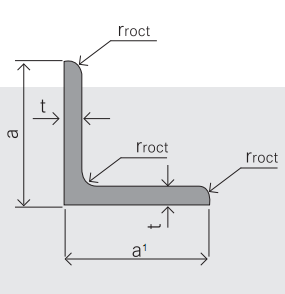

Structure Angle Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25m.t. m.t.

- Supply Capability:

- 80000-100000MTS/YEAR m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Structure Angle Steel

1.Standards:GB,ASTM,BS,AISI,DIN,JIS

2.Length:6m,9m,12m

3.Material:GBQ235B,Q345BorEquivalent;ASTMA36;EN10025,S235JR,S355JR;JISG3192,SS400;SS540.

4. Payment terms:

1).100% irrevocable L/C at sight.

2).30% T/T prepaid and the balance against the copy of B/L.

3).30% T/T prepaid and the balance against L/C

5.Sizes:

|

Sizes: 25mm-250mm | ||

|

a*t | ||

|

25*2.5-4.0 |

70*6.0-9.0 |

130*9.0-15 |

|

30*2.5-6.6 |

75*6.0-9.0 |

140*10-14 |

|

36*3.0-5.0 |

80*5.0-10 |

150*10-20 |

|

38*2.3-6.0 |

90*7.0-10 |

160*10-16 |

|

40*3.0-5.0 |

100*6.0-12 |

175*12-15 |

|

45*4.0-6.0 |

110*8.0-10 |

180*12-18 |

|

50*4.0-6.0 |

120*6.0-15 |

200*14-25 |

|

60*4.0-8.0 |

125*8.0-14 |

250*25 |

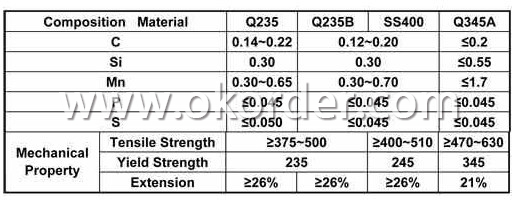

6. Material details:

Usage & Applications of Structure Angle Steel

Trusses;

Transmission towers;

Telecommunication towers;

Bracing for general structures;

Stiffeners in structural use.

Packaging & Delivery of Structure Angle Steel

1. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

2. With bundles and load in 20 feet/40 feet container, or by bulk cargo, also we could do as customer's request.

3. Marks:

Color mark: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: There will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

- Q: Can steel angles be used in residential construction?

- Indeed, residential construction can make use of steel angles. These versatile structural elements find widespread application in various construction projects, including residential buildings. They are commonly employed for framing, reinforcing, and providing structural support in walls, roofs, and floors. In residential construction, steel angles are favored due to their notable strength, durability, and capacity to withstand heavy loads. Their ease of installation, whether by welding, bolting, or screwing, renders them suitable for a wide array of construction endeavors. Furthermore, the corrosion resistance of steel angles can be enhanced through galvanization or coating, assuring their longevity. In essence, steel angles present a dependable and cost-effective option for residential construction.

- Q: Can steel angles be used for soundproofing applications?

- No, steel angles cannot be used for soundproofing applications.

- Q: What is the meaning of the number of angle steel

- The two sides of an equal angle steel are equal in width. The specifications are expressed in millimeters of edge width * edge width * edge thickness. Such as "/ 30 x 30 x 3", that is 30 mm width equal angle, edge thickness of 3 mm. The model can also be used, also the title number, number is the number of centimeters wide, such as the No. 3 angle angle 3#.

- Q: How do steel angles behave under seismic forces?

- The behavior of steel angles under seismic forces varies depending on their design, size, and connection details. Generally, steel angles are commonly utilized in seismic-resistant structures because they can dissipate energy and withstand lateral forces. Here are several important characteristics regarding the behavior of steel angles under seismic forces: 1. Ductility: Steel angles possess a high level of ductility, allowing them to undergo significant deformations without failure. This characteristic is crucial in seismic design as it enables the structure to absorb and dissipate energy during an earthquake, thereby preventing sudden collapse. 2. Flexibility: Steel angles have the ability to flex and bend when subjected to seismic forces, which enables them to absorb energy and minimize the impact on the overall structure. This flexibility aids in distributing the seismic forces evenly throughout the structure, reducing localized damage. 3. Connection behavior: Proper connection design is vital to ensure the performance of steel angles under seismic forces. The connections must be designed to allow for rotation and accommodate the anticipated displacements during an earthquake. Adequate connections prevent the angles from becoming brittle or failing prematurely. 4. Buckling resistance: Steel angles are prone to buckling under compression forces. To enhance their resistance to buckling, lateral bracing or stiffeners are often utilized. These components offer additional support to the angles and help prevent buckling during seismic events. 5. Strength and stiffness: Steel angles possess high strength and stiffness, enabling them to withstand the lateral forces induced by an earthquake. The strength of steel angles can be enhanced by selecting appropriate materials, such as using higher-grade steel with greater yield strength. In conclusion, steel angles are well-suited for seismic-resistant structures due to their ductility, flexibility, and strength. However, their behavior under seismic forces is heavily dependent on proper design, connection details, and adherence to seismic codes and standards. It is crucial to consult with structural engineers and follow best practices to ensure the optimal performance of steel angles in seismic design.

- Q: Can steel angles be welded together?

- Yes, steel angles can be welded together.

- Q: What are the different types of connections used for steel angles in architectural applications?

- There are several types of connections used for steel angles in architectural applications. Some common types include bolted connections, welded connections, and riveted connections. Bolted connections involve using bolts to secure the steel angles together, while welded connections involve fusing the steel angles using heat. Riveted connections, on the other hand, involve using rivets to connect the steel angles together. Each type of connection has its own advantages and disadvantages, and the choice depends on factors such as the load requirements, aesthetics, and ease of construction.

- Q: Can steel angles be drilled or punched for fastening?

- Yes, steel angles can be drilled or punched for fastening.

- Q: Can steel angles be used in fencing?

- Yes, steel angles can be used in fencing. Steel angles are commonly used in fencing applications to provide structural support and stability. They can be used as posts or crossbars, depending on the specific fencing design. Steel angles are strong and durable, making them suitable for withstanding the elements and providing security. They can be easily welded or bolted together to create a sturdy fencing structure. Additionally, steel angles can be galvanized or coated to enhance their resistance to rust and corrosion, ensuring a long-lasting and low-maintenance fencing solution.

- Q: Can steel angles be used in industrial or heavy-duty applications?

- Absolutely, steel angles are a perfect fit for industrial or heavy-duty uses. Renowned for their robustness, endurance, and flexibility, steel angles are highly versatile and find application across a wide range of industries. They play a vital role in providing structural reinforcement, support, and stability to heavy-duty machinery, equipment, and infrastructure projects. Construction, manufacturing, engineering, transportation, and various other industries commonly employ steel angles. Their usage spans frames, supports, bracings, platforms, beams, and trusses, where strength and load-bearing capacity are paramount. Moreover, steel angles can withstand extreme temperatures, harsh weather conditions, and heavy loads, making them ideal for demanding industrial environments. In summary, steel angles are a dependable and efficient choice for industrial or heavy-duty applications, thanks to their strength, durability, and adaptability.

- Q: What are the different methods of surface preparation for steel angles before painting?

- There are various techniques available for preparing steel angles before painting, and the method chosen depends on the condition of the steel surface and the desired level of paint adhesion and durability. One widely used technique is abrasive blasting, also known as sandblasting. This entails directing abrasive particles towards the steel surface to eliminate rust, mill scale, and other contaminants. Abrasive blasting not only cleans the surface but also creates a rough texture, enhancing paint adhesion. Chemical cleaning is another method employed to prepare steel angles for painting. It involves utilizing chemical solutions or solvents to eliminate grease, oil, and other organic contaminants. This technique is particularly effective for stubborn contaminants that cannot be removed by abrasive blasting alone. Mechanical cleaning techniques, such as wire brushing or grinding, can be utilized to eliminate loose rust, scale, and old paint. These methods are suitable for smaller areas or localized rust spots. In certain instances, power tool cleaning may suffice. This involves using power tools like grinders, sanders, or wire brushes to clean the steel surface. However, it is important to ensure that these tools do not create a polished or smooth surface, as this can hinder paint adhesion. After the surface has been cleaned, it is crucial to remove any remaining contaminants by wiping the surface with a solvent or a clean cloth soaked in a suitable solvent. This step guarantees that the surface is free from any residual contaminants that could affect paint adhesion. Lastly, before painting, it is essential to prime the steel angles. Primers provide additional corrosion protection and enhance the adhesion of the topcoat. The choice of primer depends on the specific project requirements, such as exposure to harsh weather conditions or chemical exposure. In conclusion, the various methods of surface preparation for steel angles before painting include abrasive blasting, chemical cleaning, mechanical cleaning, power tool cleaning, solvent wiping, and priming. By selecting the appropriate method, one can ensure that the paint adheres well to the steel surface and provides long-lasting protection against corrosion.

1. Manufacturer Overview

| Location | Hebei, China |

| Year Established | 2003 |

| Annual Output Value | Above US$ 500 Million |

| Main Markets | Southeast Asia; middle east; South Korea; Africa |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 30%-45% |

| No.of Employees in Trade Department | 11-20 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 10,000 square meters |

| No. of Production Lines | 2 |

| Contract Manufacturing | OEM service offered |

| Product Price Range | high; average |

Send your message to us

Structure Angle Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25m.t. m.t.

- Supply Capability:

- 80000-100000MTS/YEAR m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords