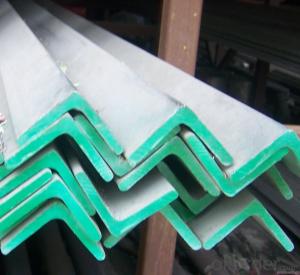

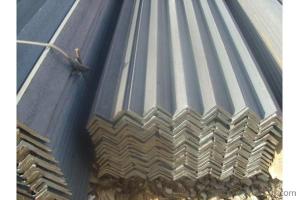

Stainless Steel Angle Iron

Stainless Steel Angle Iron Related Searches

Stainless Steel Angles Aluminum Angle Iron Stainless Steel Iron Galvanized Steel Angle Stainless Steel Eye Annealing Stainless Steel Angle Aluminum Aluminum Angle Annealed Stainless Steel Stainless Steel Anklet Stainless Steel Art Stainless Steel Anchors Stainless Steel Hinge Bending Stainless Steel Stainless Steel Siding Stainless Steel Tank Range Stainless Steel Anklet Stainless Steel Stainless Steel Bangles Stainless Steel Range Stainless Steel Jewlery Stainless Steel Jewelery Stainless Steel Drilling Stainless Steel Drill Stainless Steel Island Metal Stainless Steel Stainless Steel Elements Stainless Steel Gun Stainless Steel Jewellery Stainless Steel MagnetStainless Steel Angle Iron Supplier & Manufacturer from China

Stainless Steel Angle Iron is a type of metal product made from stainless steel, which is known for its corrosion resistance, durability, and strength. This product is available in various sizes and grades, making it suitable for a wide range of applications. Stainless Steel Angle Iron is commonly used in construction, manufacturing, and other industries where high-quality, long-lasting materials are required. Its versatility and resistance to harsh conditions make it an ideal choice for structural support, framing, and other load-bearing applications.In various industries, Stainless Steel Angle Iron is utilized for its ability to withstand extreme temperatures and corrosive environments. It is often employed in marine applications, food processing facilities, and chemical plants, where its resistance to corrosion and durability are critical. This product can be found in the construction of bridges, buildings, and other infrastructure projects, as well as in the fabrication of machinery and equipment that demands high-performance materials.

Okorder.com is a leading wholesale supplier of Stainless Steel Angle Iron, offering a vast inventory of this product to cater to the needs of various industries. With a commitment to quality and customer satisfaction, Okorder.com ensures that the Stainless Steel Angle Iron they provide meets the highest standards of performance and reliability. Their extensive stock allows customers to find the exact specifications and quantities they require, making Okorder.com a trusted source for this essential material.

Hot Products