GB Q235 Unequal Steel Angle

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Unequal Angle Steel:

1.Standards: JIS

2.Length: 6m,9m,12m

3.Material: SS400 or Equivalent

4. Size:

Size (mm) | Mass (mm) | Size (mm) | Mass (mm) |

| 100*75*7 | 9.32 | 100*75*10 | 13.0 |

| 100*75*8 | 10.6 | 100*75*12 | 15.4 |

| 100*75*9 | 11.8 |

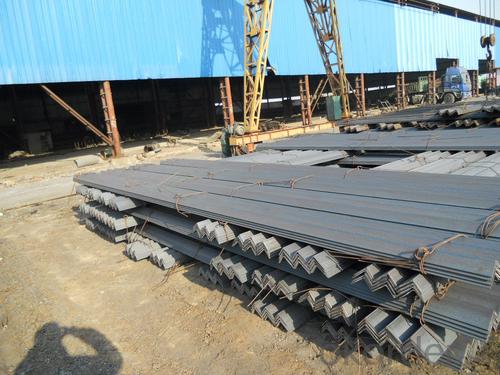

Packaging & Delivery of Unequal Angle Steel

1. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

2. With bundles and load in 20 feet/40 feet container, or by bulk cargo, also we could do as customer's request.

3. Marks:

Color mark: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: There will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

*If you would like to get our price, please inform us the size, standard/material and quantity. Thank you very much for your attention.

- Q: What are the welding techniques used for steel angles?

- Different welding techniques can be used for steel angles, depending on the specific application and desired result. Some commonly used techniques include: 1. Stick welding, also known as Shielded Metal Arc Welding (SMAW), involves using a consumable electrode coated in flux. It is versatile, cost-effective, and suitable for various thicknesses of steel angles. 2. Gas Metal Arc Welding (GMAW), also known as MIG (Metal Inert Gas) welding, utilizes a welding gun to feed a wire electrode. The wire melts and joins with the base metal, while an inert gas shield protects the weld from contamination. GMAW is commonly used for thin to medium thickness steel angles. 3. Flux-Cored Arc Welding (FCAW) is similar to GMAW, but the wire electrode is filled with flux, eliminating the need for external shielding gas. FCAW is suitable for both indoor and outdoor applications and is known for its high deposition rates. 4. Tungsten Inert Gas Welding (GTAW), also known as Gas Tungsten Arc Welding (GTAW), involves using a non-consumable tungsten electrode and a separate filler metal if necessary. This technique produces precise, high-quality welds and is commonly used for thinner steel angles or when precise control is required. 5. Submerged Arc Welding (SAW) uses a continuously fed wire electrode submerged in a granular flux. The flux acts as a protective layer, preventing contamination and enhancing weld quality. SAW is commonly used for thicker steel angles or when high deposition rates are needed. When selecting the appropriate welding technique, it is important to consider factors such as the thickness of the steel angles, the welding environment, and the desired quality and strength of the weld. Consulting with a professional welder or engineer can help determine the best technique for a specific application.

- Q: What are the different uses for stainless steel angles?

- Stainless steel angles have various uses in different industries. They are commonly used as structural components in construction, providing stability and support to buildings and infrastructure. Stainless steel angles are also utilized in manufacturing processes, such as fabrication of machinery, equipment, and vehicles. Additionally, they find application in architectural designs, for creating decorative elements, handrails, and furniture. Overall, stainless steel angles are versatile and durable, making them suitable for a wide range of applications.

- Q: What are the common methods of surface finishing for steel angles?

- There are several common methods of surface finishing for steel angles, depending on the desired aesthetic and functional properties. These methods include: 1. Painting: Painting is one of the most common methods of surface finishing for steel angles. It involves applying a protective coating of paint to the surface to prevent corrosion and enhance its appearance. Different types of paint, such as epoxy, acrylic, or powder coatings, can be used based on specific requirements. 2. Galvanizing: Galvanizing is a popular method for protecting steel angles from rust and corrosion. It involves immersing the steel angle in a bath of molten zinc, which forms a protective layer on the surface. Galvanizing is particularly effective for steel angles exposed to harsh environments or outdoor applications. 3. Powder coating: Powder coating is a process where a dry powder is electrostatically sprayed onto the steel angle and then cured in an oven. This results in a durable and attractive finish that provides excellent resistance to chipping, fading, and corrosion. Powder coating is commonly used when a thicker, more robust finish is desired. 4. Anodizing: Anodizing is a surface finishing process mainly used for aluminum, but it can also be applied to steel angles. It involves creating an oxide layer on the surface of the metal through an electrochemical process. Anodizing provides increased corrosion resistance and can also be used to add color to the steel angle. 5. Shot blasting: Shot blasting is a method of surface preparation that involves bombarding the steel angle with small steel shots at high velocity. This process helps to remove rust, mill scale, and other impurities from the surface, leaving it clean and ready for further finishing processes such as painting or galvanizing. 6. Polishing: Polishing is a surface finishing technique that involves mechanically smoothing and shining the steel angle's surface. This process is typically used to achieve a reflective, mirror-like finish or to remove surface imperfections. These are some of the common methods of surface finishing for steel angles, each offering different benefits and suitable for various applications. The choice of method depends on factors such as the desired appearance, environmental conditions, and specific performance requirements.

- Q: What are the different types of connections for steel angles?

- There are several different types of connections that can be used for steel angles, depending on the specific application and load requirements. Some of the common types of connections for steel angles include: 1. Welded connections: This is the most common type of connection for steel angles. It involves welding the angle to the supporting structure or to another angle to create a strong and rigid connection. Welded connections are often used in applications where high load capacity and stability are required. 2. Bolted connections: Bolted connections involve using bolts to connect the steel angles to the supporting structure or to other angles. This type of connection allows for easy assembly and disassembly and is often used in applications where flexibility and adjustability are important. 3. Riveted connections: Riveted connections are similar to bolted connections, but instead of using bolts, rivets are used to secure the steel angles. Riveted connections provide a strong and durable connection and are commonly used in structural applications. 4. Clip connections: Clip connections involve using steel clips to connect the angles to the supporting structure. This type of connection is often used in applications where ease of installation and flexibility are important. 5. Moment connections: Moment connections are used to transfer bending moments between steel angles and the supporting structure. These connections are designed to provide rigidity and stability in applications where high load capacity and resistance to lateral forces are required. 6. Gusset plate connections: Gusset plate connections involve using steel plates to connect the steel angles to the supporting structure. These connections provide additional strength and stability and are commonly used in applications where heavy loads and high stresses are anticipated. It is important to note that the choice of connection type depends on several factors, including the specific application, load requirements, and design considerations. Consulting with a structural engineer or a professional in steel construction is recommended to ensure the appropriate connection type is selected for a specific project.

- Q: What are the different types of connections used for steel angles in structural applications?

- There are several types of connections that are commonly used for steel angles in structural applications. These connections are crucial for ensuring the stability and strength of the overall structure. 1. Welded connections: Welding is one of the most common methods used to connect steel angles. It involves melting the edges of the steel angles together to form a strong bond. Welded connections are typically used in applications where high strength and rigidity are required. 2. Bolted connections: Bolted connections involve using bolts and nuts to secure the steel angles together. This type of connection provides flexibility as it allows for disassembly and reassembly if needed. Bolted connections are often used in situations where ease of installation and maintenance is important. 3. Riveted connections: Riveting is a traditional method of joining steel angles. It involves inserting a rivet through holes in the steel angles and then flaring the ends to secure them in place. Riveted connections are known for their durability and resistance to corrosion. However, they are less commonly used today due to the time-consuming installation process. 4. Clip connections: Clip connections involve using metal clips or brackets to attach the steel angles. These clips are typically welded or bolted to the steel angles and provide a quick and efficient method of connection. Clip connections are often used in applications where speed and ease of installation are important factors. 5. Gusset plate connections: Gusset plates are steel plates that are used to connect steel angles at their intersection points. They are typically welded or bolted to the angles and provide additional strength and stability to the connection. Gusset plate connections are commonly used in situations where larger forces and moments need to be transferred. Each type of connection has its own advantages and disadvantages, and the choice of connection method depends on several factors including the structural requirements, loadings, and the specific application. It is important to consider the design and engineering specifications to ensure that the chosen connection method is suitable for the intended use in structural applications.

- Q: How much is the weight of 40 * 3 angle steel theory?

- Angle called angle, the steel strip is perpendicular to each other on both sides into the corner. There are equal angles and unequal angles. The two sides of an equal angle steel are equal in width. The specifications are expressed in millimeters of edge width * edge width * edge thickness. Such as "/ 30 x 30 x 3", that is 30 mm width equal angle, edge thickness of 3 mm.

- Q: Where does channel steel use more? Where does angle iron use more?

- Hot rolled stainless steel light channel steel (YB164-63) hot rolled light channel steel is a kind of steel with wide legs and thin wall, which has better economic effect than ordinary hot rolled channel steel. Its specifications range from 5-40#. In 1966, standard specifications ranged from 10-40#. Main applications: building and steel structure etc..

- Q: What are the maintenance requirements for steel angles?

- The maintenance requirements for steel angles typically involve regular cleaning and inspection for signs of corrosion or damage. It is important to remove any dirt or debris that may accumulate on the surface of the steel angles, as they can potentially lead to corrosion. Additionally, it is advisable to apply a protective coating or paint to prevent rusting. Routine inspections should be conducted to identify any signs of wear or structural issues that may require repairs or replacements.

- Q: How do steel angles perform in chemical industry applications?

- Steel angles are widely used in chemical industry applications due to their excellent performance in corrosive environments. These angles, made of high-strength steel, exhibit exceptional resistance to chemicals, acids, and other corrosive substances commonly found in the chemical industry. The chemical industry often involves the handling and processing of various chemicals, which can lead to corrosion and degradation of structural materials. Steel angles, with their high corrosion resistance, provide a reliable and durable solution in such environments. Moreover, steel angles offer excellent load-bearing capacity and structural stability, making them ideal for supporting heavy equipment, tanks, and platforms in chemical plants. Their versatility allows for the construction of various structures and equipment, ensuring the safe and efficient operation of chemical processes. Steel angles can be fabricated into different sizes and shapes, allowing for easy customization to meet specific requirements. This versatility makes them suitable for a wide range of applications such as piping systems, storage tanks, chemical reactors, and support structures. In addition to their corrosion resistance and structural strength, steel angles are also cost-effective. They have a long lifespan, require minimal maintenance, and can withstand extreme temperatures, pressures, and chemical exposures. This durability and low maintenance requirement contribute to reducing downtime and overall operating costs in the chemical industry. Overall, steel angles perform exceptionally well in chemical industry applications by providing a combination of corrosion resistance, structural strength, versatility, and cost-effectiveness. Their ability to withstand harsh chemical environments makes them an essential component in the safe and efficient operation of chemical processes.

- Q: Can steel angles be used in railway infrastructure?

- Yes, steel angles can be used in railway infrastructure. They are commonly used in the construction of railway tracks, bridges, and other structures due to their high strength, durability, and ability to withstand heavy loads. Steel angles provide structural support and stability, making them an essential component in railway infrastructure projects.

Send your message to us

GB Q235 Unequal Steel Angle

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords