Prime Q275 95mm Square Alloy Steel Billet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

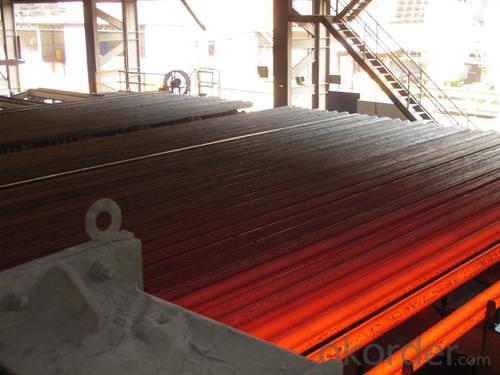

Structure of Prime Q275 95mm Square Alloy Steel Billet

Description of Prime Q275 95mm Square Alloy Steel Billet

1. Prepainted steel coil is coated with organic layer, which provides higher anti-corrosion property and a longer lifespan than that of galvanized or galvalume steel sheets.

2. The base metals for prepainted steel coil consist of cold rolled, HDGI Steel, electro-galvanized and hot-dip alu-zinc coated steel. The finish coats of prepainted steel coil can be classified into groups as follows: polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester, etc.

3. The production process has evolved from one-coating-and-one-baking to double-coating-and-double-baking, and even three-coating-and-three-baking.

4. The color of the prepainted steel coil has a very wide selection, like orange, cream-colored, dark sky blue, sea blue, bright red, brick red, ivory white, porcelain blue, etc.

5. The prepainted steel coils can also be classified into groups by their surface textures, namely regular prepainted sheets, embossed sheets and printed sheets.

Main Feature of Prime Q275 95mm Square Alloy Steel Billet

Uncoated CR steel sheet

With the features of in line with the international highest standards in demension and shape, excellent surface finish and properties, the products are mainly used in home appliance and automobile industries.

Galvanized steel sheet(include HDG and EG)

With the features of good corrosion resistance, the products are mainly used in automobile, home appliance, electronics, building and machinery manufacture industries, etc.

Precoated steel sheet

With the features of enviromental protection and good processablility, long lasting surface durability, rich in colors, the products are maily used in building, home appliance and furniture industries, etc.

Applications of Prime Q275 95mm Square Alloy Steel Billet

A. Corrugated design makes it excellent waterproof performance

B. Materials as prepainted steel sheets, galvanized steel sheets, galvalume (Al-Zn coated sheets) are available to make corrugated sheet.

C.Those material are durable, anti-corrosion in bad weather for 20-30 years based on it's Zinc(Galvanized) coating or AZ (Galvalume) coating.

D. Different shape of the sheet make it suitable for any style of buildings.

E.Easy to install, no need special tools to fix the sheet.

F.Light weight due to high strength to weight ratio of steel. Light weight means easier handling lower shipping costs, easier installation

G. Different color is availbe base on the RAL Standard make your building more beautiful.

H. We will provide the best solutions if you don't have a exact idea of the specification you want for the steel sheet based on your weather conditions, engineering structure, construction budget and so on.

Specifications of Prime Q275 95mm Square Alloy Steel Billet

Product | Billet |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.6-3.0mm |

Width | 500-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | Z30-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM 610MM |

Coil weight | 1-25MT |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Prime Q275 95mm Square Alloy Steel Billet

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: What are the potential applications of steel billets in the chemical sector?

- The chemical sector has a wide range of potential applications for steel billets. Construction of storage tanks and containers for chemical transportation and storage is one of the main uses. Steel billets are ideal for this purpose due to their high durability and ability to withstand the corrosive nature of many chemicals. In addition, steel billets can be used to construct pipes and tubing systems in chemical processing plants. These systems are crucial for transporting chemicals throughout the facility and must be able to handle high pressures and temperatures. Steel billets provide the necessary strength and durability for these applications. Steel billets also have potential in the production of chemical reactors. These reactors are essential in manufacturing various chemicals and require materials that can withstand harsh conditions. Steel billets can be used to construct these reactors, providing the strength and corrosion resistance needed. Furthermore, steel billets can be utilized in the fabrication of equipment used in the chemical sector, including heat exchangers, distillation columns, and pumps. These equipment are vital for the processing and production of chemicals, and steel billets offer the necessary strength and reliability. Overall, steel billets offer a wide range of potential applications in the chemical sector. Their durability, strength, and corrosion resistance make them an ideal choice for construction, fabrication, and equipment manufacturing in chemical processing plants, storage facilities, and more.

- Q: What are the different types of forging processes used for shaping steel billets?

- There are several types of forging processes used for shaping steel billets. Some common ones include open-die forging, closed-die forging, impression-die forging, and seamless rolled ring forging. Each process has its unique characteristics and is suitable for specific applications.

- Q: How is the quality of steel billets determined?

- The quality of steel billets is determined through a combination of physical and chemical tests. These tests are performed to ensure that the steel meets the required standards and specifications for its intended use. One of the primary methods to determine the quality of steel billets is through chemical analysis. This involves testing the composition of the steel to ensure it meets the desired levels of different elements such as carbon, manganese, silicon, and others. The chemical composition plays a crucial role in determining the strength, hardness, and other mechanical properties of the steel. In addition to the chemical analysis, various physical tests are conducted to assess the quality of steel billets. These tests include measuring the dimensions, weight, and straightness of the billets to ensure they meet the specified tolerances. Surface inspection is also performed to detect any defects, such as cracks, seams, or surface irregularities that could affect the performance of the steel. Mechanical tests are another crucial aspect of determining the quality of steel billets. These tests evaluate the mechanical properties of the steel, including its strength, ductility, toughness, and hardness. Tensile tests are commonly conducted to measure the maximum load a steel billet can withstand before breaking or deforming. Impact tests are also performed to assess the steel's ability to resist sudden shocks or impacts. Furthermore, non-destructive testing techniques are used to detect any internal defects or inconsistencies in the steel billets. These methods include ultrasonic testing, magnetic particle inspection, and radiographic testing. These tests help ensure that the steel is free from any hidden defects that could compromise its quality or structural integrity. Overall, the quality of steel billets is determined through a comprehensive evaluation that includes chemical analysis, physical tests, mechanical tests, and non-destructive testing. These methods ensure that the steel meets the required standards and specifications, providing assurance of its reliability and suitability for various applications.

- Q: How are steel billets used in the production of industrial machinery?

- Industrial machinery production relies heavily on steel billets, which serve as essential components. These billets act as the raw material that undergoes shaping and transformation processes to produce a variety of machine parts. Typically, the billets are heated and then subjected to manufacturing techniques like forging, rolling, or extrusion. Forging is a commonly employed method in the production of industrial machinery. In this process, the billets are heated to high temperatures and shaped using compressive forces applied by a forging press or hammer. This enables the steel to be molded into desired shapes and sizes, resulting in components such as gears, crankshafts, or connecting rods. Rolling is another technique that utilizes steel billets in industrial machinery production. In this method, the heated billets are passed through a series of rollers to gradually reduce their thickness and shape them into long sheets or bars. These rolled steel products can then be further processed and used in the construction of machine frames, chassis, or structural components. Extrusion, on the other hand, is a technique that also involves steel billets. In this process, the billets are heated and forced through a die to create intricate shapes with consistent cross-sections. Extruded steel parts find extensive use in the production of machine components like tubes, pipes, or profiles. Overall, steel billets play a foundational role in the manufacturing of industrial machinery. They undergo various shaping and transformation processes to produce the necessary components that contribute to the overall functionality and durability of the machinery.

- Q: What is the role of steel billets in the production of sheet metal?

- The production of sheet metal heavily relies on steel billets, which serve as the primary raw material. These billets are essentially solid bars of steel, typically rectangular or square in shape, and are produced through casting or hot rolling. Depending on the specific requirements of the sheet metal being manufactured, steel billets are produced in various sizes and lengths. To begin the production process, the steel billets are heated to a high temperature and then passed through a series of rolling mills. This rolling process is aimed at reducing the thickness of the billets and increasing their length. By applying pressure to the billets, they elongate and become thinner. This continuous rolling process is repeated multiple times until the desired thickness is achieved. Once the steel billets have been transformed into thin sheets, further processing is carried out to obtain the final sheet metal product. This may involve additional steps such as cutting, trimming, and surface treatments to enhance both the appearance and properties of the sheet metal. Steel billets are highly favored in the production of sheet metal due to their exceptional mechanical properties. Steel is renowned for its strength, durability, and malleability, making it an ideal material for sheet metal applications. By utilizing steel billets, the resulting sheet metal products possess these desirable properties. To summarize, steel billets serve as the starting point in the production of sheet metal. Through heating and rolling processes, the billets are transformed into thin sheets of steel, which are then further processed to create the final sheet metal products. The use of steel billets is crucial in ensuring the production of sheet metal with superior mechanical properties, making it an indispensable component in the manufacturing industry.

- Q: How are steel billets used in the manufacturing of pipes?

- Pipes cannot be manufactured without steel billets, which are indispensable in this process. These semi-finished products made of steel act as the raw material for pipe production. The initial step involves selecting top-notch steel and melting it in a furnace to form molten steel alloy. After the steel has melted, it is poured into molds of specific sizes and shapes to create billets. These billets then undergo a cooling and solidification process. By solidifying, the steel achieves the desired structural properties, including strength and durability. Once the steel billets have cooled down, they undergo further processing to become seamless or welded pipes. In the case of seamless pipes, the billets are heated and pierced to form a hollow tube-like structure. These pierced billets are then elongated and stretched to achieve the desired diameter and thickness of the pipe. This technique, known as hot-rolling, results in seamless pipes with consistent dimensions and improved mechanical properties. On the other hand, welded pipes are manufactured using different methods. One common method is the electric resistance welding (ERW) process. It involves heating the billets and passing them through a series of rollers to shape them into a cylindrical form. The edges of the billets are then fused together using an electric current, creating a continuous weld. Other welding techniques, such as submerged arc welding (SAW) and high-frequency induction welding (HFIW), can also be employed to manufacture welded pipes from steel billets. In both seamless and welded pipe manufacturing, the quality of the steel billets is of utmost importance. It directly impacts the integrity and performance of the final product. The appropriate selection of steel grades and strict adherence to manufacturing standards are vital to produce pipes that can withstand high pressure, extreme temperatures, and corrosive environments. To sum up, steel billets are essential in the pipe manufacturing process. They act as the starting material for pipes, whether through the hot-rolling technique for seamless pipes or various welding methods for welded pipes. Utilizing high-quality steel billets and employing precise manufacturing processes allow for the production of pipes with the necessary strength, durability, and dimensional accuracy required for a wide range of industrial and commercial applications.

- Q: I want to buy a fishing pole, I don't know how to distinguish it. Know what, please reply, thank you, [em10]!

- When it comes to the differentiation of carbon fishing rods, first of all, what are the different kinds of fishing rods containing carbon?!Carbon rod is now sold in the market are divided into three kinds, namely: carbon, pure carbon, high carbon. These three categories.1, carbon packaging, as its name implies, two layers of material, the outside layer is carbon cloth, the inside layer is glass fiber, epoxy cloth. The price of this kind of rod is lower, because it is not necessary to buy a brand because of the lower price. With a few times you can change, for beginners.2, pure carbon refers to the overall use of 30T below carbon cloth fishing rod, general 24T, 30T based, carbon content of more than 98%. Moderate price.3, high carbon refers to the overall use of more than 30T carbon cloth fishing rod, but not the whole fishing rod is made of a carbon cloth. The tonality of a fishing rod is actually modulated by a different modulus of carbon cloth.Some fishing overall with the 30T following carbon cloth, just use a very small amount of 40T or 46T carbon cloth, called high carbon rod, is actually confuse the public practice of fishing by weighing, hand identification, high carbon rod with real light, hard, two rods in a play, a ratio is obvious.

- Q: What is the maximum temperature that a steel billet can withstand?

- The maximum temperature that a steel billet can withstand depends on the specific type of steel and its composition. However, as a general rule, most steel billets can withstand temperatures up to around 1,300 to 1,500 degrees Celsius (2,372 to 2,732 degrees Fahrenheit) before experiencing significant structural changes or damage.

- Q: What are the common surface defects in steel billets during reheating?

- Common surface defects in steel billets during reheating include scale formation, decarburization, and oxidation. Scale formation occurs due to the reaction between the steel surface and the surrounding atmosphere, resulting in the formation of a layer of iron oxide. Decarburization is the loss of carbon content from the steel surface, leading to reduced strength and hardness. Oxidation refers to the reaction between oxygen and the steel surface, causing the formation of iron oxide and potentially weakening the material. These defects can affect the quality and performance of the steel billet if not properly addressed.

- Q: How do steel billets contribute to the energy sector?

- Steel billets are an essential component in the energy sector for various reasons. Firstly, they are used in the construction of power plants and energy infrastructure. Steel billets are often used to fabricate structures such as beams, columns, and support systems that are critical for the stability and safety of these facilities. These structures provide the necessary framework to house generators, turbines, and other equipment required for energy production. Moreover, steel billets are used in the manufacturing of pipelines and storage tanks for the transportation and storage of various energy resources. Whether it is oil, natural gas, or even renewable energy sources like hydrogen, steel billets are used to create durable and reliable pipeline systems that can withstand high pressures and harsh environmental conditions. Similarly, steel billets are used in the construction of storage tanks that hold energy resources, ensuring their safe storage and easy access when needed. Steel billets also play a vital role in the production of wind turbines. The towers of wind turbines are often made from steel billets due to their high strength and durability. These towers support the blades and nacelle, which house the generator and other components. The ability of steel billets to withstand extreme weather conditions and support the weight of the turbine is crucial for the efficient and reliable generation of wind energy. Furthermore, steel billets are used in the manufacturing of equipment and machinery utilized in the extraction and exploration of energy resources. For example, drilling rigs and equipment used in oil and gas exploration are often constructed using steel billets due to their high tensile strength and resistance to corrosion. This enables efficient and safe drilling operations, contributing to the overall energy production process. In conclusion, steel billets contribute significantly to the energy sector by providing the necessary infrastructure, pipelines, storage tanks, and equipment required for energy production, transportation, and exploration. Their strength, durability, and versatility make them an essential component in the construction and functioning of power plants, pipelines, wind turbines, and various other energy-related applications.

Send your message to us

Prime Q275 95mm Square Alloy Steel Billet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords