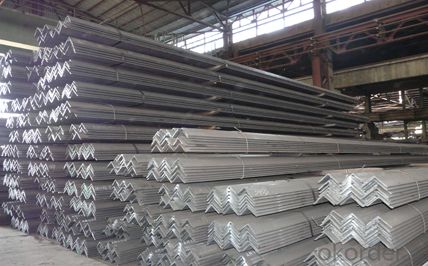

Equal / L Shaped / Unequal Mild Steel Angle Iron

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

OKorder is offering Equal / L Shaped / Unequal Mild Steel Angle Iron at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to African, South American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Equal / L Shaped / Unequal Mild Steel Angle Iron are ideal for structural applications and are widely used a variety of architectural and engineering structures, such as beams, bridges, ship; transmission tower, reaction tower; lifting transportation machinery; industrial furnace; container frame, warehouse goods shelves, etc

Product Advantages:

OKorder's Equal / L Shaped / Unequal Mild Steel Angle Iron are durable, strong, and wide variety of sizes.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Grade: Q195 – 235

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

EQUAL ANGLES SIZES |

| ||

a(mm) | a1(mm) | thickness(mm) | length |

25 | 25 | 2.5---3.0 | 6M/12M |

30 | 30 | 2.5---4.0 | 6M/12M |

38 | 38 | 2.5 | 6M/12M |

38 | 38 | 3.0---5.0 | 6M/12M |

40 | 40 | 3.0---6.0 | 6M/12M |

50 | 50 | 3 | 6M/12M |

50 | 50 | 3.7---6.0 | 6M/9M/12M |

60 | 60 | 5.0---6.0 | 6M/9M/12M |

63 | 63 | 6.0---8.0 | 6M/9M/12M |

65 | 65 | 5.0---8.0 | 6M/9M/12M |

70 | 70 | 6.0---7.0 | 6M/9M/12M |

75 | 75 | 5.0---10.0 | 6M/9M/12M |

80 | 80 | 6.0---10.0 | 6M/9M/12M |

90 | 90 | 6.0---10.0 | 6M/9M/12M |

100 | 100 | 6.0---12.0 | 6M/9M/12M |

120 | 120 | 8.0-12.0 | 6M/9M/12M |

125 | 125 | 8.0---12.0 | 6M/9M/12M |

130 | 130 | 9.0-12.0 | 6M/9M/12M |

140 | 140 | 10.0-16.0 | 6M/9M/12M |

150 | 150 | 10---15 | 6M/9M/12M |

160 | 160 | 10---16 | 6M/9M/12M |

180 | 180 | 12---18 | 6M/9M/12M |

200 | 200 | 14---20 | 6M/9M/12M |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will arrange production. The normal sizes with the normal grade can be produced within one month. The specific shipping date is dependent upon international and government factors, the delivery to international main port about 45-60days.

Images:

- Q: What are the common bending or forming processes used for steel angles?

- The common bending or forming processes used for steel angles include cold bending, hot bending, roll forming, and press brake forming.

- Q: How do steel angles contribute to the overall stability of a building?

- Steel angles are an essential component of the overall stability of a building. They provide structural support and enhance the load-bearing capacity of the building framework. The angle shape of steel angles allows them to efficiently distribute and transfer the loads imposed on the structure, such as the weight of the floors, walls, and the roof, to the foundation. One of the key contributions of steel angles to the stability of a building is their ability to resist bending and buckling forces. The L-shaped design of steel angles helps to prevent the structural members from collapsing or deforming under heavy loads or external pressures. This resistance to bending and buckling ensures that the building remains structurally sound and stable, even in adverse conditions such as earthquakes or strong winds. Furthermore, steel angles are often used as bracing elements to provide lateral stability to the building. They are strategically placed in areas that require reinforcement against horizontal forces, such as wind or seismic activity. By connecting different structural components, steel angles help to distribute these lateral forces throughout the building, preventing excessive movement or deformation and maintaining the overall stability of the structure. In addition to their role in load-bearing and bracing, steel angles also contribute to the overall stability of a building through their durability and resistance to corrosion. Steel angles are typically made from high-strength steel, which offers excellent structural integrity and long-term reliability. This durability ensures that the building can withstand the test of time and remain stable throughout its lifespan. Overall, steel angles play a crucial role in enhancing the overall stability of a building. Their ability to resist bending and buckling forces, provide lateral stability, and their durability make them an integral part of the building's structural system. By effectively distributing and transferring loads, steel angles ensure that the building remains safe, secure, and stable, ensuring the well-being of its occupants and the longevity of the structure.

- Q: How do you determine the required length of a steel angle for a specific application?

- In order to determine the necessary length of a steel angle for a particular application, several factors must be taken into consideration. 1. Load requirements: The first step is to calculate the maximum load that the angle will need to support. This includes the weight of the object or structure it will be holding, as well as any additional live loads like wind or snow. By determining the load requirement, you can determine the appropriate strength and size of the angle. 2. Structural analysis: Conduct a structural analysis of the intended application to determine the forces and stresses that will be applied to the steel angle. This analysis will help determine the necessary properties of the angle, such as its moment of inertia, section modulus, and bending capacity. 3. Material selection: Select the appropriate steel material for the application based on its mechanical properties, such as yield strength, tensile strength, and ductility. Different grades of steel offer varying levels of strength and durability, so it is important to choose the right material to ensure the angle can withstand the required loads. 4. Design codes and standards: Refer to relevant design codes and standards, such as those established by organizations like the American Institute of Steel Construction (AISC) or the Eurocode, to ensure compliance with industry regulations and guidelines. These codes provide specific formulas and procedures for calculating the required length and size of the angle based on the load and structural analysis. 5. Fabrication considerations: Take into account any limitations or constraints in the fabrication process that may affect the length of the steel angle. For instance, standard lengths of steel angles may be available, so it may be necessary to choose a length that is readily accessible or can be easily obtained through custom fabrication. 6. Consultation with professionals: If there are any uncertainties in determining the required length of a steel angle, it is recommended to seek advice from a structural engineer or a professional experienced in steel design. They can offer expert guidance and ensure that the angle is appropriately sized and designed for the specific application. By considering these factors and following a systematic approach, it is possible to determine the necessary length of a steel angle that fulfills the specific requirements of the application.

- Q: What is the maximum span for a steel angle beam?

- The maximum span for a steel angle beam depends on various factors such as the load it is intended to support, the dimensions of the beam, and the type of steel being used. It is best to consult engineering tables, codes, or a structural engineer to determine the maximum span for a specific steel angle beam in a given application.

- Q: What are the different types of connections used for steel angles in structural applications?

- There are several types of connections that are commonly used for steel angles in structural applications. These connections are crucial for ensuring the stability and strength of the overall structure. 1. Welded connections: Welding is one of the most common methods used to connect steel angles. It involves melting the edges of the steel angles together to form a strong bond. Welded connections are typically used in applications where high strength and rigidity are required. 2. Bolted connections: Bolted connections involve using bolts and nuts to secure the steel angles together. This type of connection provides flexibility as it allows for disassembly and reassembly if needed. Bolted connections are often used in situations where ease of installation and maintenance is important. 3. Riveted connections: Riveting is a traditional method of joining steel angles. It involves inserting a rivet through holes in the steel angles and then flaring the ends to secure them in place. Riveted connections are known for their durability and resistance to corrosion. However, they are less commonly used today due to the time-consuming installation process. 4. Clip connections: Clip connections involve using metal clips or brackets to attach the steel angles. These clips are typically welded or bolted to the steel angles and provide a quick and efficient method of connection. Clip connections are often used in applications where speed and ease of installation are important factors. 5. Gusset plate connections: Gusset plates are steel plates that are used to connect steel angles at their intersection points. They are typically welded or bolted to the angles and provide additional strength and stability to the connection. Gusset plate connections are commonly used in situations where larger forces and moments need to be transferred. Each type of connection has its own advantages and disadvantages, and the choice of connection method depends on several factors including the structural requirements, loadings, and the specific application. It is important to consider the design and engineering specifications to ensure that the chosen connection method is suitable for the intended use in structural applications.

- Q: How do steel angles perform in cold weather conditions?

- Steel angles perform well in cold weather conditions due to their high durability and strength. The properties of steel, such as its ability to withstand extreme temperatures and resist deformation, make it an ideal material for various applications in cold environments. Steel angles are commonly used in construction, infrastructure, and manufacturing industries, where they provide structural support and stability. In cold weather, steel angles maintain their structural integrity, ensuring the safety and longevity of the structures they are used in. Additionally, steel has a low thermal expansion coefficient, meaning it does not contract or expand significantly with temperature changes, making it less susceptible to warping or cracking in freezing conditions. Overall, steel angles are a reliable choice for cold weather conditions, offering excellent performance and reliability.

- Q: Can steel angles be used for window frames?

- Yes, steel angles can be used for window frames. Steel angles provide stability, strength, and durability, making them a suitable choice for supporting and framing windows.

- Q: Can steel angles be used in agricultural applications?

- Yes, steel angles can be used in agricultural applications. Steel angles are versatile and durable structural components that can be used in various agricultural applications such as constructing farm buildings, barns, sheds, and livestock enclosures. They provide strength and stability to the structures, making them suitable for withstanding the heavy loads and harsh weather conditions commonly found in agricultural environments. Additionally, steel angles can be easily welded or bolted together, allowing for flexibility and ease of construction. Their corrosion-resistant properties also make them ideal for outdoor agricultural applications where exposure to moisture and chemicals is common. Overall, steel angles are a reliable and cost-effective choice for agricultural construction needs.

- Q: How do steel angles perform under impact or dynamic loading conditions?

- Steel angles are known for their exceptional strength and durability, making them highly capable of withstanding impact or dynamic loading conditions. When subjected to sudden forces or dynamic loads, steel angles exhibit resistance to deformation, bending, and fracture, thanks to their high tensile and yield strengths. The shape of steel angles, with their L-shaped cross-section, adds to their structural integrity and ability to resist impact. The flanges of the angle distribute the load evenly, effectively transferring the forces to the supporting structure. This design feature allows steel angles to efficiently absorb and distribute the impact energy, reducing the risk of failure or structural damage. Steel angles also possess excellent fatigue resistance, enabling them to endure repeated or cyclic loading without weakening or experiencing fatigue failure. This is crucial in applications where dynamic or fluctuating loads are prevalent, such as bridges, cranes, machinery, and various structural components subject to vibrations or dynamic forces. Moreover, steel angles can be further enhanced through various techniques, such as heat treatment or alloying, to improve their impact resistance and toughness. These methods can increase the hardness and strength of the angle, making it even more capable of withstanding severe impact or dynamic loading conditions. Overall, steel angles are a reliable choice for applications involving impact or dynamic loading conditions. Their combination of high strength, structural integrity, and fatigue resistance allows them to perform exceptionally well under such circumstances, ensuring the safety and longevity of the structures they are incorporated into.

- Q: What is the maximum length for a steel angle bracket?

- The maximum length for a steel angle bracket can vary depending on the manufacturer and the specific design of the bracket. However, in general, steel angle brackets are commonly available in lengths ranging from 1 inch to 8 feet or more. It's important to note that longer brackets may be more prone to bending or flexing under heavy loads, so it's essential to consider the intended application and weight-bearing requirements when selecting the appropriate length for a steel angle bracket. Additionally, consulting the manufacturer's guidelines and specifications is recommended to ensure the bracket's maximum length is not exceeded, as this could compromise its structural integrity.

Send your message to us

Equal / L Shaped / Unequal Mild Steel Angle Iron

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords