GB Equal Structural Angle Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000T/Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

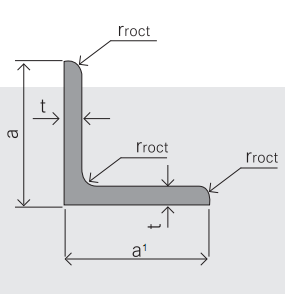

Specifications of GB Equal Structural Angle

1. Invoicing on theoretical weight or actual weight as customer request

2. Length: 6m, 9m, 12m

3. Material:Material: GB Q235B, Q345B or Equivalent; ASTM A36; EN 10025, S235JR, S355JR; JIS G3192, SS400;

SS540.

4.Sizes:

|

Sizes: 25mm-250mm | ||

|

a*t | ||

|

25*2.5-4.0 |

70*6.0-9.0 |

130*9.0-15 |

|

30*2.5-6.6 |

75*6.0-9.0 |

140*10-14 |

|

36*3.0-5.0 |

80*5.0-10 |

150*10-20 |

|

38*2.3-6.0 |

90*7.0-10 |

160*10-16 |

|

40*3.0-5.0 |

100*6.0-12 |

175*12-15 |

|

45*4.0-6.0 |

110*8.0-10 |

180*12-18 |

|

50*4.0-6.0 |

120*6.0-15 |

200*14-25 |

|

60*4.0-8.0 |

125*8.0-14 |

250*25 |

5. Material details:

|

Alloy No |

Grade |

Element (%) |

|||||

|

C |

Mn |

S |

P |

Si |

|||

|

|

|

|

|

|

|

|

|

|

Q235 |

B |

0.12—0.20 |

0.3—0.7 |

≤0.045 |

≤0.045 |

≤0.3 |

|

|

|

|

|

|

|

|

|

|

|

Alloy No |

Grade |

Yielding strength point( Mpa) |

|||||

|

Thickness (mm) |

|||||||

|

≤16 |

>16--40 |

>40--60 |

>60--100 |

||||

|

≥ |

|||||||

|

|

|

|

|

|

|

||

|

Q235 |

B |

235 |

225 |

215 |

205 |

||

|

Alloy No |

Grade |

Tensile strength (Mpa) |

Elongation after fracture (%) |

||||

|

Thickness (mm) |

|||||||

|

|

≤16 |

>16--40 |

>40--60 |

>60--100 |

|||

|

≥ |

|||||||

|

|

|

|

|

|

|

|

|

|

Q235 |

B |

375--500 |

26 |

25 |

24 |

23 |

|

Usage & Applications of GB Equal Structural Angle

According to the needs of different structures, Angle can compose to different force support component, and also can be the connections between components. It is widely used in various building structures and engineering structures such as roof beams, bridges, transmission towers, hoisting machinery and transport machinery, ships, industrial furnaces, reaction tower, container frame and warehouse etc.

Packaging & Delivery of GB Equal Structural Angle

1. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

2. With bundles and load in 20 feet/40 feet container, or by bulk cargo, also we could do as customer's request.

3. Marks:

Color mark: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: There will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

- Q: What is the meaning of the number of angle steel

- Angle called angle, the steel strip is perpendicular to each other on both sides into the corner. The angle iron can be made up of different force components according to the different structure, and can also be used as the connecting piece between the components.

- Q: Can steel angles be used in HVAC ductwork installations?

- Yes, steel angles can be used in HVAC ductwork installations. Steel angles are commonly used to provide support and stability to ductwork systems. They are typically used as brackets or supports to secure the ducts in place and prevent them from sagging or collapsing under the weight of the air conditioning or heating equipment. Steel angles are strong and durable, making them suitable for withstanding the forces and vibrations that occur in HVAC systems. Additionally, steel angles can be easily welded or bolted together, allowing for a secure and stable installation. Overall, steel angles are a reliable and commonly used component in HVAC ductwork installations.

- Q: How are steel angles used in construction?

- Steel angles are commonly used in construction to provide structural support and stability. They are often used as braces, struts, or beams to reinforce the framework of buildings, bridges, and other structures. Steel angles can also be used as corner supports, especially in the construction of walls and ceilings. Their versatility and strength make them an essential component in various construction applications.

- Q: Are steel angles suitable for architectural sculptures or installations?

- Yes, steel angles can be suitable for architectural sculptures or installations. Steel angles are versatile and durable, making them a popular choice for creating intricate and visually appealing structures. Their geometric shape allows for interesting angles and shapes to be formed, adding a unique aesthetic to architectural sculptures or installations. Additionally, steel angles can be easily welded or attached together, providing flexibility in design and construction. The strength and stability of steel angles also make them suitable for outdoor installations, as they can withstand various weather conditions. Overall, steel angles offer architects and artists a reliable and versatile material to create innovative and striking sculptures or installations.

- Q: What are the different types of corrosion protection coatings for steel angles?

- For steel angles, there exists a variety of corrosion protection coatings that serve different purposes in safeguarding against corrosion. 1. Paint Coatings: Paint coatings are frequently employed for corrosion protection of steel angles. Acting as a barrier, they shield the steel surface from corrosive elements present in the surroundings. These coatings are typically applied in multiple layers and can be tailored to meet specific needs, such as resistance to chemicals or UV radiation. 2. Galvanizing: Another extensively used method for corrosion protection in steel angles is galvanizing. This process entails the application of a zinc layer to the steel surface through hot-dip galvanizing. By acting as a sacrificial anode, this coating provides excellent corrosion protection, sacrificing itself before the steel. Galvanized steel angles are commonly utilized in outdoor settings where exposure to moisture and harsh weather conditions is expected. 3. Powder Coatings: Powder coatings, which are applied as a dry powder and cured with heat, offer a durable and corrosion-resistant finish for steel angles. These coatings can be customized in terms of color, texture, and thickness, ensuring both aesthetic appeal and enhanced protection against corrosion. 4. Epoxy Coatings: Industrial applications often require the use of epoxy coatings when steel angles may be exposed to harsh chemicals or abrasive environments. These coatings form a robust and protective layer that resists corrosion, chemicals, solvents, and abrasion. They can be applied as a single layer or combined with other coatings for added protection. 5. Organic Coatings: In architectural applications where corrosion protection is necessary while maintaining an attractive appearance, organic coatings such as polyurethane or acrylic coatings are commonly used for steel angles. These coatings offer good resistance to weathering, UV radiation, and corrosion, ensuring the longevity of the steel angles. When selecting a corrosion protection coating for steel angles, it is crucial to consider the specific application, environmental conditions, and budget constraints. Seeking advice from corrosion specialists or coating suppliers can help determine the most suitable coating for the intended use.

- Q: What are the design considerations for incorporating steel angles into a structure?

- When incorporating steel angles into a structure, several design considerations need to be taken into account. First and foremost, the load-bearing capacity of the steel angles must be carefully assessed to ensure they can support the intended loads. The dimensions and thickness of the angles should be determined based on the structural requirements and anticipated stress levels. Additionally, the connection details between the steel angles and other structural elements need to be carefully designed to ensure they provide sufficient strength and rigidity. Considerations should include the type of fasteners, welding techniques, and any additional reinforcement required to achieve the desired structural integrity. Furthermore, factors such as corrosion protection, fire resistance, and durability should also be considered during the design process. Appropriate measures should be taken to prevent rust and corrosion on the steel angles, such as applying protective coatings or using stainless steel. Fire-resistant coatings or fireproofing materials may also be necessary, depending on the building's fire safety requirements. Lastly, aesthetics and architectural considerations may come into play when incorporating steel angles into a structure. The design should take into account the desired visual appearance, whether the angles will be exposed or concealed, and how they will integrate with the overall architectural style. In conclusion, the design considerations for incorporating steel angles into a structure involve assessing load-bearing capacity, connection details, corrosion protection, fire resistance, durability, and aesthetic integration.

- Q: Can steel angles be used for framing or supporting partitions?

- Indeed, framing or supporting partitions can be achieved through the utilization of steel angles. In construction, steel angles are frequently employed due to their remarkable strength and durability. They possess the ability to offer structural support and ensure stability for walls and partitions. Typically, steel angles are fastened to both the floor and ceiling, enabling the creation of a framework for the partition. Moreover, they can serve to reinforce preexisting walls or structures. Furthermore, steel angles possess the advantage of being easily cut and welded to correspond to precise dimensions, rendering them highly versatile for framing or supporting partitions.

- Q: What is the typical thickness tolerance for steel angles?

- The typical thickness tolerance for steel angles can vary depending on the specific manufacturing standards and requirements. In general, the thickness tolerance for steel angles is typically within a range of +/- 0.005 to 0.010 inches (0.13 to 0.25 mm). However, it is important to note that this tolerance can also be influenced by the size and dimensions of the angle. Larger and thicker steel angles may have slightly looser tolerances compared to smaller and thinner angles. It is always recommended to consult the relevant industry standards or specifications to determine the specific thickness tolerance for a particular steel angle.

- Q: Can steel angles be used as bracing elements in buildings?

- Yes, steel angles can be used as bracing elements in buildings. Steel angles provide structural support and stability, making them suitable for use as bracing elements to resist lateral forces and improve the overall strength of a building.

- Q: What are the alternatives to steel angles in construction?

- Construction offers various alternatives to steel angles, each with its own advantages and disadvantages depending on the specific application. 1. Aluminum angles provide a lightweight and corrosion-resistant option for outdoor construction projects. They are easily machinable and have good electrical conductivity. However, they may not possess the same strength and load-bearing capacity as steel angles, limiting their suitability for heavy-duty structural applications. 2. Fiberglass angles, on the other hand, offer a lightweight and non-conductive solution that is highly resistant to corrosion and chemical damage. They are commonly used in industries exposed to harsh environments. However, their strength may be inferior to that of steel angles, necessitating additional reinforcement for heavy loads. 3. Carbon fiber angles are known for their lightweight and high-strength properties, making them ideal for weight reduction in critical applications like aerospace and automotive industries. However, they tend to be more expensive than steel angles and require specialized manufacturing techniques. 4. Wood angles, made from hardwood or engineered wood products, present a traditional and cost-effective alternative to steel angles. They are readily available and easy to work with, often used in residential and light commercial construction projects. However, their strength and durability may not match that of steel angles, and they may be prone to warping, cracking, or rotting over time. When selecting an alternative to steel angles, it is crucial to consider the specific requirements of the construction project, including load-bearing capacity, environmental conditions, and budget. Consulting with a structural engineer or construction professional can help determine the most suitable option for each scenario.

1. Manufacturer Overview

| Location | Tangshan, China |

| Year Established | 1996 |

| Annual Output Value | Above US$ 300 Million |

| Main Markets | Middle East; Korea; Southeast Aisa |

| Company Certifications | ISO 9001:2008; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; |

| Export Percentage | 70% - 80% |

| No.of Employees in Trade Department | 21-30 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 900,000 square meters |

| No. of Production Lines | 3 |

| Contract Manufacturing | OEM Service Offered; |

| Product Price Range | Average |

Send your message to us

GB Equal Structural Angle Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000T/Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords