Equal Angle steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

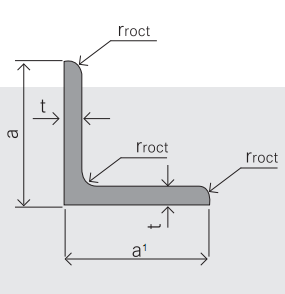

Specifications of Equal Angle

1. Standards: GB,ASTM,BS,AISI,DIN,JIS

2. Length:6m,9m,12m

3. Material:Material: GB Q235B, Q345B or Equivalent; ASTM A36; EN 10025, S235JR, S355JR; JIS G3192, SS400;

SS540.

4. Sizes:

Sizes: 25mm-250mm | ||

a*t | ||

25*2.5-4.0 | 70*6.0-9.0 | 130*9.0-15 |

30*2.5-6.6 | 75*6.0-9.0 | 140*10-14 |

36*3.0-5.0 | 80*5.0-10 | 150*10-20 |

38*2.3-6.0 | 90*7.0-10 | 160*10-16 |

40*3.0-5.0 | 100*6.0-12 | 175*12-15 |

45*4.0-6.0 | 110*8.0-10 | 180*12-18 |

50*4.0-6.0 | 120*6.0-15 | 200*14-25 |

60*4.0-8.0 | 125*8.0-14 | 250*25 |

5. Chemical data: %

C | Mn | S | P | Si |

0.14-0.22 | 0.30-0.65 | ≤0.050 | ≤0.045 | ≤0.30 |

Usage & Applications of Equal Angle

Trusses;

Transmission towers;

Telecommunication towers;

Bracing for general structures;

Stiffeners in structural use.

- Q: How do steel angles compare to other structural materials, such as wood or concrete?

- Steel angles are known for their high strength-to-weight ratio, making them more durable and capable of supporting heavier loads compared to wood or concrete. Additionally, steel angles are resistant to fire, termites, and rot, which are common concerns with wood. While concrete is strong, it is more brittle and can crack under tension, whereas steel angles have better flexibility and can absorb more impact. Overall, steel angles are a preferred choice for structural applications due to their superior strength, durability, and versatility.

- Q: Can steel angles be used in the construction of industrial platforms?

- Yes, steel angles can definitely be used in the construction of industrial platforms. Steel angles are commonly used in construction projects due to their high strength and durability. These angles can be easily welded or bolted together to create a strong and stable platform structure. They are particularly useful in industrial settings where heavy loads and constant foot traffic are expected. Steel angles provide support and stability to the platform, ensuring it can withstand the weight and movement of equipment, machinery, and workers. Additionally, steel angles are resistant to corrosion, making them suitable for use in various environments, including industrial settings where exposure to chemicals, moisture, and extreme temperatures is common. Overall, steel angles are a reliable and cost-effective choice for constructing industrial platforms.

- Q: How do steel angles compare to aluminum angles in terms of strength and durability?

- Compared to aluminum angles, steel angles exhibit superior strength and durability. This is attributed to steel's higher tensile strength and yield strength, enabling it to endure higher levels of force and pressure without warping or fracturing. Moreover, steel boasts better resistance against corrosion, ensuring its structural integrity remains intact for extended durations. In contrast, aluminum is prone to oxidation and may gradually weaken over time. Consequently, when seeking high strength and long-lasting robustness, steel angles emerge as the more favorable option over aluminum angles.

- Q: What are the common sizes and dimensions of steel angles?

- The sizes and dimensions of steel angles differ based on the specific application and industry standards. There exist certain standard sizes commonly employed in construction and structural engineering. An equal angle, which consists of two sides of equal length and a 90-degree angle between them, stands as one of the most frequently used sizes of steel angles. These angles are typically available in sizes ranging from 20x20mm to 200x200mm, with thicknesses varying from 3mm to 20mm. Equal angles may vary in length from 6 meters to 12 meters, although shorter lengths could be accessible. Another type, the unequal angle, comprises two sides of different lengths and a 90-degree angle between them. The sizes and dimensions of unequal angles can significantly vary, depending on project requirements. However, some common sizes for unequal angles range from 40x25mm to 200x150mm, with thicknesses ranging from 3mm to 15mm. Like equal angles, the length of unequal angles can also differ but typically falls between 6 meters and 12 meters. It is important to recognize that these dimensions are not exhaustive, and additional sizes may be obtainable based on the manufacturer and project-specific needs. Moreover, steel angles can be custom fabricated to satisfy unique design requirements. Overall, steel angles serve as versatile structural components applicable in framing, support structures, and bracing, among other uses. The selection of size and dimensions relies on factors such as load capacity, structural requirements, and aesthetic preferences.

- Q: How do you calculate the effective length of a steel angle?

- When calculating the effective length of a steel angle, there are two main factors to consider: the actual length of the angle and the stability of its supported members. To begin, you must determine the actual length of the steel angle. This can be done by physically measuring it or referring to the manufacturer's specifications. It is crucial to have the precise length value for the calculation. Next, evaluate the stability of the angle's supported members. The effective length of the angle is influenced by the specific conditions in which it is being used and supported. There are three primary support conditions to take into account: pinned-pinned, fixed-fixed, and fixed-pinned. In the case of a pinned-pinned support condition, the effective length is equal to the actual length of the angle. This condition assumes that both ends of the angle can freely rotate, allowing the full length to effectively resist applied loads. For a fixed-fixed support condition, the effective length is typically considered as 0.7 times the actual length. This condition assumes that both ends of the angle are rigidly connected, resulting in a reduced effective length due to the increased stiffness of the entire system. In a fixed-pinned support condition, the effective length is usually 0.85 times the actual length. In this scenario, one end of the angle is fixed while the other end can rotate freely, leading to a decreased effective length compared to the actual length. Accurately determining the support conditions of the steel angle is essential for correctly calculating its effective length. In addition, a comprehensive analysis of the angle's behavior should consider other factors such as its material properties, cross-section, and loading conditions.

- Q: What are the load-bearing capacities of different steel angle sizes?

- The load-bearing capacities of various steel angle sizes differ based on multiple factors, such as the material grade, angle size, and angle length. Generally, larger steel angle sizes possess higher load-bearing capacities in comparison to smaller sizes. To determine the load-bearing capacity of a particular steel angle size, it is crucial to take into account its moment of inertia, which measures its resistance to bending. The moment of inertia increases as the angle size becomes larger, resulting in higher load-bearing capacities. Furthermore, the yield strength of the steel used in the angle also plays a significant role in determining its load-bearing capacity. Yield strength refers to the maximum stress that a material can endure without undergoing permanent deformation. Steel angles with higher yield strength can support heavier loads. To obtain accurate load-bearing capacity information for different steel angle sizes, it is important to consult engineering resources such as steel design manuals or structural engineers. These resources provide tables and formulas that consider the specific dimensions and properties of the angle, allowing for the calculation of the maximum allowable load it can safely bear. In conclusion, the load-bearing capacities of various steel angle sizes depend on factors including angle size, material grade, and yield strength. It is necessary to consult reliable engineering resources to obtain accurate load-bearing capacity information for specific steel angle sizes.

- Q: What is the maximum span for a steel angle beam?

- The maximum span for a steel angle beam depends on various factors such as the load it is intended to support, the dimensions of the beam, and the type of steel being used. It is best to consult engineering tables, codes, or a structural engineer to determine the maximum span for a specific steel angle beam in a given application.

- Q: What are the limitations of using steel angles in certain applications?

- When considering the utilization of steel angles in specific applications, one must take into account several limitations. To begin with, steel angles may not be suitable for applications that necessitate high strength or load-bearing capacities. While steel angles are generally robust and long-lasting, they may not be capable of withstanding exceedingly heavy loads or forces. In such instances, alternative types of structural steel sections, such as I-beams or hollow sections, may be more appropriate. Additionally, steel angles may not be ideal for applications that require precise dimensions or tight tolerances. Due to the manufacturing process, steel angles can exhibit slight variations in size and shape, which may be unacceptable in certain applications. In these circumstances, it may be necessary to utilize custom-made or precision-machined steel components. Moreover, steel angles may possess limitations in terms of corrosion resistance. If the application involves exposure to harsh environments, such as marine or chemical settings, the steel angles may deteriorate over time. In such situations, materials with superior corrosion resistance, such as stainless steel or aluminum, may be more suitable. Lastly, steel angles may not deliver the desired aesthetic appearance in certain applications. Although steel angles are commonly employed in structural and industrial settings, they may not be visually appealing or compatible with architectural or decorative applications. In these cases, alternative materials or finishes may be preferred to achieve the desired aesthetics. In summary, while steel angles offer numerous advantages in terms of strength, versatility, and cost-effectiveness, they do have limitations in certain applications. It is crucial to thoroughly evaluate the specific requirements of the application and consider these limitations before deciding to utilize steel angles.

- Q: Can steel angles be used in conveyor systems or material handling equipment?

- Yes, steel angles can be used in conveyor systems or material handling equipment. Steel angles, also known as angle iron, are commonly used in these applications due to their structural strength and versatility. They can be easily welded, bolted, or riveted together to create various framework structures for conveyors and material handling equipment. Steel angles provide stability, support heavy loads, and can be used to construct frames, supports, and guards for conveyor belts, rollers, chutes, and other components. Additionally, steel angles are available in various sizes and thicknesses to suit different application requirements, making them a popular choice in the construction of conveyor systems and material handling equipment.

- Q: How do steel angles perform in terms of durability and longevity?

- Steel angles are renowned for their exceptional durability and longevity. Due to their composition, which includes a high percentage of iron and carbon, steel angles possess remarkable strength and resistance to various forms of wear and tear. They can withstand heavy loads, extreme temperatures, and exposure to corrosive elements, making them highly durable in a wide range of applications. In terms of longevity, steel angles have an impressive lifespan. They are designed to withstand the test of time and retain their structural integrity over extended periods. The inherent strength and resilience of steel angles ensure that they do not degrade easily, making them a reliable choice for long-term use. Furthermore, steel angles require minimal maintenance to preserve their durability and longevity. Regular inspections and cleaning can help prevent the buildup of rust and other forms of corrosion, ensuring that the angles remain in optimal condition throughout their lifespan. Moreover, steel angles can be galvanized or coated with protective layers to enhance their durability and resistance to environmental factors. Galvanization involves applying a layer of zinc to the steel surface, providing an additional barrier against rust and corrosion. Coatings such as epoxy or powder coatings can also be applied to further enhance the durability and longevity of steel angles in specific environments. Overall, steel angles are known for their exceptional durability and longevity. They offer a reliable and long-lasting solution for a variety of structural and construction needs, making them a popular choice in many industries.

Send your message to us

Equal Angle steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords