JIS Equal Angle Steel Angles

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of JIS Equal Angle

1.Standards:GB,ASTM,BS,AISI,DIN,JIS

2.Length:6m,9m,12m

3.Material:GBQ235B,Q345BorEquivalent;ASTMA36;EN10025,S235JR,S355JR;JISG3192,SS400;SS540.

4. Payment terms:

1).100% irrevocable L/C at sight.

2).30% T/T prepaid and the balance against the copy of B/L.

3).30% T/T prepaid and the balance against L/C

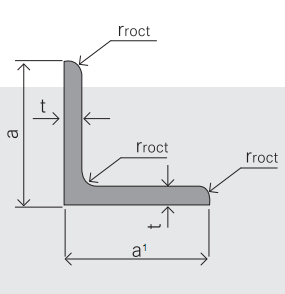

5.Sizes:

EQUAL ANGLES SIZES |

| ||

a(mm) | a1(mm) | thickness(mm) | length |

25 | 25 | 2.5---3.0 | 6M/12M |

30 | 30 | 2.5---4.0 | 6M/12M |

38 | 38 | 2.5 | 6M/12M |

38 | 38 | 3.0---5.0 | 6M/12M |

40 | 40 | 3.0---6.0 | 6M/12M |

50 | 50 | 3 | 6M/12M |

50 | 50 | 3.7---6.0 | 6M/9M/12M |

60 | 60 | 5.0---6.0 | 6M/9M/12M |

63 | 63 | 6.0---8.0 | 6M/9M/12M |

65 | 65 | 5.0---8.0 | 6M/9M/12M |

70 | 70 | 6.0---7.0 | 6M/9M/12M |

75 | 75 | 5.0---10.0 | 6M/9M/12M |

80 | 80 | 6.0---10.0 | 6M/9M/12M |

90 | 90 | 6.0---10.0 | 6M/9M/12M |

100 | 100 | 6.0---12.0 | 6M/9M/12M |

120 | 120 | 8.0-12.0 | 6M/9M/12M |

125 | 125 | 8.0---12.0 | 6M/9M/12M |

130 | 130 | 9.0-12.0 | 6M/9M/12M |

140 | 140 | 10.0-16.0 | 6M/9M/12M |

150 | 150 | 10---15 | 6M/9M/12M |

160 | 160 | 10---16 | 6M/9M/12M |

180 | 180 | 12---18 | 6M/9M/12M |

200 | 200 | 14---20 | 6M/9M/12M |

6. Material details:

Grade | Yield Strength,N/mm² | Extension Strength N/mm² | |||

Thickness of Steel,mm | |||||

≦16 | >16-≦40 | >40-≦100 | >100 | ||

SS330 | ≧205 | ≧195 | ≧175 | ≧165 | 330-430 |

SS400 | ≧245 | ≧235 | ≧215 | ≧205 | 400-510 |

SS490 | ≧285 | ≧275 | ≧255 | ≧245 | 490-610 |

SS540 | ≧400 | ≧390 | - | - | ≧540 |

Usage & Applications of JIS Equal Angle

Trusses;

Transmission towers;

Telecommunication towers;

Bracing for general structures;

Stiffeners in structural use.

Packaging & Delivery of JIS Equal Angle

1. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

2. With bundles and load in 20 feet/40 feet container, or by bulk cargo, also we could do as customer's request.

3. Marks:

Color mark: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: There will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

- Q: Can steel angles be customized or fabricated to specific requirements?

- Yes, steel angles can be customized or fabricated to specific requirements. Steel angles are versatile and can be easily modified to meet different specifications and applications. Fabrication processes such as cutting, drilling, welding, and bending can be used to customize steel angles to the desired shape, size, and dimensions. This allows for the creation of steel angles with specific lengths, thicknesses, and angles to meet the unique requirements of different construction or engineering projects. Customized steel angles can be used in various applications, including structural framing, supports, brackets, reinforcements, and architectural designs. Overall, steel angles offer flexibility in customization and fabrication, making them suitable for a wide range of construction and industrial needs.

- Q: Are there any industry standards or certifications for steel angles?

- Steel angles have industry standards and certifications. The main standard for steel angles is the ASTM standard, specifically the ASTM A36 specification. This specification outlines the necessary chemical composition, mechanical properties, and dimensional tolerances for structural steel angles. Aside from ASTM, other organizations like AISC and SJI also provide guidelines and standards for steel angles used in construction and structural engineering. These standards guarantee that steel angles meet specific requirements in terms of quality, strength, and performance. Moreover, certifications like ISO 9001:2015 and ISO 14001:2015 are widely recognized in the steel industry. These certifications indicate that a manufacturer has implemented a quality management system and complies with environmental management standards. Adhering to these industry standards and certifications is crucial for manufacturers, suppliers, and construction professionals. It ensures the dependability and safety of steel angles in various applications.

- Q: What are the different welding methods used for steel angles?

- There are several different welding methods that can be used for steel angles. The choice of method depends on various factors including the thickness of the steel, the type of joint, and the desired outcome. Here are some of the commonly used welding methods for steel angles: 1. Shielded Metal Arc Welding (SMAW): Also known as stick welding, SMAW uses a consumable electrode coated in flux. The electrode is manually fed into the joint, and the flux creates a protective shield around the weld pool. SMAW is versatile and can be used for various joint configurations and thicknesses. 2. Gas Metal Arc Welding (GMAW): Commonly referred to as MIG (Metal Inert Gas) or MAG (Metal Active Gas) welding, GMAW uses a wire electrode that is continuously fed through a welding gun. The electrode melts and joins the steel angles together, while a shielding gas (either inert or active) protects the weld pool. GMAW is fast and suitable for thin to medium thickness steel angles. 3. Flux-Cored Arc Welding (FCAW): Similar to GMAW, FCAW uses a continuously fed wire electrode. However, the electrode is filled with flux, eliminating the need for an external shielding gas. FCAW is versatile, easy to use, and can be employed in various positions. It is commonly used for thicker steel angles and in outdoor applications where wind might affect gas shielding. 4. Gas Tungsten Arc Welding (GTAW): Also known as TIG (Tungsten Inert Gas) welding, GTAW uses a non-consumable tungsten electrode to create an arc. A separate filler metal is manually added to the joint, while a shielding gas protects the weld pool. GTAW produces high-quality, precise welds and is commonly used for thinner steel angles or when aesthetics are important. 5. Submerged Arc Welding (SAW): This method involves feeding a continuously fed wire electrode into the joint while simultaneously covering the weld area with a layer of granular flux. The flux acts as a protective medium and prevents atmospheric contamination. SAW is commonly used for thicker steel angles and in applications where high deposition rates are required. These are just a few of the welding methods commonly used for steel angles. Each method has its advantages and limitations, and the choice of method should be based on the specific requirements of the project. It is important to consult with a qualified welding professional to determine the most suitable method for a particular application.

- Q: What are the design considerations when using steel angles?

- When incorporating steel angles into design, there are several important factors to keep in mind. Firstly, the load-bearing capacity of the steel angles must be thoroughly evaluated. The anticipated loads and stresses that the structure will endure should dictate the selection of the appropriate size, thickness, and configuration of the angles. Another factor to consider is the structural integrity of the connections between the steel angles and other design elements. The connections must be designed to provide sufficient strength and stiffness, while also accommodating any potential movement or deformation of the angles. The potential for corrosion when using steel angles should also be taken into account. To prevent rust and deterioration, it is essential to apply suitable protective coatings or treatments, especially in outdoor or high-moisture environments. Aesthetics and visual appeal are also significant considerations in design. The shape, finish, and overall appearance of the steel angles should align with the desired aesthetic of the project, whether it is a modern, industrial look or a more traditional and ornamental design. Finally, cost and availability should be considered when incorporating steel angles. The project's overall budget should be weighed against the cost of materials, fabrication, and installation. Additionally, it is important to consider the availability of the desired sizes and configurations of steel angles to ensure a smooth and timely construction process. By carefully considering these design factors, designers can effectively integrate steel angles into their projects, guaranteeing structural integrity, aesthetic appeal, and cost-effectiveness.

- Q: What are the different types of steel angles connections for joists?

- Joists commonly employ several types of steel angle connections. These options include: 1. Welded Connection: The simplest and most prevalent connection involves directly welding the steel angles to the joists. This method provides a sturdy and inflexible connection, albeit requiring skilled labor and additional welding time. 2. Bolted Connection: This connection involves fastening the steel angles to the joists using bolts or screws. It allows for easier installation and disassembly if necessary. However, it may not be as robust as a welded connection and may necessitate periodic bolt tightening. 3. Gusset Plate Connection: A flat steel plate known as a gusset plate connects the steel angles to the joists. Typically, this plate is secured by welding or bolting to both the angles and the joists, enhancing the connection's strength and stability. 4. Clip Angle Connection: L-shaped brackets called clip angles attach to the joists and steel angles using bolts or screws. This method offers a straightforward and efficient means of connecting angles to the joists, with the added benefit of easy adjustment or replacement. 5. Shear Plate Connection: This connection type employs a thick steel plate with holes, known as a shear plate, to link the steel angles to the joists. Like the gusset plate connection, the shear plate is usually welded or bolted to both the angles and the joists, ensuring a robust and secure connection. The selection of a particular steel angle connection method depends on factors such as load requirements, installation ease, and cost considerations, as each option presents its own advantages and disadvantages.

- Q: How do steel angles contribute to the overall earthquake resistance of a structure?

- Steel angles contribute to the overall earthquake resistance of a structure in several ways. First and foremost, steel angles are commonly used as reinforcement elements in the construction industry. When properly installed and anchored, they can help increase the overall strength and stability of a structure, making it more resistant to the lateral forces generated during an earthquake. Steel angles are often used to create moment-resisting frames, which are designed to absorb and distribute the seismic energy throughout the structure. These frames, made up of interconnected steel angles, provide a robust system that can effectively resist the horizontal forces exerted by an earthquake. By distributing the seismic load, steel angles help prevent concentrated stress points and potential failure of the structure. Moreover, steel angles can be strategically placed at key locations, such as corners, junctions, and openings, to enhance the overall stiffness and rigidity of the structure. This increased stiffness helps reduce the building's response to seismic vibrations and prevents excessive deformation, which could lead to structural damage. Additionally, steel angles can be used to create diagonal bracing systems, which are essential for mitigating the effects of seismic forces. These systems consist of interconnected steel angles diagonally placed within the structure, forming a network that improves the building's ability to withstand lateral loads. Diagonal bracing effectively dissipates earthquake energy and redirects it away from critical components, thus enhancing the structure's overall earthquake resistance. In summary, steel angles play a crucial role in enhancing the earthquake resistance of a structure. They provide reinforcement, create moment-resisting frames, increase stiffness, and enable the installation of diagonal bracing systems, all of which contribute to the structural integrity and resilience of a building during seismic events.

- Q: How do you determine the required number of fasteners for a steel angle connection?

- To determine the required number of fasteners for a steel angle connection, several factors need to be considered. These include the load being applied, the size and thickness of the angle, the type and strength of the fasteners being used, and any applicable building codes or engineering standards. Typically, calculations or guidelines provided by structural engineers or industry standards are used to determine the minimum number and spacing of fasteners needed to ensure the connection is strong and safe.

- Q: What are the different types of steel angle connections used in seismic design?

- In seismic design, there are several types of steel angle connections commonly used. These connections are specifically designed to withstand the forces and movements experienced during seismic events. Some of the different types of steel angle connections used in seismic design include: 1. Bolted Flange Plate Connection: This type of connection involves bolting a steel plate to the flanges of two angle sections. It provides good resistance against lateral and vertical forces and can accommodate rotational movements. 2. Welded Flange Plate Connection: Similar to the bolted flange plate connection, this connection involves welding a steel plate to the flanges of two angle sections. It offers high strength and stiffness, but it is less ductile compared to the bolted version. 3. Extended Single Plate Connection: This connection is created by extending a single plate beyond the flanges of two angle sections and then welding it to both the flanges. It provides good resistance against lateral and vertical forces and can accommodate some degree of rotation. 4. Double Angle Connection: In this connection, two angle sections are connected together using bolts or welds. It offers high strength and stiffness and can resist lateral and vertical forces effectively. 5. Diagonal Brace Connection: This type of connection involves connecting diagonal braces to the flanges of two angle sections. It provides enhanced resistance against lateral forces and can effectively control building sway during seismic events. 6. Gusset Plate Connection: This connection involves using a gusset plate to connect two or more angle sections together. It provides good strength and stiffness and can resist lateral and vertical forces effectively. Each of these steel angle connections has its own advantages and disadvantages, and the choice of which connection to use depends on factors such as the structural design requirements, loadings, and the level of seismic activity in the region. It is important to carefully consider these factors and consult with structural engineers to ensure the appropriate connection type is used for a seismic design project.

- Q: How do you determine the shear capacity of a steel angle?

- In order to establish the shear capacity of a steel angle, various factors must be taken into account. The shear capacity signifies the maximum load that the angle can endure without experiencing shear failure. The initial step in determining the shear capacity involves identifying the characteristics of the steel angle, such as the grade of the material and its dimensions. The strength properties of the steel, which are crucial for calculating the shear capacity, are determined by its grade. The calculations are also significantly influenced by the dimensions of the angle, including its length, width, and thickness. Subsequently, it becomes necessary to ascertain the critical shear area of the angle. This area represents the section of the angle that will encounter the highest shear stress during loading. By considering the location of the applied load and the geometry of the angle, the critical shear area can be calculated. Once the critical shear area is determined, the subsequent step is to compute the shear stress exerted on this area. The shear stress is calculated by dividing the applied load by the area. It is crucial to ensure that the shear stress does not surpass the allowable shear stress for the specific grade of steel being utilized. The allowable shear stress is typically provided by design codes or standards. Finally, the shear capacity of the steel angle can be calculated by multiplying the shear stress by the critical shear area. This calculation yields the maximum load that the angle can withstand without experiencing shear failure. It is important to bear in mind that the shear capacity of a steel angle can be influenced by additional factors such as the presence of holes or welds, which can weaken the structure. In such cases, further calculations or considerations may be necessary. Overall, the process of determining the shear capacity of a steel angle encompasses considering the properties of the steel, calculating the critical shear area, determining the shear stress, and ensuring that it does not exceed the allowable shear stress for the material grade.

- Q: Are steel angles corrosion resistant?

- Steel angles are generally not corrosion resistant unless they are specifically designed and treated to be so. Regular steel angles are made from carbon steel, which is susceptible to corrosion when exposed to moisture, oxygen, and other corrosive elements. However, there are stainless steel angles available that have a higher resistance to corrosion due to the addition of chromium and other alloying elements. These stainless steel angles are commonly used in environments where corrosion is a concern, such as marine or industrial applications. It is important to consider the specific type and grade of steel angle being used to determine its corrosion resistance capabilities.

1. Manufacturer Overview

| Location | Hebei, China |

| Year Established | 2003 |

| Annual Output Value | Above US$ 500 Million |

| Main Markets | Southeast Asia; middle east; South Korea; Africa |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 30%-45% |

| No.of Employees in Trade Department | 11-20 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 10,000 square meters |

| No. of Production Lines | 2 |

| Contract Manufacturing | OEM service offered |

| Product Price Range | high; average |

Send your message to us

JIS Equal Angle Steel Angles

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords