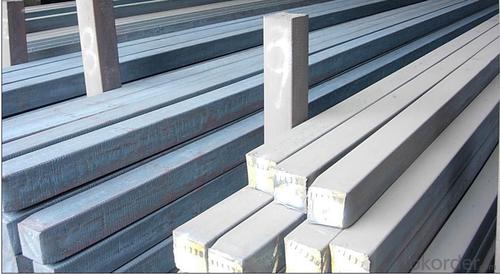

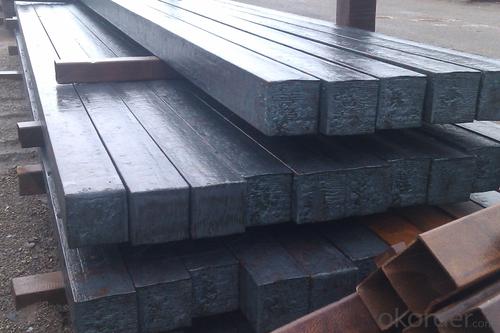

Prime Q275 130mm Square Alloy Steel Billet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Prime Q275 130mm Square Alloy Steel Billet

Description of Prime Q275 130mm Square Alloy Steel Billet

1. Prepainted steel coil is coated with organic layer, which provides higher anti-corrosion property and a longer lifespan than that of galvanized or galvalume steel sheets.

2. The base metals for prepainted steel coil consist of cold rolled, HDGI Steel, electro-galvanized and hot-dip alu-zinc coated steel. The finish coats of prepainted steel coil can be classified into groups as follows: polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester, etc.

3. The production process has evolved from one-coating-and-one-baking to double-coating-and-double-baking, and even three-coating-and-three-baking.

4. The color of the prepainted steel coil has a very wide selection, like orange, cream-colored, dark sky blue, sea blue, bright red, brick red, ivory white, porcelain blue, etc.

5. The prepainted steel coils can also be classified into groups by their surface textures, namely regular prepainted sheets, embossed sheets and printed sheets.

Main Feature of Prime Q275 130mm Square Alloy Steel Billet

Uncoated CR steel sheet

With the features of in line with the international highest standards in demension and shape, excellent surface finish and properties, the products are mainly used in home appliance and automobile industries.

Galvanized steel sheet(include HDG and EG)

With the features of good corrosion resistance, the products are mainly used in automobile, home appliance, electronics, building and machinery manufacture industries, etc.

Precoated steel sheet

With the features of enviromental protection and good processablility, long lasting surface durability, rich in colors, the products are maily used in building, home appliance and furniture industries, etc.

Applications of Prime Q275 130mm Square Alloy Steel Billet

A. Corrugated design makes it excellent waterproof performance

B. Materials as prepainted steel sheets, galvanized steel sheets, galvalume (Al-Zn coated sheets) are available to make corrugated sheet.

C.Those material are durable, anti-corrosion in bad weather for 20-30 years based on it's Zinc(Galvanized) coating or AZ (Galvalume) coating.

D. Different shape of the sheet make it suitable for any style of buildings.

E.Easy to install, no need special tools to fix the sheet.

F.Light weight due to high strength to weight ratio of steel. Light weight means easier handling lower shipping costs, easier installation

G. Different color is availbe base on the RAL Standard make your building more beautiful.

H. We will provide the best solutions if you don't have a exact idea of the specification you want for the steel sheet based on your weather conditions, engineering structure, construction budget and so on.

Specifications of Prime Q275 130mm Square Alloy Steel Billet

Product | Billet |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.6-3.0mm |

Width | 500-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | Z30-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM 610MM |

Coil weight | 1-25MT |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Prime Q275 130mm Square Alloy Steel Billet

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: What are the different surface treatments for improved surface lubrication in steel billets?

- To enhance surface lubrication, there are multiple techniques available for treating steel billets. These treatments target the reduction of friction and wear during manufacturing processes like rolling or extrusion. Some commonly used methods to improve surface lubrication in steel billets are: 1. Phosphating: By applying a phosphate coating to the steel surface, this treatment creates a thin layer of phosphate compound. Acting as a lubricant, it minimizes friction between the billet and machinery during processing. 2. Nitriding: Through the introduction of nitrogen into the steel surface, nitriding forms a nitride layer. This layer enhances the billet's surface hardness, wear resistance, and lubrication properties, reducing friction. 3. Electroplating: This treatment involves depositing a layer of metal, such as zinc or nickel, onto the surface of the steel billet. Besides improving lubrication, it also offers corrosion protection, extending the billet's lifespan. 4. Surface coating: Different types of coatings, such as Teflon or polymer-based coatings, can be applied to steel billets. These coatings create a low-friction surface, preventing sticking or galling during processing. 5. Shot peening: Shot peening is a mechanical surface treatment that bombards the steel surface with small, high-velocity metal shots. This process induces compressive stress in the surface layer, enhancing wear resistance and reducing friction. 6. Case hardening: Case hardening involves the diffusion of carbon or other alloying elements into the steel surface through heat treatment. This treatment forms a hardened outer layer, improving lubrication properties and reducing friction during processing. In summary, these surface treatments offer advantages such as reduced wear, improved efficiency, and extended tool life for steel billets. The choice of treatment depends on specific application requirements and the desired properties of the billet.

- Q: What are the main factors affecting the machinability of stainless steel billets?

- The machinability of stainless steel billets is influenced by several key factors. 1. Alloy composition: The composition of stainless steel, including the presence of various alloying elements, significantly affects its machinability. Certain elements such as sulfur, lead, and selenium can improve machinability by enhancing chip formation and reducing tool wear. On the other hand, elements like chromium and nickel, which are commonly found in stainless steel, can increase hardness and reduce machinability. 2. Hardness: The hardness of stainless steel billets plays a crucial role in determining machinability. Higher hardness levels make the material more difficult to cut, which can result in increased tool wear and reduced efficiency. Hardness can be influenced by various factors, including alloy composition, heat treatment, and mechanical processing. 3. Heat treatment: The heat treatment process employed on stainless steel billets can greatly impact their machinability. Heat treatment can alter the microstructure of the material, affecting its hardness, toughness, and ability to be machined. For example, annealing can soften the stainless steel, making it more machinable, while processes like hardening or tempering can increase hardness and reduce machinability. 4. Cutting tool selection: The choice of cutting tools used for machining stainless steel billets is crucial in achieving optimal machinability. Stainless steel is known for its tendency to work-harden, which can lead to increased cutting forces and tool wear. High-speed steel (HSS) and carbide tools are commonly used for machining stainless steel due to their superior hardness and wear resistance. 5. Cutting parameters: The selection of appropriate cutting parameters, such as cutting speed, feed rate, and depth of cut, is essential for achieving good machinability in stainless steel billets. The cutting parameters must be carefully chosen to balance the desired metal removal rate with minimizing tool wear and heat generation. Adjusting these parameters can help optimize chip formation, tool life, and surface finish. 6. Lubrication and cooling: The use of proper lubrication and cooling techniques during machining can significantly influence the machinability of stainless steel billets. Lubricants help reduce friction and heat generation, improving chip formation and extending tool life. Cooling methods, such as flood or through-tool cooling, can dissipate heat and prevent thermal damage to the workpiece and cutting tool. All these factors interact with each other to determine the machinability of stainless steel billets. A thorough understanding of these factors allows manufacturers to optimize the machining process and achieve efficient and cost-effective production of stainless steel components.

- Q: How long do steel billets typically last?

- Steel billets typically last for many years, as they are highly durable and resistant to corrosion. However, the specific lifespan of a steel billet depends on various factors such as the quality of the steel, the environment it is exposed to, and the usage conditions. With proper maintenance and care, steel billets can last for several decades.

- Q: Can steel billets be used in the manufacturing of machinery?

- Yes, steel billets can be used in the manufacturing of machinery. Steel billets are semi-finished products that can be further processed into various shapes and sizes for different applications. In machinery manufacturing, steel billets are often used as raw materials to produce components such as gears, shafts, and structural frames. The high strength and durability of steel make it an ideal choice for machinery that requires robust construction and reliable performance.

- Q: How are steel billets used in the production of aerospace structures?

- Steel billets are used in the production of aerospace structures as they are melted and cast into various shapes to create critical components such as beams, brackets, and fittings. These billets serve as the raw material that undergoes further processing, including machining, welding, and heat treatment, to meet the specific requirements and tolerances of aerospace applications. The high strength and durability of steel make it an ideal material for aerospace structures, ensuring the safety and reliability of aircraft.

- Q: What is the role of steel billets in the production of railway wagons?

- Steel billets play a crucial role in the production of railway wagons, serving as the primary raw material for manufacturing various wagon components. Essentially, steel billets are semi-finished steel products that are cast into specific shapes, typically squares or rectangles, and serve as the starting point for further processing. In the production process, steel billets are first heated to a high temperature and then passed through rolling mills to shape them into desired forms such as beams, plates, angles, channels, or other structural components. These components form the structural framework of the wagons, providing strength, durability, and stability. The exceptional strength and ability of steel billets to withstand heavy loads make them ideal for railway applications. They possess excellent mechanical properties, including high tensile strength, ensuring the wagons can endure the stresses and strains experienced during operation. The use of steel billets also allows for flexibility in design and customization, as they can be easily shaped and formed according to specific requirements. Manufacturers can produce railway wagons of various sizes, configurations, and capacities to cater to different transportation needs. Furthermore, steel billets are highly resistant to corrosion, which is particularly important for railway wagons exposed to harsh environmental conditions. This resistance helps maintain the structural integrity of the wagons, preventing premature deterioration and ensuring their long service life. Overall, steel billets are indispensable in the production of railway wagons. They provide the necessary strength, durability, and customization options required for manufacturing robust and reliable wagons that can withstand the demanding conditions of railway transportation.

- Q: What are the different types of steel alloys used for manufacturing steel billets?

- There are several different types of steel alloys that are commonly used for manufacturing steel billets. These alloys are specifically designed to offer various properties and characteristics to meet the requirements of different applications. One commonly used steel alloy for manufacturing steel billets is carbon steel. Carbon steel is an alloy that primarily consists of iron and carbon. It is known for its strength and durability, making it suitable for a wide range of applications such as construction, automotive, and machinery. Stainless steel is another type of steel alloy that is frequently used for manufacturing steel billets. It is composed of iron, chromium, and other elements such as nickel and molybdenum. Stainless steel is highly resistant to corrosion, making it ideal for applications where exposure to moisture or harsh environments is a concern, such as marine equipment, medical instruments, and kitchen utensils. Another type of steel alloy used for manufacturing steel billets is alloy steel. Alloy steel is made by adding various alloying elements such as manganese, nickel, chromium, and vanadium to the base iron. This enhances the strength, hardness, and wear resistance of the steel, making it suitable for applications that require high durability and toughness, such as aerospace components, automotive parts, and industrial machinery. Tool steel is yet another type of steel alloy commonly used for manufacturing steel billets. It is a high-carbon alloy that contains additional elements such as tungsten, molybdenum, and vanadium. Tool steel is known for its exceptional hardness, heat resistance, and wear resistance, which makes it ideal for applications that involve cutting, drilling, and shaping, such as cutting tools, drills, and molds. In summary, the different types of steel alloys used for manufacturing steel billets include carbon steel, stainless steel, alloy steel, and tool steel. Each of these alloys offers specific properties and characteristics that make them suitable for different applications across various industries.

- Q: What are the different types of surface coating methods used for steel billets?

- There are several types of surface coating methods used for steel billets, including galvanizing, electroplating, powder coating, and painting. Galvanizing involves applying a layer of zinc to the surface of the billets to provide corrosion resistance. Electroplating uses an electrical current to deposit a thin layer of metal onto the steel surface, enhancing its appearance and protecting it from corrosion. Powder coating involves applying a dry powder to the billets, which is then heated to form a protective layer. Painting is another common method, where a liquid paint is applied to the billets to provide both protection and aesthetic appeal.

- Q: How are steel billets used in the production of wire rods and bars?

- Steel billets are an essential component in the production of wire rods and bars. These billets, which are semi-finished metal products, serve as the raw material for manufacturing various types of steel products. To begin the production process, steel billets are heated to a high temperature in a furnace, known as a reheat furnace, until they reach the desired temperature for rolling. Once heated, the billets are then passed through a series of rolling mills, where they undergo hot rolling. During the hot rolling process, the steel billets are gradually shaped into wire rods or bars by repeatedly passing them through a set of rollers. This process helps to reduce the billet's cross-sectional area and increase its length, resulting in the desired shape and dimensions of the wire rods or bars. After the initial rolling, the wire rods or bars may undergo additional processes, such as cooling, surface treatment, and further shaping or cutting, depending on the specific requirements of the end product. These additional steps help to improve the mechanical properties and surface finish of the wire rods or bars. Once the wire rods or bars have been processed, they can be used in a wide range of applications. Wire rods, for example, are commonly used in the production of wires, nails, fencing, and various types of reinforcement materials. Bars, on the other hand, are often utilized in construction, manufacturing machinery, automotive parts, and other structural applications. In summary, steel billets play a crucial role in the production of wire rods and bars. They are heated and then shaped through the hot rolling process, resulting in the desired dimensions and properties of the end product. These wire rods and bars are then used in various industries for different applications, contributing to the overall development and functionality of numerous products and structures.

- Q: What are the properties and characteristics of steel billets?

- Steel billets, typically utilized in the production of various steel products, exhibit numerous properties and characteristics that render them suitable for such applications. To begin with, their exceptional strength-to-weight ratio endows steel billets with immense strength, enabling them to withstand heavy loads. This strength is derived from the steel's carbon content, which enhances its structural integrity. Furthermore, their superb heat conductivity facilitates efficient heat transfer during diverse manufacturing processes. Consequently, steel billets prove ideal for applications involving high-temperature operations, such as forging and rolling. Moreover, their remarkable machinability enables easy shaping and forming into desired products. This property is of utmost importance in the manufacturing industry, as it allows for the production of intricate and personalized steel components. Steel billets also possess outstanding ductility, enabling them to stretch and mold without fracturing. This characteristic proves vital in applications requiring bending or forming the steel into various shapes. In addition, steel billets exhibit a high resistance to corrosion, rendering them suitable for outdoor or corrosive environments. This property guarantees the durability and longevity of steel products manufactured from billets. Furthermore, steel billets can be effortlessly welded, facilitating the fabrication of large and intricate structures. Their weldability renders them versatile and adaptable to diverse construction and manufacturing needs. Lastly, steel billets boast a consistent and uniform composition, ensuring the production of high-quality and dependable steel products. This consistency is achieved through meticulous manufacturing processes and rigorous quality control measures. To conclude, steel billets possess numerous properties and characteristics that make them highly sought-after in the production of steel products. Their high strength, heat conductivity, machinability, ductility, corrosion resistance, weldability, and consistent composition deem them indispensable in various industries, including construction, automotive, and manufacturing.

Send your message to us

Prime Q275 130mm Square Alloy Steel Billet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords