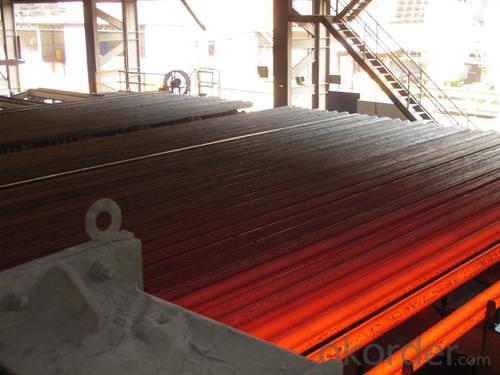

Prime Q275 100mm Square Alloy Steel Billet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Prime Q275 100mm Square Alloy Steel Billet

Description of Prime Q275 100mm Square Alloy Steel Billet

1. Prepainted steel coil is coated with organic layer, which provides higher anti-corrosion property and a longer lifespan than that of galvanized or galvalume steel sheets.

2. The base metals for prepainted steel coil consist of cold rolled, HDGI Steel, electro-galvanized and hot-dip alu-zinc coated steel. The finish coats of prepainted steel coil can be classified into groups as follows: polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester, etc.

3. The production process has evolved from one-coating-and-one-baking to double-coating-and-double-baking, and even three-coating-and-three-baking.

4. The color of the prepainted steel coil has a very wide selection, like orange, cream-colored, dark sky blue, sea blue, bright red, brick red, ivory white, porcelain blue, etc.

5. The prepainted steel coils can also be classified into groups by their surface textures, namely regular prepainted sheets, embossed sheets and printed sheets.

Main Feature of Prime Q275 100mm Square Alloy Steel Billet

Uncoated CR steel sheet

With the features of in line with the international highest standards in demension and shape, excellent surface finish and properties, the products are mainly used in home appliance and automobile industries.

Galvanized steel sheet(include HDG and EG)

With the features of good corrosion resistance, the products are mainly used in automobile, home appliance, electronics, building and machinery manufacture industries, etc.

Precoated steel sheet

With the features of enviromental protection and good processablility, long lasting surface durability, rich in colors, the products are maily used in building, home appliance and furniture industries, etc.

Applications of Prime Q275 100mm Square Alloy Steel Billet

A. Corrugated design makes it excellent waterproof performance

B. Materials as prepainted steel sheets, galvanized steel sheets, galvalume (Al-Zn coated sheets) are available to make corrugated sheet.

C.Those material are durable, anti-corrosion in bad weather for 20-30 years based on it's Zinc(Galvanized) coating or AZ (Galvalume) coating.

D. Different shape of the sheet make it suitable for any style of buildings.

E.Easy to install, no need special tools to fix the sheet.

F.Light weight due to high strength to weight ratio of steel. Light weight means easier handling lower shipping costs, easier installation

G. Different color is availbe base on the RAL Standard make your building more beautiful.

H. We will provide the best solutions if you don't have a exact idea of the specification you want for the steel sheet based on your weather conditions, engineering structure, construction budget and so on.

Specifications of Prime Q275 100mm Square Alloy Steel Billet

Product | Billet |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.6-3.0mm |

Width | 500-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | Z30-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM 610MM |

Coil weight | 1-25MT |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Prime Q275 100mm Square Alloy Steel Billet

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: What are the different types of steel billet surface treatments?

- There are several different types of steel billet surface treatments, including pickling, shot blasting, and painting. Pickling involves removing impurities and oxides from the surface of the billet using an acid solution. Shot blasting is a process in which small metallic or abrasive particles are blasted onto the surface of the billet to remove rust, scale, and other contaminants. Painting involves applying a protective coating or layer of paint to the surface of the billet to prevent corrosion and improve its appearance.

- Q: Can steel billets be used in the manufacturing of machinery?

- Yes, steel billets can be used in the manufacturing of machinery. Steel billets are semi-finished products that can be further processed into various shapes and sizes for different applications. In machinery manufacturing, steel billets are often used as raw materials to produce components such as gears, shafts, and structural frames. The high strength and durability of steel make it an ideal choice for machinery that requires robust construction and reliable performance.

- Q: What is the role of steel billets in the automotive industry?

- Steel billets are of utmost importance in the automotive industry as they are crucial in the production of various vehicle components and parts. Essentially, steel billets are semi-finished steel products that undergo further processing to achieve the desired shape and size necessary for automotive applications. One primary application of steel billets in the automotive sector is in the production of engine and transmission components. These components, including crankshafts, connecting rods, camshafts, gears, and others that require high strength and durability, rely on steel billets as raw material for forging or casting. This ensures that they can withstand the demanding conditions of engine operation. Another significant use of steel billets in the automotive industry is for the manufacturing of structural components. These components, such as chassis frames, suspension parts, and body panels, need to possess high strength and stiffness to provide safety and rigidity to the vehicle. Steel billets undergo various techniques like hot rolling, cold rolling, or extrusion to produce the necessary forms and shapes required for these structural components. Furthermore, steel billets are also employed in the production of essential fasteners like bolts, nuts, and screws, which are crucial for assembling different parts of the vehicle. These fasteners must possess excellent tensile strength and resistance to vibration and corrosion, making steel billets an ideal choice for their manufacture. Additionally, steel billets find application in the production of various other automotive components, including axles, wheel hubs, brake discs, and steering system parts. All these components require the superior mechanical properties offered by steel billets, such as high strength, toughness, and resistance to wear and tear. In conclusion, steel billets play a vital role in the automotive industry as they serve as raw material for the production of engine and transmission components, structural components, fasteners, and other crucial parts. Their exceptional mechanical properties make them an ideal choice for applications that demand high strength, durability, and reliability, ensuring the safety and performance of vehicles on the road.

- Q: How do steel billets contribute to the energy efficiency of a structure?

- Steel billets contribute to the energy efficiency of a structure in several ways. Firstly, steel billets are a primary raw material used in the production of structural steel, which is known for its high strength-to-weight ratio. This means that steel structures can bear heavy loads without requiring excessive amounts of material, resulting in lighter and more energy-efficient structures. The reduced weight of the structure translates to lower transportation costs and less energy consumption during construction. Furthermore, steel billets can be easily molded and shaped into various forms, allowing for the design and construction of more efficient and streamlined structures. The flexibility of steel as a construction material enables engineers and architects to create innovative designs that maximize energy efficiency. For example, steel can be used to create long-span structures, reducing the need for additional support columns and optimizing natural lighting and ventilation, which in turn reduces the need for artificial lighting and HVAC systems. In addition, steel is highly durable and requires minimal maintenance over its lifespan. This durability not only extends the life of the structure but also reduces the amount of energy and resources required for repairs and replacements. Steel structures also have excellent fire resistance properties, which can contribute to energy efficiency by minimizing fire-related damages and the subsequent energy consumption associated with rebuilding or repairing. Lastly, steel is a highly recyclable material. At the end of a structure's life, steel components can be easily salvaged and recycled, reducing the demand for new steel production and conserving natural resources. The recycling process for steel is energy-efficient compared to the production of virgin steel, further reducing the carbon footprint of the structure. Overall, steel billets contribute to the energy efficiency of a structure through their high strength-to-weight ratio, flexibility in design, durability, fire resistance, and recyclability. These properties allow for the construction of lighter, more efficient structures that require less energy during construction, operation, and maintenance while minimizing environmental impact.

- Q: Are steel billets used in the production of construction equipment?

- Yes, steel billets are commonly used in the production of construction equipment. Steel billets are semi-finished steel products that are typically hot-rolled or forged into various shapes and sizes. These billets serve as the raw material for manufacturing construction equipment components, such as beams, plates, rods, and structural parts. The use of steel billets in construction equipment ensures the durability, strength, and reliability of the final product, making it suitable for heavy-duty applications in the construction industry.

- Q: What are the main factors affecting the ductility of steel billets?

- There are several main factors that affect the ductility of steel billets. Firstly, one of the most significant factors is the carbon content in the steel. Higher carbon content generally reduces ductility and makes the steel more brittle. This is because carbon atoms tend to form strong bonds with iron atoms, resulting in a harder and less malleable material. Secondly, the composition of other alloying elements in the steel can also influence ductility. Elements such as manganese, silicon, and phosphorus can have different effects on the steel's ductility depending on their concentration. For example, manganese can enhance ductility while phosphorus can decrease it. Thirdly, the heat treatment process can have a significant impact on the ductility of steel billets. Rapid cooling, known as quenching, can increase the strength of the steel but may also reduce its ductility. On the other hand, annealing, which involves heating the steel and then slowly cooling it, can improve the ductility of the material. Additionally, the presence of impurities and defects in the steel can affect its ductility. Inclusions, such as non-metallic particles, can act as stress concentrators and reduce the material's ability to deform plastically. Similarly, cracks, voids, and other defects can also weaken the steel and decrease its ductility. Lastly, the grain size of the steel can influence its ductility. Fine-grained steels tend to have higher ductility compared to coarse-grained ones. This is because smaller grain boundaries provide more obstacles for dislocation movement, leading to increased resistance to deformation. Overall, the ductility of steel billets is influenced by various factors, including carbon content, alloying elements, heat treatment, impurities and defects, and grain size. Understanding and controlling these factors is essential for ensuring the desired ductility properties of steel.

- Q: How are steel billets inspected for hardness?

- Steel billets are inspected for hardness using a non-destructive testing method called ultrasonic testing. This involves the use of high-frequency sound waves that are transmitted through the billet. The reflected sound waves are then analyzed to determine the hardness of the steel. This method allows for accurate and reliable hardness inspection without causing any damage to the billet.

- Q: Billet prices skyrocketing weekend, Southern China steel prices rose?

- In December 5th, the billet price in Hebei was 2780 yuan per ton, a new high since two years and three months, a rise of more than 85% over the same period of last year.

- Q: What is the role of steel billets in the construction of high-rise buildings?

- Steel billets play a crucial role in the construction of high-rise buildings as they serve as the raw material for manufacturing structural steel sections such as beams, columns, and reinforcement bars. These sections are essential for providing strength, stability, and load-bearing capacity to the building's framework. Steel billets are heated, molded, and shaped into these sections, which are then assembled to form the structural skeleton of the building. Their high strength-to-weight ratio and durability make steel billets an ideal choice for constructing tall buildings that can withstand various weather conditions and structural loads.

- Q: What are the different surface treatments for rust prevention in steel billets?

- There are several surface treatments available for rust prevention in steel billets. These treatments aim to protect the steel surface from corrosion caused by exposure to moisture or other corrosive elements. Some of the commonly used surface treatments include: 1. Hot-dip galvanizing: This process involves immersing the steel billets in a bath of molten zinc, which creates a protective layer on the surface. The zinc coating acts as a barrier against corrosion, preventing the steel from coming into contact with corrosive elements. 2. Electroplating: In this method, a thin layer of a corrosion-resistant metal, such as zinc, nickel, or chromium, is deposited onto the steel billet surface using an electric current. The electroplated layer provides a protective barrier against rust formation. 3. Paint coatings: Applying a layer of paint on the steel billet surface can effectively prevent rust. The paint forms a protective barrier, preventing moisture or corrosive substances from reaching the steel surface. Multiple layers of paint, including primer and topcoat, are typically applied to enhance durability. 4. Powder coating: This process involves applying a dry powder, usually made of epoxy, polyester, or acrylic, to the steel billet surface. The powder is electrostatically charged and adheres to the metal, forming a protective coating when heated. Powder coating provides excellent corrosion resistance and durability. 5. Phosphating: Phosphating is a chemical treatment method that involves applying a phosphate coating to the steel surface. The phosphate layer enhances the steel's resistance to corrosion and provides a good base for subsequent paint or powder coating. 6. VCI (Vapor Corrosion Inhibitor) packaging: This method utilizes special packaging materials that release volatile corrosion inhibitors. These inhibitors create a protective atmosphere around the steel billets, preventing rust formation during storage or transportation. It is important to note that the choice of surface treatment depends on factors such as the steel's intended application, environment, and cost considerations. Each treatment method has its advantages and limitations, and it is essential to select the most appropriate treatment for effective rust prevention in steel billets.

Send your message to us

Prime Q275 100mm Square Alloy Steel Billet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords