Equal Steel Angle

- Loading Port:

- Tianjin Port China

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25MT m.t.

- Supply Capability:

- 600000MT/YEAR m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

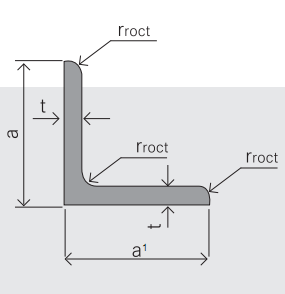

Specifications of Equal Steel Angle

1. Standards: GB,ASTM,BS,AISI,DIN,JIS

2. Length:6m,9m,12m

3. Material:Material: GB Q235B, Q345B or Equivalent; ASTM A36; EN 10025, S235JR, S355JR; JIS G3192,

SS400; SS540.

4. Sizes:

|

Sizes: 25mm-250mm | ||

|

a*t | ||

|

25*2.5-4.0 |

70*6.0-9.0 |

130*9.0-15 |

|

30*2.5-6.6 |

75*6.0-9.0 |

140*10-14 |

|

36*3.0-5.0 |

80*5.0-10 |

150*10-20 |

|

38*2.3-6.0 |

90*7.0-10 |

160*10-16 |

|

40*3.0-5.0 |

100*6.0-12 |

175*12-15 |

|

45*4.0-6.0 |

110*8.0-10 |

180*12-18 |

|

50*4.0-6.0 |

120*6.0-15 |

200*14-25 |

|

60*4.0-8.0 |

125*8.0-14 |

250*25 |

5. Material details:

|

Alloy No |

Grade |

Element (%) |

|||||

|

C |

Mn |

S |

P |

Si |

|||

|

|

|

|

|

|

|

|

|

|

Q235 |

B |

0.12—0.20 |

0.3—0.7 |

≤0.045 |

≤0.045 |

≤0.3 |

|

|

|

|

|

|

|

|

|

|

|

Alloy No |

Grade |

Yielding strength point( Mpa) |

|||||

|

Thickness (mm) |

|||||||

|

≤16 |

>16--40 |

>40--60 |

>60--100 |

||||

|

≥ |

|||||||

|

|

|

|

|

|

|

||

|

Q235 |

B |

235 |

225 |

215 |

205 |

||

|

Alloy No |

Grade |

Tensile strength (Mpa) |

Elongation after fracture (%) |

||||

|

Thickness (mm) |

|||||||

|

|

≤16 |

>16--40 |

>40--60 |

>60--100 |

|||

|

≥ |

|||||||

|

|

|

|

|

|

|

|

|

|

Q235 |

B |

375--500 |

26 |

25 |

24 |

23 |

|

Usage & Applications of Equal Steel Angle

Trusses;

Transmission towers;

Telecommunication towers;

Bracing for general structures;

Stiffeners in structural use.

Packaging & Delivery of Equal Steel Angle

1.Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

2.With bundles and load in 20 feet/40 feet container, or by bulk cargo, also we could do as customer's request.

3. Marks:

Color mark: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: There will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

- Q: What are the considerations for selecting the appropriate steel angle finish?

- When selecting the appropriate steel angle finish, there are several considerations that need to be taken into account. One of the primary considerations is the intended use or application of the steel angle. Different finishes offer varying levels of corrosion resistance, which is particularly important in environments where the steel angle will be exposed to moisture or chemicals. For example, a hot-dip galvanized finish provides excellent corrosion resistance and is often preferred for outdoor applications or in environments with high humidity levels. On the other hand, a plain steel finish may be suitable for indoor applications where corrosion resistance is not a major concern. Another consideration is the desired aesthetic appearance. Steel angles can be finished in various ways to achieve different looks. For instance, a mill finish provides a raw, industrial appearance, while a powder coat finish offers a wide range of color options and a more polished look. The choice of finish will depend on the desired aesthetic effect and the overall design of the project. Furthermore, the level of durability required should also be taken into consideration. Some finishes, such as a zinc plating or a stainless steel finish, provide enhanced durability and resistance to wear and tear, making them suitable for heavy-duty applications or areas with high traffic. Conversely, a painted finish may be more prone to chipping or scratching, making it less suitable for applications that require long-term durability. Lastly, cost is an important factor to consider. Different finishes have varying costs associated with them, so it is essential to balance the desired finish with the available budget. It is worth noting that while certain finishes may have a higher upfront cost, they may provide long-term cost savings by reducing maintenance or replacement needs. In conclusion, the selection of the appropriate steel angle finish depends on factors such as corrosion resistance, aesthetic appearance, durability requirements, and budget considerations. By carefully evaluating these considerations, one can choose the most suitable finish that meets both functional and aesthetic needs.

- Q: Can steel angles be used in the construction of parking garages?

- Yes, steel angles can be used in the construction of parking garages. Steel angles are commonly used in construction for their strength, durability, and versatility. They can be used in various structural applications, including the construction of parking garages. Steel angles can be used to provide support and reinforcement for structural elements such as beams and columns, as well as for framing and bracing. They are often used to create the framework for parking garage floors and walls, providing stability and strength to the structure. Additionally, steel angles can be easily fabricated and customized to meet the specific design and engineering requirements of a parking garage. Overall, steel angles are a popular choice in the construction of parking garages due to their ability to withstand heavy loads, resist corrosion, and provide long-lasting performance.

- Q: Can steel angles be used for handrail supports?

- Yes, steel angles can be used for handrail supports. Steel angles are commonly used as a structural element in construction and can provide sufficient strength and stability to support handrails.

- Q: Are there any environmental concerns associated with steel angles?

- Steel angles are associated with various environmental concerns. The production process involves extracting iron ore, mining coal for coke production, and emitting greenhouse gases during steelmaking. These activities contribute to deforestation, air pollution, and climate change. Furthermore, disposing of steel angles at the end of their life cycle can be problematic. Steel is not biodegradable and can take hundreds of years to decompose in landfills. Improper disposal can contaminate soil and water, posing risks to ecosystems and human health. Moreover, transporting steel angles from production facilities to construction sites can lead to carbon emissions and air pollution. The energy needed for transportation increases the overall environmental impact. To address these concerns, several strategies can be implemented. Firstly, using recycled steel instead of virgin steel significantly reduces the environmental footprint. Additionally, employing energy-efficient technologies in the production process can minimize greenhouse gas emissions. Lastly, responsibly disposing and recycling steel angles at the end of their life cycle helps reduce the environmental impact.

- Q: What are the typical lead times for steel angle orders?

- Lead times for steel angle orders can vary based on a variety of factors. Standard steel angles that are readily available in stock typically have lead times ranging from a few days to a week. This is because steel suppliers commonly produce and keep these standard sizes in inventory. However, if the steel angle order requires specific dimensions, finishes, or special requirements, the lead times may be longer. Custom or non-standard steel angles may need to be fabricated or sourced from mills, which can add extra time to the order fulfillment process. Depending on the complexity of the specifications and the availability of materials, lead times for these orders can range from a few weeks to several months. It is important to keep in mind that external factors like market demand, production schedules, and transportation logistics can also influence lead times. Therefore, it is advisable to communicate with the steel supplier or manufacturer to obtain an accurate estimation of lead times for specific steel angle orders.

- Q: Can steel angles be used in mining or offshore applications?

- Mining or offshore applications can utilize steel angles. These industries often rely on steel angles for their robustness, longevity, and adaptability. Steel angles are employed for an array of functions, including framing, support, reinforcement, and bracing in mining structures and offshore platforms. Moreover, steel angles possess the capability to endure harsh environments, adverse weather conditions, and corrosive elements frequently encountered in mining or offshore operations. Their capacity to offer structural stability and withstand impact and vibrations renders them well-suited for these applications. All in all, steel angles present a dependable and economically viable option for the mining and offshore sectors.

- Q: What are the different types of surface finishes available for steel angles?

- There are several different types of surface finishes available for steel angles, each providing unique characteristics and benefits. 1. Mill Finish: This is the most basic and common type of surface finish for steel angles. It is essentially the raw, untreated surface of the steel, which may have some imperfections and roughness. Mill finish is often used for structural applications where aesthetics are not a priority. 2. Hot-Dip Galvanized: This surface finish involves immersing the steel angle in a bath of molten zinc, creating a protective coating that prevents corrosion. Hot-dip galvanized steel angles are highly resistant to rust and can be used in outdoor or corrosive environments. 3. Powder Coated: Powder coating is a process where a dry powder is electrostatically applied to the steel angle and then cured under heat. This creates a durable and attractive finish that provides excellent resistance to chipping, scratching, and fading. Powder coated steel angles are commonly used in architectural and decorative applications. 4. Painted: Steel angles can also be painted with various types of paint, such as epoxy, enamel, or acrylic. Paint provides a protective layer and can enhance the appearance of the steel angle. However, painted surfaces may be more susceptible to chipping and require periodic maintenance. 5. Stainless Steel: Stainless steel angles have a naturally smooth and polished surface due to their composition. They are highly resistant to corrosion and staining, making them suitable for applications in industries such as food processing, pharmaceuticals, and marine environments. 6. Shot Blasting: Shot blasting is a surface treatment process where steel angles are bombarded with small metallic or non-metallic particles at high velocity. This removes any rust, scale, or contaminants from the surface, resulting in a clean and roughened finish. Shot blasting prepares the steel angle for further coating or painting. These are just a few examples of the different types of surface finishes available for steel angles. The choice of finish depends on the specific requirements of the application, including factors such as corrosion resistance, aesthetics, durability, and cost.

- Q: Can steel angles be galvanized or coated for corrosion resistance?

- Steel angles have the capability to undergo galvanization or coating in order to achieve corrosion resistance. Galvanization is a widely utilized technique for safeguarding steel against corrosion, wherein a layer of zinc is applied to the surface. This method establishes a barrier between the steel and its surroundings, effectively preventing the formation of rust. Alternatively, steel angles can be coated with materials that possess corrosion-resistant properties, such as epoxy or powder coatings. These coatings serve as a protective shield, preventing moisture and other corrosive substances from reaching the steel surface. By employing galvanization or coatings, the lifespan of steel angles can be significantly extended, allowing them to maintain their structural integrity even in highly corrosive environments.

- Q: What are the different types of steel angles used in architectural façade systems?

- There are several different types of steel angles used in architectural façade systems, including equal leg angles, unequal leg angles, L-shaped angles, and custom fabricated angles. These angles are used to provide structural support, create visual interest, and enhance the overall design of the building's exterior.

- Q: What is the maximum length of a steel angle?

- The maximum length of a steel angle typically depends on the manufacturing capabilities and transportation limitations. However, it is common for steel angles to be produced in lengths up to 40 feet or 12 meters.

1. Manufacturer Overview

| Location | Tangshan, China |

| Year Established | 1996 |

| Annual Output Value | Above US$ 300 Million |

| Main Markets | Middle East; Korea; Southeast Aisa |

| Company Certifications | ISO 9001:2008; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; |

| Export Percentage | 70% - 80% |

| No.of Employees in Trade Department | 21-30 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 900,000 square meters |

| No. of Production Lines | 3 |

| Contract Manufacturing | OEM Service Offered; |

| Product Price Range | Average |

Send your message to us

Equal Steel Angle

- Loading Port:

- Tianjin Port China

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25MT m.t.

- Supply Capability:

- 600000MT/YEAR m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords