Equal Angle Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 80000-100000MT/YEAR m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

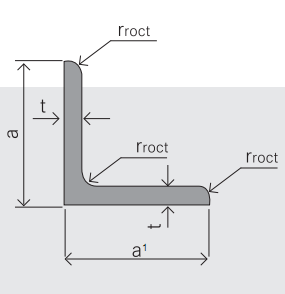

Specifications of Equal Angle Steel

1.Standards:GB,ASTM,BS,AISI,DIN,JIS

2.Length:6m,9m,12m

3.Material:GBQ235B,Q345BorEquivalent;ASTMA36;EN10025,S235JR,S355JR;JISG3192,SS400;SS540.

.

.

4.Sizes:

|

EQUAL ANGLES SIZES |

| ||

|

a(mm) |

a1(mm) |

thickness(mm) |

length |

|

25 |

25 |

2.5---3.0 |

6M/12M |

|

30 |

30 |

2.5---4.0 |

6M/12M |

|

38 |

38 |

2.5 |

6M/12M |

|

38 |

38 |

3.0---5.0 |

6M/12M |

|

40 |

40 |

3.0---6.0 |

6M/12M |

|

50 |

50 |

3 |

6M/12M |

|

50 |

50 |

3.7---6.0 |

6M/9M/12M |

|

60 |

60 |

5.0---6.0 |

6M/9M/12M |

|

63 |

63 |

6.0---8.0 |

6M/9M/12M |

|

65 |

65 |

5.0---8.0 |

6M/9M/12M |

|

70 |

70 |

6.0---7.0 |

6M/9M/12M |

|

75 |

75 |

5.0---10.0 |

6M/9M/12M |

|

80 |

80 |

6.0---10.0 |

6M/9M/12M |

|

90 |

90 |

6.0---10.0 |

6M/9M/12M |

|

100 |

100 |

6.0---12.0 |

6M/9M/12M |

|

120 |

120 |

8.0-12.0 |

6M/9M/12M |

|

125 |

125 |

8.0---12.0 |

6M/9M/12M |

|

130 |

130 |

9.0-12.0 |

6M/9M/12M |

|

140 |

140 |

10.0-16.0 |

6M/9M/12M |

|

150 |

150 |

10---15 |

6M/9M/12M |

|

160 |

160 |

10---16 |

6M/9M/12M |

|

180 |

180 |

12---18 |

6M/9M/12M |

|

200 |

200 |

14---20 |

6M/9M/12M |

5. Material details:

|

Alloy No |

Grade |

Element (%) |

|||||

|

C |

Mn |

S |

P |

Si |

|||

|

|

|

|

|

|

|

|

|

|

Q235 |

B |

0.12—0.20 |

0.3—0.7 |

≤0.045 |

≤0.045 |

≤0.3 |

|

|

|

|

|

|

|

|

|

|

|

Alloy No |

Grade |

Yielding strength point( Mpa) |

|||||

|

Thickness (mm) |

|||||||

|

≤16 |

>16--40 |

>40--60 |

>60--100 |

||||

|

≥ |

|||||||

|

|

|

|

|

|

|

||

|

Q235 |

B |

235 |

225 |

215 |

205 |

||

|

Alloy No |

Grade |

Tensile strength (Mpa) |

Elongation after fracture (%) |

||||

|

Thickness (mm) |

|||||||

|

|

≤16 |

>16--40 |

>40--60 |

>60--100 |

|||

|

≥ |

|||||||

|

|

|

|

|

|

|

|

|

|

Q235 |

B |

375--500 |

26 |

25 |

24 |

23 |

|

Usage & Applications of Equal Anlge Steel

Trusses;

Transmission towers;

Telecommunication towers;

Bracing for general structures;

Stiffeners in structural use.

Packaging & Delivery of Equal Angle Steel

1. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

2. With bundles and load in 20 feet/40 feet container, or by bulk cargo, also we could do as customer's request.

3. Marks:

Color mark: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: There will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

- Q:How are steel angles used in structural framing?

- Steel angles are commonly used in structural framing as they provide stability and support. They are often used to reinforce corners and joints, adding strength to the overall structure. Steel angles are also used as braces and supports in various construction projects, helping to distribute weight and prevent sagging or collapsing.

- Q:Can steel angles be used for wall bracing?

- Indeed, wall bracing can make use of steel angles. These angles are frequently employed in construction to offer structural support and reinforcement. Their primary function is to fortify walls and ensure the overall stability of the edifice. Owing to their robustness and longevity, steel angles are a highly suitable option for wall bracing purposes. Furthermore, their fabrication and installation are straightforward, rendering them a cost-efficient solution for wall bracing requirements.

- Q:Are steel angles suitable for architectural sculptures or installations?

- Yes, steel angles can be suitable for architectural sculptures or installations. Steel angles are versatile and durable, making them a popular choice for creating intricate and visually appealing structures. Their geometric shape allows for interesting angles and shapes to be formed, adding a unique aesthetic to architectural sculptures or installations. Additionally, steel angles can be easily welded or attached together, providing flexibility in design and construction. The strength and stability of steel angles also make them suitable for outdoor installations, as they can withstand various weather conditions. Overall, steel angles offer architects and artists a reliable and versatile material to create innovative and striking sculptures or installations.

- Q:Are steel angles suitable for use in high-rise buildings?

- Yes, steel angles are suitable for use in high-rise buildings. They are commonly used as structural members in high-rise construction due to their strength, durability, and ability to withstand heavy loads and forces. Steel angles provide excellent support and stability, making them a reliable choice for constructing the framework of high-rise buildings.

- Q:Can steel angles be used for structural support?

- Indeed, steel angles can serve as a means of providing structural support. Construction and engineering endeavors frequently employ steel angles in order to furnish structures with the necessary support and stability. Their application is particularly common in the construction of buildings, bridges, and various other forms of infrastructure. Steel angles possess strength and durability, rendering them suitable for bearing substantial loads and withstanding the forces of compression and tension. Furthermore, their L-shaped design facilitates effortless installation and connection to additional structural elements. By employing steel angles as beams, columns, braces, and other structural components, it is possible to endow a structure with both stability and strength.

- Q:Can steel angles be used for framing or supporting exterior façade elements?

- Yes, steel angles can be used for framing or supporting exterior façade elements. Steel angles provide structural support and stability, making them suitable for framing and supporting various components of an exterior façade, such as windows, doors, cladding, and signage. They offer strength, durability, and versatility, making them a popular choice in architectural and construction applications.

- Q:How do you calculate the strength of a steel angle?

- To calculate the strength of a steel angle, several factors need to be considered. The key parameters include the dimensions of the angle, the material properties of the steel, and the applied load or force. First, the dimensions of the angle must be determined. This includes measuring the length of both legs and the thickness of the angle. These measurements are essential for calculating the area moment of inertia, which is a crucial factor in determining the strength of the angle. Next, the material properties of the steel angle need to be known. This includes the yield strength, ultimate tensile strength, and the modulus of elasticity. These properties can be obtained from material specifications or testing. Once the dimensions and material properties are known, the strength of the steel angle can be calculated using various formulas and equations. One common approach is to calculate the section modulus, which is a measure of the resistance of the angle to bending. The section modulus can be calculated using the formula Z = (b × h^2)/6, where b is the thickness of the angle and h is the distance between the centroid of the angle to the outer edge. The strength of the angle can then be determined by comparing the applied load or force to the calculated section modulus. If the applied load is within the limits of the section modulus, the angle is considered to be structurally sound. However, if the applied load exceeds the section modulus, there is a risk of failure. It is important to note that the calculations for the strength of a steel angle are based on assumptions and ideal conditions. In practice, factors such as material imperfections, fabrication processes, and load distribution can affect the actual strength of the angle. Therefore, it is recommended to consult structural engineers or reference design codes to ensure accurate calculations and safe design.

- Q:Can steel angles be used for foundation supports?

- Yes, steel angles can be used for foundation supports. Steel angles provide structural support and stability, making them suitable for various construction applications, including foundation supports.

- Q:How are steel angles installed or fixed in place?

- Steel angles are commonly used in construction to provide structural support and reinforcement. They are installed or fixed in place using various methods, depending on the specific application and requirements of the project. One common method of installing steel angles is by welding. This involves permanently fusing the angles to the desired location using a welding machine. Welding provides a strong and durable connection, ensuring the angles stay in place even under heavy loads or vibrations. However, welding requires skilled labor and specialized equipment. Another method is bolting. Steel angles can be bolted to the supporting structure using bolts or screws. This method allows for easy installation and removal, making it suitable for situations where adjustments or modifications may be required. Bolting also offers flexibility in terms of repositioning or replacing the angles if needed. In some cases, steel angles are attached to the structure using adhesive bonding. This method involves applying a strong adhesive material between the angle and the supporting surface. Adhesive bonding is particularly useful when welding or bolting is not feasible or desired. However, it is important to ensure that the adhesive used is suitable for the specific application and can withstand the loads and environmental conditions. Additionally, steel angles can be installed using a combination of methods. For example, welding can be used to provide the primary attachment, while bolts or adhesive bonding can be used as secondary supports or reinforcements. It is crucial to consult with structural engineers or professionals to determine the most appropriate method for installing steel angles based on the specific project requirements, load conditions, and local building codes. Proper installation ensures the angles are securely fixed in place, providing the necessary strength and stability to the structure.

- Q:How do steel angles perform under lateral or wind loading conditions?

- Due to their strength and versatility, steel angles find widespread use in construction and engineering. They excel in handling lateral or wind loading conditions, demonstrating exceptional performance. When subjected to lateral forces acting horizontally and perpendicular to their axis, steel angles exhibit remarkable rigidity and resistance to bending. Consequently, they can withstand substantial lateral loads, making them perfect for applications such as bracing systems, support structures, and framing components that need to resist wind, seismic, or other lateral forces. Similarly, steel angles prove their excellence in wind loading conditions. As wind exerts a strong lateral force on structures, steel angles effectively counteract these forces. By securely fastening steel angles to the structure, stability is ensured, preventing wind-induced vibrations or even collapse. To enhance the performance of steel angles under lateral or wind loading conditions, proper design and installation are crucial. Engineers take into account factors like angle size and thickness, steel type and quality, as well as connection details. By carefully analyzing specific loading conditions and selecting the appropriate steel angles, engineers guarantee that structures remain stable and safe, even under extreme lateral or wind loads. In conclusion, steel angles are highly reliable and durable in handling lateral or wind loading conditions. Their robustness, coupled with their cost-effectiveness and ease of installation, makes them a favored choice in numerous construction and engineering projects.

1. Manufacturer Overview |

|

|---|---|

| Location | Tangshan, China |

| Year Established | 1996 |

| Annual Output Value | Above US$ 300 Million |

| Main Markets | Middle East; Korea; Southeast Aisa |

| Company Certifications | ISO 9001:2008; |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Tianjin; |

| Export Percentage | 70% - 80% |

| No.of Employees in Trade Department | 21-30 People |

| Language Spoken: | English; Chinese; |

| b)Factory Information | |

| Factory Size: | Above 900,000 square meters |

| No. of Production Lines | 3 |

| Contract Manufacturing | OEM Service Offered; |

| Product Price Range | Average |

Send your message to us

Equal Angle Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 80000-100000MT/YEAR m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords