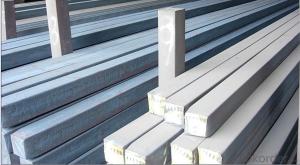

Prime Q275 140mm Square Alloy Steel Billet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Prime Q275 140mm Square Alloy Steel Billet

Description of Prime Q275 140mm Square Alloy Steel Billet

1. Prepainted steel coil is coated with organic layer, which provides higher anti-corrosion property and a longer lifespan than that of galvanized or galvalume steel sheets.

2. The base metals for prepainted steel coil consist of cold rolled, HDGI Steel, electro-galvanized and hot-dip alu-zinc coated steel. The finish coats of prepainted steel coil can be classified into groups as follows: polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester, etc.

3. The production process has evolved from one-coating-and-one-baking to double-coating-and-double-baking, and even three-coating-and-three-baking.

4. The color of the prepainted steel coil has a very wide selection, like orange, cream-colored, dark sky blue, sea blue, bright red, brick red, ivory white, porcelain blue, etc.

5. The prepainted steel coils can also be classified into groups by their surface textures, namely regular prepainted sheets, embossed sheets and printed sheets.

Main Feature of Prime Q275 140mm Square Alloy Steel Billet

They were one of several reasons for the wind to be taken out of the sails of the recent oil price momentum. Kuwait’s oil minister said that his country would only commit to a production freeze if all major producers are involved, including Iran. We also had Goldman telling us that oil markets will not rebalance at $40/bbl as it throws a lifeline to cash-strapped US producers.

If it is talk of a production freeze that is behind the rally it shows how low expectations have fallen. It is in the nature of oil people to talk the market up. Any bullish crumb is given exaggerated significance and any port in a storm will do. It is all but fact that the oil market will be tighter in the second half of this year when seasonal demand shoots up and US production continues to decline. It was the same picture last year. If OPEC and key non-OPEC production is frozen that will ensure the daily surplus will fall, but in all likelihood there will still be a surplus and there is an enormous global stockbuild to burn off.

Applications of Prime Q275 140mm Square Alloy Steel Billet

A. Corrugated design makes it excellent waterproof performance

B. Materials as prepainted steel sheets, galvanized steel sheets, galvalume (Al-Zn coated sheets) are available to make corrugated sheet.

C.Those material are durable, anti-corrosion in bad weather for 20-30 years based on it's Zinc(Galvanized) coating or AZ (Galvalume) coating.

D. Different shape of the sheet make it suitable for any style of buildings.

E.Easy to install, no need special tools to fix the sheet.

F.Light weight due to high strength to weight ratio of steel. Light weight means easier handling lower shipping costs, easier installation

G. Different color is availbe base on the RAL Standard make your building more beautiful.

H. We will provide the best solutions if you don't have a exact idea of the specification you want for the steel sheet based on your weather conditions, engineering structure, construction budget and so on.

Specifications of Prime Q275 140mm Square Alloy Steel Billet

Product | Billet |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.6-3.0mm |

Width | 500-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | Z30-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM 610MM |

Coil weight | 1-25MT |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Prime Q275 140mm Square Alloy Steel Billet

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

- Q: How are steel billets used in the manufacturing of food processing machinery?

- Food processing machinery relies on steel billets for the production of various components and structures. These billets undergo heating and rolling processes to form steel bars, rods, or sheets of different shapes and sizes. These steel products are then utilized in the construction of the framework, body, and other parts of the machinery. Steel's high strength and durability make it an ideal choice for food processing machinery, which often operates in harsh conditions and requires resistance to corrosion, wear, and high temperatures. Steel billets are carefully selected for their quality and suitability for the intended application. When constructing food processing machinery, steel billets are employed in fabricating crucial components like cutting blades, mixing paddles, conveyor belts, and grinding plates. These components are vital for the efficient processing and handling of food products, ensuring consistent quality and safety. Furthermore, steel billets are also used in manufacturing structural supports, frames, and housing for machinery. These structures provide the necessary stability, rigidity, and support to ensure the proper functioning and longevity of the food processing equipment. In conclusion, steel billets play a vital role in the manufacturing of food processing machinery as they provide the essential raw material required to create durable, reliable, and efficient equipment. The quality and characteristics of steel contribute to the performance, safety, and hygiene standards demanded in the food processing industry.

- Q: What are the different types of surface defect detection equipment for steel billets?

- There are several types of surface defect detection equipment for steel billets, including ultrasonic testing (UT), magnetic particle inspection (MPI), visual inspection, eddy current testing, and automated optical inspection (AOI). Each of these methods has its own advantages and limitations when it comes to detecting and evaluating surface defects in steel billets.

- Q: How are steel billets used in the manufacturing of kitchen appliances?

- Kitchen appliances require steel billets as they possess versatile properties and can be molded into different shapes and sizes. These billets, typically made from low carbon steel, act as the raw material for manufacturing kitchen appliances like stoves, ovens, refrigerators, and dishwashers. The production process starts by heating the steel billets to a high temperature, known as annealing, to enhance their formability and ductility. Once the desired temperature is achieved, the billets are passed through rolling mills to reduce their size and shape them accordingly. This hot rolling process forms steel sheets or plates, which can be further processed. Next, these steel sheets or plates are cut, bent, and formed into various components of kitchen appliances. For instance, the body of a refrigerator or oven is often made by shaping and welding steel sheets together to create a strong and durable structure. Similarly, the burners and grates of a stove are typically cast and machined from steel billets to acquire the desired shape. The use of steel billets in manufacturing kitchen appliances offers numerous advantages. Steel is renowned for its strength, durability, and resistance to corrosion, making it an excellent choice for appliances that endure frequent use and exposure to moisture. Additionally, steel is easy to clean and maintain, ensuring the longevity and hygiene of the appliances. Moreover, steel is a cost-effective material for kitchen appliance manufacturing. Its widespread availability and comparatively low production costs contribute to making kitchen appliances more affordable for consumers. In conclusion, steel billets play a vital role in the production of kitchen appliances by providing a versatile and cost-effective material that can be shaped, formed, and assembled into different components. Their strength, durability, and resistance to corrosion make steel billets an ideal choice for manufacturing high-quality kitchen appliances that meet the demands of modern households.

- Q: How do steel billets contribute to the energy efficiency of a structure?

- Steel billets contribute to the energy efficiency of a structure in several ways. Firstly, steel billets are a primary raw material used in the production of structural steel, which is known for its high strength-to-weight ratio. This means that steel structures can bear heavy loads without requiring excessive amounts of material, resulting in lighter and more energy-efficient structures. The reduced weight of the structure translates to lower transportation costs and less energy consumption during construction. Furthermore, steel billets can be easily molded and shaped into various forms, allowing for the design and construction of more efficient and streamlined structures. The flexibility of steel as a construction material enables engineers and architects to create innovative designs that maximize energy efficiency. For example, steel can be used to create long-span structures, reducing the need for additional support columns and optimizing natural lighting and ventilation, which in turn reduces the need for artificial lighting and HVAC systems. In addition, steel is highly durable and requires minimal maintenance over its lifespan. This durability not only extends the life of the structure but also reduces the amount of energy and resources required for repairs and replacements. Steel structures also have excellent fire resistance properties, which can contribute to energy efficiency by minimizing fire-related damages and the subsequent energy consumption associated with rebuilding or repairing. Lastly, steel is a highly recyclable material. At the end of a structure's life, steel components can be easily salvaged and recycled, reducing the demand for new steel production and conserving natural resources. The recycling process for steel is energy-efficient compared to the production of virgin steel, further reducing the carbon footprint of the structure. Overall, steel billets contribute to the energy efficiency of a structure through their high strength-to-weight ratio, flexibility in design, durability, fire resistance, and recyclability. These properties allow for the construction of lighter, more efficient structures that require less energy during construction, operation, and maintenance while minimizing environmental impact.

- Q: How do steel billets contribute to the manufacturing of HVAC systems?

- Steel billets are used in the manufacturing of HVAC systems as they provide the raw material required for fabricating various components such as ductwork, heating coils, and air conditioning units. Billets are melted down and then shaped into the desired form, allowing manufacturers to create durable and sturdy components that can withstand the demanding conditions of HVAC systems. Additionally, steel billets offer excellent thermal conductivity, allowing for efficient heat transfer within the system, ultimately contributing to the overall performance and energy efficiency of HVAC systems.

- Q: How are steel billets used in the production of reinforcement bars?

- Steel billets are the primary raw material used in the production of reinforcement bars. These billets are heated and then passed through a series of rolling mills to shape them into the desired size and shape of reinforcement bars. The rolling process also helps in improving the mechanical properties and strength of the bars. Once the bars are formed, they undergo further processes such as quenching and tempering to enhance their strength and durability. Overall, steel billets play a crucial role in the production of reinforcement bars by serving as the starting material and undergoing various manufacturing processes to produce high-quality bars used in construction and infrastructure projects.

- Q: What are the different types of non-destructive testing methods used for steel billets?

- Some of the different types of non-destructive testing methods used for steel billets include ultrasonic testing, magnetic particle testing, dye penetrant testing, eddy current testing, and visual inspection.

- Q: How are steel billets used in the manufacturing of agricultural machinery?

- Steel billets are an essential component in the manufacturing of agricultural machinery. These billets, which are semi-finished steel products, serve as the raw material for various parts and components used in agricultural machinery. One of the primary uses of steel billets in the manufacturing process is for forging and casting. Forging involves heating the billets to a high temperature and then shaping them using mechanical pressure, while casting involves pouring molten metal into a mold. Both processes allow for the creation of complex and durable components that are necessary for agricultural machinery. Steel billets are used to manufacture a wide range of agricultural machinery parts, such as engine components, transmission gears, axles, and hydraulic cylinders. These parts require excellent strength, durability, and resistance to wear, which steel billets provide. Additionally, steel's high tensile strength ensures that the machinery can withstand the demanding conditions of agricultural operations. Moreover, steel billets are used for manufacturing the frames and chassis of agricultural machinery. The frames need to be robust to support the weight and withstand the stress and vibrations generated during operation. Steel billets allow for the creation of sturdy and rigid frames that ensure the longevity and structural integrity of the machinery. Furthermore, steel billets are utilized in the production of cutting and harvesting tools, such as blades, discs, and plowshares. The exceptional hardness and sharpness of steel make it an ideal material for these tools, enabling efficient and precise agricultural operations. In summary, steel billets play a crucial role in the manufacturing of agricultural machinery. Their versatility, strength, and durability make them a suitable material for various components and parts, ensuring that the machinery can withstand the demanding conditions of agricultural operations and perform efficiently.

- Q: What are the different types of steel billet rolling defects?

- There are several types of steel billet rolling defects that can occur during the rolling process. These defects can negatively impact the quality and integrity of the finished product. Some of the most common types of steel billet rolling defects include: 1. Surface cracks: These are small cracks that appear on the surface of the billet. They can occur due to improper cooling or excessive rolling pressure. Surface cracks can compromise the strength and durability of the steel. 2. Center cracks: Center cracks occur in the inner core of the billet. They are usually caused by improper temperature control during the rolling process. Center cracks can lead to structural weaknesses and reduced performance of the steel. 3. Scalloping: Scalloping refers to the formation of shallow depressions or grooves on the surface of the billet. It usually occurs due to uneven or improper rolling pressure distribution. Scalloping can affect the appearance and surface quality of the steel. 4. Lamination: Lamination defects involve the separation of layers within the billet. They can occur due to the presence of impurities or inclusions in the steel, as well as improper heating or rolling conditions. Lamination defects can weaken the steel and increase the risk of failure. 5. Wavy edges: Wavy edges occur when the edges of the billet become uneven or distorted during the rolling process. This can be caused by improper alignment or uneven pressure distribution. Wavy edges can affect the dimensional accuracy and overall quality of the steel. 6. Surface defects: Surface defects include scratches, pits, or other imperfections on the surface of the billet. They can occur due to inadequate cleaning or handling procedures, as well as improper rolling conditions. Surface defects can impact the appearance and surface quality of the steel. Overall, these steel billet rolling defects can have significant implications for the quality, performance, and safety of the finished product. It is important for manufacturers to closely monitor the rolling process and implement proper quality control measures to minimize the occurrence of these defects.

- Q: What are the quality standards for steel billets?

- The quality standards for steel billets typically include criteria such as chemical composition, dimensional accuracy, surface finish, mechanical properties, and internal soundness. These standards ensure that the steel billets meet the required specifications for various applications and guarantee their strength, durability, and suitability for further processing.

Send your message to us

Prime Q275 140mm Square Alloy Steel Billet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords