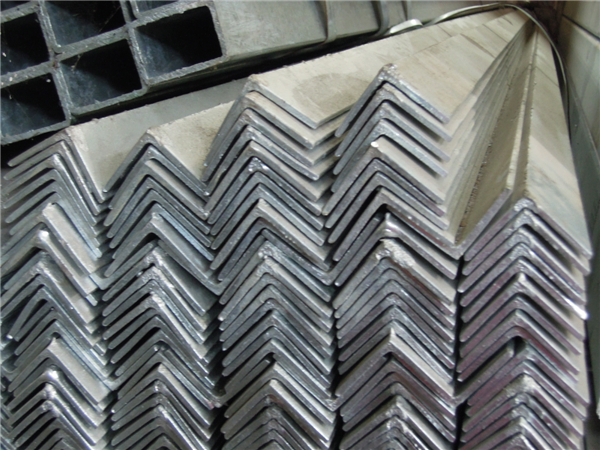

Unequal Leg and Unequal Thickness Angle Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 PCS

- Supply Capability:

- 450000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Name: Angle steel,Steel angle

Type of Angles:Unequal leg and unequal thickness angle steel

Unequal leg and unequal thickness angle steel Main steel grades: S355JR,Q345B,St52-3,S235JR,A283 Grade C,A36,

St372,Q235B,SS400,A,B,AH32,AH36

Steel standard: JIS G3192,GB 9788-88

Main application:Unequal Leg and Unequal Thickness Angle Steels are used to build ship and vessels and other steel structures

Unequal Leg and Unequal Thickness Angle Steel Rolling range: Equal-leg angles 75*75*6mm-250*250*35mm,Unequal-leg angles 100*75*7mm-200*100*16mm,unequal leg and unequal thickness angles 200*90*9*14mm-450*125*11.5*18mm.

Unequal Leg and Unequal Thickness Angle Steel Surface Treatment: Hot rolled and Coated or Shot blasting and painting

Unequal Leg and Unequal Thickness Angle Steel Supply Ability: 50000 Tons per month

Unequal Leg and Unequal Thickness Angle Steel Additional service:Shot blasting and painting,Cutting and welding as per user’s request.

- Q: How is steel tubing used in the manufacturing of automobile exhaust systems?

- Steel tubing is commonly used in the manufacturing of automobile exhaust systems due to its durability, heat resistance, and ability to withstand high temperatures. It is used to create the exhaust pipes, which transport the exhaust gases from the engine to the rear of the vehicle. Additionally, steel tubing is also utilized for the construction of various components within the exhaust system, such as mufflers and catalytic converters, to ensure proper functioning and longevity of the system.

- Q: What are the uses of steel in the oil and gas industry?

- Steel is widely used in the oil and gas industry due to its exceptional strength, durability, and resistance to corrosion. It is primarily utilized for constructing pipelines, drilling equipment, and storage tanks. Steel pipes are used to transport crude oil, natural gas, and other fluids over long distances, ensuring safe and efficient delivery. Additionally, steel is employed in the fabrication of platforms, rigs, and subsea structures, providing a sturdy foundation for offshore drilling operations. Its versatility and reliability make steel an essential material in the oil and gas industry.

- Q: What are the different types of steel clamps and their uses?

- There are several types of steel clamps with various uses. Some common types include C-clamps, bar clamps, pipe clamps, and spring clamps. C-clamps are versatile and have a wide opening, making them suitable for general woodworking and metalworking tasks. Bar clamps are longer and can apply even pressure across a larger area, ideal for securing large pieces during glue-ups. Pipe clamps are designed to hold together pipes and are commonly used in plumbing and construction projects. Spring clamps are smaller and lighter, often used for temporary or light-duty applications like holding down a tarp or securing a workpiece temporarily.

- Q: What are the different types of steel tanks and containers available?

- There are several types of steel tanks and containers available, including above-ground storage tanks, underground storage tanks, pressure vessels, intermediate bulk containers (IBCs), and shipping containers. Each type serves a specific purpose and is designed to meet different storage or transportation needs.

- Q: What are the different types of steel products used in the energy sector?

- Some of the different types of steel products used in the energy sector include pipes and tubes for oil and gas transportation, structural steel for power plant construction, steel plates for offshore drilling platforms, and steel wires for electrical transmission lines.

- Q: What are the main properties of steel?

- The main properties of steel include high tensile strength, excellent durability, good heat resistance, and the ability to be easily shaped and welded. It is known for its hardness and toughness, making it suitable for a wide range of applications in construction, manufacturing, and automotive industries. Steel also exhibits good electrical and thermal conductivity, along with corrosion resistance, making it a popular choice for various structural and engineering purposes.

- Q: How is steel used in the aerospace industry?

- Steel is used in the aerospace industry for various purposes, including the construction of aircraft structures, engine components, and landing gears. Its high strength-to-weight ratio and excellent durability make it suitable for withstanding extreme conditions and ensuring the safety and reliability of aerospace vehicles.

- Q: How do steel products contribute to the construction of theme-based water parks?

- Steel products play a crucial role in the construction of theme-based water parks due to their strength, durability, and versatility. Steel is commonly used in the framework, supports, and structures of water slides, wave pools, and other attractions. It provides the necessary stability and structural integrity to withstand the dynamic forces exerted by water and the continuous use by visitors. Additionally, steel can be shaped and fabricated into various forms, allowing for intricate and captivating designs that enhance the overall theme and aesthetics of the water park.

- Q: What are the applications of stainless steel in the food industry?

- Stainless steel has numerous applications in the food industry due to its unique properties. It is commonly used to manufacture food processing equipment, such as mixers, conveyors, and storage tanks, as it is highly resistant to corrosion, easy to clean, and does not react with food substances. Stainless steel is also used for cutlery, cooking utensils, and appliances due to its durability, hygiene, and aesthetic appeal. Additionally, it is utilized in food preparation surfaces, countertops, and sinks, ensuring a safe and sanitary environment.

- Q: What are the advantages of using steel bars in construction?

- There are several advantages of using steel bars in construction. Firstly, steel bars provide excellent tensile strength, making them ideal for reinforcing concrete structures and enhancing their load-bearing capacity. Additionally, steel bars are highly durable and resistant to corrosion, ensuring the longevity and structural integrity of the construction. Moreover, steel bars are versatile and can be easily molded and shaped to fit various construction needs, making them suitable for a wide range of applications. Lastly, using steel bars in construction allows for efficient and cost-effective building processes, as they can be prefabricated off-site and easily transported to the construction site.

Send your message to us

Unequal Leg and Unequal Thickness Angle Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 PCS

- Supply Capability:

- 450000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords