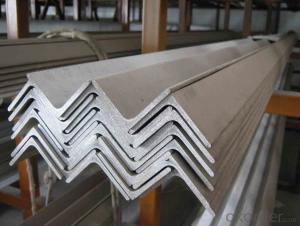

Steel Equal Angle 20MM-250MM GB Q235 20-250MM

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering high quality Hot Rolled Steel I-Beams at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

According to the needs of different structures, Angle can compose to different force support component, and also can be the connections between components. It is widely used in various building structures and engineering structures such as roof beams, bridges, transmission towers, hoisting machinery and transport machinery, ships, industrial furnaces, reaction tower, container frame and warehouse etc

Product Advantages:

OKorder's Steel I-Beams are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: Q195 – 235

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

Sizes: 25mm-250mm | ||||||||||||

a*t | ||||||||||||

25*2.5-4.0 | 70*6.0-9.0 | 130*9.0-15 | ||||||||||

30*2.5-6.6 | 75*6.0-9.0 | 140*10-14 | ||||||||||

36*3.0-5.0 | 80*5.0-10 | 150*10-20 | ||||||||||

38*2.3-6.0 | 90*7.0-10 | 160*10-16 | ||||||||||

40*3.0-5.0 | 100*6.0-12 | 175*12-15 | ||||||||||

45*4.0-6.0 | 110*8.0-10 | 180*12-18 | ||||||||||

50*4.0-6.0 | 120*6.0-15 | 200*14-25 | ||||||||||

60*4.0-8.0 | 125*8.0-14 | 250*25 | ||||||||||

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: The products are invoicing on theoritical weight or on actual weight?

A3: We can do it in both manners, according to the customers' request.

- Q: How are steel billets used in the production of heat exchangers?

- Steel billets are an essential component in the production of heat exchangers. Heat exchangers are devices that transfer heat between two or more fluids, such as air and water, without them coming into direct contact. Steel billets, which are semi-finished metal products, serve as the raw material for manufacturing the various components of heat exchangers. Firstly, steel billets are used to create the tubes and pipes that form the primary framework of heat exchangers. These tubes are designed to withstand high pressures and temperatures while efficiently transferring heat. Steel, with its high strength and thermal conductivity, is an ideal material for this purpose. Next, the steel billets are processed through various techniques such as hot rolling, forging, or extrusion to shape them into the required dimensions. This process ensures that the tubes and pipes have the desired diameter, thickness, and length, which are crucial factors in determining the heat transfer efficiency of the heat exchanger. Additionally, steel billets are also used to produce the fins and plates of heat exchangers. Fins are thin, elongated structures that increase the surface area of the heat exchanger, allowing for enhanced heat transfer. Steel billets are shaped and cut into fins, which are then attached to the tubes or plates. These fins provide additional contact points for heat transfer and help improve the overall efficiency of the heat exchanger. Moreover, steel billets are used in the production of headers and manifolds, which are crucial components for the distribution and collection of fluids within the heat exchanger. These headers ensure that the fluids flow through the tubes and fins in a controlled manner, maximizing heat transfer and minimizing pressure losses. The strength and durability of steel make it a suitable material for these critical components. In conclusion, steel billets play a vital role in the production of heat exchangers. They are used to manufacture the tubes, pipes, fins, headers, and manifolds, which are all essential components of a heat exchanger. The use of steel ensures the durability, strength, and thermal conductivity required for efficient heat transfer in these devices.

- Q: How do steel billets contribute to the manufacturing of water and wastewater treatment equipment?

- Steel billets play a crucial role in the manufacturing of water and wastewater treatment equipment. These billets are essentially semi-finished steel products that are used as raw materials for various industrial applications. When it comes to the water and wastewater treatment industry, steel billets are utilized in the production of key components such as tanks, pipes, valves, and pumps. One of the primary reasons steel billets are favored in this industry is due to their excellent strength and durability. Water and wastewater treatment equipment are subjected to harsh operating conditions, including exposure to corrosive chemicals, high pressure, and extreme temperatures. Steel billets, made from high-quality materials such as carbon steel or stainless steel, offer the necessary strength and resistance to withstand these demanding environments. Furthermore, steel billets can be easily fabricated and formed into different shapes and sizes, making them highly versatile for manufacturing water and wastewater treatment equipment. These billets can be forged, rolled, or extruded to create components with precise specifications, ensuring a perfect fit and optimal functionality. The corrosion resistance of stainless steel billets is particularly valuable in water and wastewater treatment equipment. These billets are highly resistant to rust and corrosion, preventing contamination of the water supply and ensuring the longevity of the equipment. Stainless steel billets are also hygienic, making them suitable for applications where maintaining water quality and cleanliness is of utmost importance. Additionally, steel billets offer cost-effectiveness in the manufacturing process. The abundance of steel as a material and its recyclability make it a cost-efficient choice for producing water and wastewater treatment equipment. The long lifespan of steel components also reduces the need for frequent replacements, resulting in lower maintenance and operational costs. In summary, steel billets are essential in the manufacturing of water and wastewater treatment equipment due to their strength, durability, versatility, corrosion resistance, and cost-effectiveness. These billets provide the necessary raw materials to create robust and reliable components that can withstand the challenging conditions of the water treatment industry.

- Q: What do you mean by adding carbon to a table tennis racket?

- The addition of carbon fibers increases the elasticity of the racket so as to increase the strength of the strike ball

- Q: What are the different methods of shaping steel billets?

- There are several different methods of shaping steel billets, each with its own advantages and applications. Some of the common methods include forging, rolling, extrusion, and casting. 1. Forging: Forging is a process in which the steel billet is shaped by applying pressure through the use of hammers or presses. This method allows for precise shaping and can produce complex shapes with high strength and durability. Forging is commonly used in manufacturing components for automotive, aerospace, and construction industries. 2. Rolling: Rolling is a process that involves passing the steel billet through a series of rollers to reduce its thickness and shape it into various forms such as sheets, plates, or bars. This method is highly efficient and can produce large quantities of steel products with consistent dimensions and surface finish. Rolling is commonly used in the production of structural steel, pipes, and tubes. 3. Extrusion: Extrusion is a process in which the steel billet is forced through a die to create a desired shape. This method is particularly suitable for producing long and continuous profiles with complex cross-sections, such as rods, tubes, and wire. Extrusion allows for precise control over the shape and dimensions of the final product and is commonly used in the manufacturing of aluminum window frames, automotive parts, and electrical conductors. 4. Casting: Casting is a method in which molten steel is poured into a mold and allowed to solidify into the desired shape. This process is versatile and can produce intricate and large-scale components with minimal material waste. Casting is commonly used in the production of steel ingots, pipes, and large structural components. These methods of shaping steel billets offer different advantages in terms of efficiency, precision, and versatility. The choice of method depends on the specific requirements of the desired steel product, including size, shape, strength, and cost-effectiveness.

- Q: What are the properties of alloy steel billets?

- Alloy steel billets are highly sought after in various industries due to their numerous desirable properties. Chief among these is their exceptional strength and toughness, which is attributed to the presence of alloying elements like chromium, nickel, molybdenum, and vanadium. This heightened strength enables the billets to withstand heavy loads and high temperatures, making them ideal for applications that demand resistance to wear and tear. Furthermore, alloy steel billets possess excellent corrosion resistance, rendering them perfect for use in harsh environments or exposure to chemicals. This resistance to corrosion not only extends the lifespan of the billets but also ensures their durability over time. Moreover, alloy steel billets exhibit good machinability, allowing them to be easily shaped, formed, and fabricated into various products or components. This quality facilitates the creation of intricate and complex designs, making them versatile for use in automotive, construction, and manufacturing industries. Another noteworthy property of alloy steel billets is their ability to undergo heat treatment. This process enables the adjustment of their mechanical properties, such as hardness and ductility, to meet specific requirements. Heat treatment enhances the strength and toughness of the billets, making them even more suitable for heavy-duty applications. Lastly, alloy steel billets possess excellent weldability, enabling them to be easily joined together through various welding techniques. This characteristic adds to their versatility and allows for the construction of larger structures or the fabrication of complex assemblies. In conclusion, the properties of alloy steel billets, including strength, corrosion resistance, machinability, heat treatability, and weldability, make them extremely valuable in industries where high performance and durability are crucial.

- Q: I want to buy a fishing pole, I don't know how to distinguish it. Know what, please reply, thank you, [em10]!

- When it comes to the differentiation of carbon fishing rods, first of all, what are the different kinds of fishing rods containing carbon?!Carbon rod is now sold in the market are divided into three kinds, namely: carbon, pure carbon, high carbon. These three categories.1, carbon packaging, as its name implies, two layers of material, the outside layer is carbon cloth, the inside layer is glass fiber, epoxy cloth. The price of this kind of rod is lower, because it is not necessary to buy a brand because of the lower price. With a few times you can change, for beginners.2, pure carbon refers to the overall use of 30T below carbon cloth fishing rod, general 24T, 30T based, carbon content of more than 98%. Moderate price.3, high carbon refers to the overall use of more than 30T carbon cloth fishing rod, but not the whole fishing rod is made of a carbon cloth. The tonality of a fishing rod is actually modulated by a different modulus of carbon cloth.Some fishing overall with the 30T following carbon cloth, just use a very small amount of 40T or 46T carbon cloth, called high carbon rod, is actually confuse the public practice of fishing by weighing, hand identification, high carbon rod with real light, hard, two rods in a play, a ratio is obvious.

- Q: How do steel billets contribute to the manufacturing of renewable energy equipment?

- Steel billets are an essential component in the manufacturing of renewable energy equipment, such as wind turbines and solar panels. These billets are used to create sturdy and durable structures, including tower bases for wind turbines and frames for solar panels. Additionally, steel billets are crucial in the production of transmission and distribution infrastructure required for renewable energy systems. Their strength and versatility make them an indispensable material in the renewable energy industry, enabling the efficient and reliable generation of green energy.

- Q: How are steel billets used in the production of railway tracks?

- Steel billets are the raw materials used in the production of railway tracks. They are heated, shaped, and rolled to form long, flat bars known as rails. These rails are then laid on the trackbed, forming the foundation for the tracks on which trains run.

- Q: How are steel billets marked for identification?

- Steel billets are marked for identification using various techniques and methods. One common method is through the use of marking stamps or dies. These stamps or dies contain specific alphanumeric characters or symbols that are pressed onto the surface of the billet. This creates a permanent and visible mark that can be easily read and identified. Another method is the use of paint or ink marking. This involves applying a specific color or pattern onto the surface of the billet using paint or ink. This mark can then be visually inspected and matched with the corresponding identification code. In addition to these manual methods, some steel billets are marked using laser engraving or etching. This involves using a laser beam to remove a thin layer of material from the surface of the billet, creating a permanent and precise identification mark. Laser marking is highly accurate and can produce detailed marks, including barcodes or QR codes, which can be easily scanned for identification purposes. Furthermore, some steel billets may also have identification marks applied during the manufacturing process. These marks can include information such as the steel grade, batch number, manufacturer's logo, or any other relevant information. Such marks are typically made using hot stamping, embossing, or engraving techniques, ensuring durability and visibility. Overall, steel billets are marked for identification using a combination of manual techniques, such as marking stamps or paint marking, as well as advanced methods like laser engraving or etching. These identification marks are crucial for traceability, quality control, and ensuring the proper handling and usage of steel billets in various industrial applications.

- Q: What are the main uses of steel billets?

- Steel billets are primarily used as raw material in the manufacturing of various steel products, including bars, rods, wire, tubes, and structural components. They are also commonly utilized in the production of seamless pipes, automotive parts, machinery, and construction materials.

Send your message to us

Steel Equal Angle 20MM-250MM GB Q235 20-250MM

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords