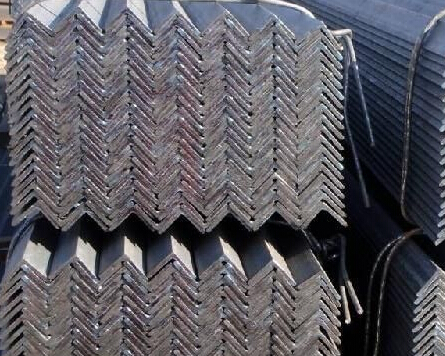

Hot Rolled Equal Angle Steel with Standards:GB,ASTM,BS,AISI,DIN,JIS

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering high quality Hot Rolled Equal Angle Steel with Standards:GB,ASTM,BS,AISI,DIN,JIS at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Hot Rolled Equal Angle Steel with Standards:GB,ASTM,BS,AISI,DIN,JIS are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Steel I-Beams are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Specifications of Equal Angle Steel

1.Standards:GB,ASTM,BS,AISI,DIN,JIS

2.Length:6m,9m,12m

3.Material:GBQ235B,Q345BorEquivalent;ASTMA36;EN10025,S235JR,S355JR;JISG3192,SS400;SS540.

4.Sizes:

EQUAL ANGLES SIZES |

| ||

a(mm) | a1(mm) | thickness(mm) | length |

25 | 25 | 2.5---3.0 | 6M/12M |

30 | 30 | 2.5---4.0 | 6M/12M |

38 | 38 | 2.5 | 6M/12M |

38 | 38 | 3.0---5.0 | 6M/12M |

40 | 40 | 3.0---6.0 | 6M/12M |

50 | 50 | 3 | 6M/12M |

50 | 50 | 3.7---6.0 | 6M/9M/12M |

60 | 60 | 5.0---6.0 | 6M/9M/12M |

63 | 63 | 6.0---8.0 | 6M/9M/12M |

65 | 65 | 5.0---8.0 | 6M/9M/12M |

70 | 70 | 6.0---7.0 | 6M/9M/12M |

75 | 75 | 5.0---10.0 | 6M/9M/12M |

80 | 80 | 6.0---10.0 | 6M/9M/12M |

90 | 90 | 6.0---10.0 | 6M/9M/12M |

100 | 100 | 6.0---12.0 | 6M/9M/12M |

120 | 120 | 8.0-12.0 | 6M/9M/12M |

125 | 125 | 8.0---12.0 | 6M/9M/12M |

130 | 130 | 9.0-12.0 | 6M/9M/12M |

140 | 140 | 10.0-16.0 | 6M/9M/12M |

150 | 150 | 10---15 | 6M/9M/12M |

160 | 160 | 10---16 | 6M/9M/12M |

180 | 180 | 12---18 | 6M/9M/12M |

200 | 200 | 14---20 | 6M/9M/12M |

5. Material details:

Alloy No | Grade | Element (%) | |||||

C | Mn | S | P | Si | |||

|

|

|

|

|

|

| |

Q235 | B | 0.12—0.20 | 0.3—0.7 | ≤0.045 | ≤0.045 | ≤0.3 | |

|

|

|

|

|

|

| |

Alloy No | Grade | Yielding strength point( Mpa) | |||||

Thickness (mm) | |||||||

≤16 | >16--40 | >40--60 | >60--100 | ||||

≥ | |||||||

|

|

|

|

|

| ||

Q235 | B | 235 | 225 | 215 | 205 | ||

Alloy No | Grade | Tensile strength (Mpa) | Elongation after fracture (%) | ||||

Thickness (mm) | |||||||

| ≤16 | >16--40 | >40--60 | >60--100 | |||

≥ | |||||||

|

|

|

|

|

|

| |

Q235 | B | 375--500 | 26 | 25 | 24 | 23 | |

Usage & Applications of Hot Rolled Equal Angle Steel with Standards:GB,ASTM,BS,AISI,DIN,JIS

Trusses;

Transmission towers;

Telecommunication towers;

Bracing for general structures;

Stiffeners in structural use.

Packaging & Delivery of Hot Rolled Equal Angle Steel with Standards:GB,ASTM,BS,AISI,DIN,JIS

1. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

2. With bundles and load in 20 feet/40 feet container, or by bulk cargo, also we could do as customer's request.

3. Marks:

Color mark: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: There will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

- Q: Unequal angle steel

- Unequal angle steel is a cross section, such as the letter "L", with each side of each other vertically angled and of unequal width. Its specifications are expressed in long, wide, short, wide and * thick edges, such as "L30*20*3", i.e., unequal angles with long sides, wide 30mm, short width, 20mm, and 3mm of edge thickness. Can also use the model (number) said that the model represented by a fraction, molecular side length cm wide, the denominator for the short side number of centimeters wide, such as "L3/2#", said the 3 cm long side, short side said 2 centimeters. The specifications for unequal angles are 2.5/1.6#-20/12.5#.

- Q: Are steel angles suitable for supporting rooftop equipment?

- Indeed, rooftop equipment can be supported by steel angles. In the realm of construction and engineering projects, steel angles are widely employed due to their robustness and endurance. They furnish a dependable and firm framework for various rooftop equipment, encompassing HVAC units, solar panels, and communication antennas. Facilitating effortless fabrication and installation, steel angles can be tailored to meet precise load prerequisites, thereby presenting an optimal option for sustaining weighty machinery atop roofs. Furthermore, their resistance to corrosion guarantees prolonged efficacy and minimal upkeep requirements.

- Q: Do steel angles require maintenance?

- Yes, steel angles do require maintenance. While steel is a durable material, it is still susceptible to rust and corrosion, especially when exposed to moisture or harsh environmental conditions. Regular maintenance is necessary to prevent these issues and ensure the longevity of steel angles. Some common maintenance practices include inspecting for any signs of rust or damage, cleaning the surface to remove dirt and debris, and applying protective coatings or paints to prevent corrosion. Additionally, proper storage and handling of steel angles can also contribute to their maintenance. It is important to follow manufacturer guidelines and consult with professionals to determine the specific maintenance requirements for steel angles in different applications.

- Q: How do steel angles contribute to the overall stability of a building?

- The inclusion of steel angles is vital for maintaining the stability of a building. They serve as a support system, reinforcing the structure and increasing its capacity to bear heavy loads. The angular shape of steel angles allows for efficient distribution and transfer of the imposed loads, such as the weight of the floors, walls, and roof, to the foundation. One of the main advantages of steel angles in terms of building stability is their ability to withstand bending and buckling forces. This is due to their L-shaped design, which prevents the structural elements from collapsing or deforming when subjected to substantial loads or external pressures. By resisting bending and buckling, steel angles ensure that the building remains structurally sound and stable, even in adverse conditions like earthquakes or strong winds. Additionally, steel angles are frequently utilized as bracing elements to enhance lateral stability. They are strategically positioned in areas that require reinforcement against horizontal forces, such as wind or seismic activity. By connecting various structural components, steel angles effectively distribute these lateral forces throughout the building, preventing excessive movement or deformation and maintaining overall stability. Apart from their role in load-bearing and bracing, steel angles contribute to the overall stability of a building through their durability and resistance to corrosion. Typically made from high-strength steel, they offer exceptional structural integrity and long-term reliability. This durability ensures that the building can withstand the test of time, remaining stable throughout its lifespan. In conclusion, steel angles play a crucial role in enhancing the overall stability of a building. Their capacity to resist bending and buckling forces, provide lateral stability, and their durability make them an integral component of the building's structural system. By effectively distributing and transferring loads, steel angles guarantee the safety, security, and stability of the building, ensuring the well-being of its occupants and the longevity of the structure.

- Q: How do steel angles contribute to the overall safety of a building?

- Angle irons, also known as steel angles, play a vital role in improving the overall safety of a building. These structural elements have unique properties and advantages that make them widely used in construction. To begin with, steel angles contribute to the structural support and stability of a building. They are commonly utilized to reinforce and strengthen the framework, particularly at critical load-bearing points. By distributing and transferring weight and forces, steel angles prevent excessive deflection or deformation of the building, ensuring its integrity and stability, even under heavy loads or adverse conditions. This reinforcement is particularly crucial in tall buildings or structures located in earthquake-prone or high-wind regions. Moreover, steel angles enhance the safety of a building by acting as protective barriers or shields against potential hazards. For instance, they can be installed as guards or handrails on staircases, balconies, or elevated platforms. These barriers play a vital role in preventing accidental falls or injuries, creating a secure environment for occupants. Steel angles can also be utilized to create safety barriers around machinery or equipment, preventing unauthorized access or accidental contact. Additionally, steel angles contribute to enhancing fire resistance in buildings. Steel is inherently fire-resistant and does not contribute to the spread of flames. By incorporating steel angles into the structural design of a building, it becomes possible to effectively support fire-rated walls, partitions, or fireproof doors. This facilitates the compartmentalization of the building, slowing down the spread of fire and allowing occupants more time to evacuate safely. Furthermore, steel angles offer longevity and durability, making them an ideal choice for long-term safety. Steel is highly resistant to corrosion, weathering, and other environmental factors, ensuring the structural integrity of the building over time. This durability reduces the risk of sudden structural failures or collapses, thereby enhancing overall safety for occupants and nearby structures. In conclusion, steel angles play a significant role in improving the overall safety of a building. Their ability to provide structural support, act as barriers, enhance fire resistance, and offer durability make them crucial components for ensuring the stability and protection of a structure and its occupants.

- Q: How do steel angles contribute to the overall load distribution in a structure?

- Steel angles play a crucial role in contributing to the overall load distribution in a structure. These angled steel pieces, commonly referred to as angle irons or L-shaped beams, are commonly used as structural elements in construction projects. One of the significant contributions of steel angles is their ability to provide stability and support to various components of a structure. These angles are often used as braces, reinforcing the framework and preventing excessive movement or deformation. By distributing the load across different sections of the structure, steel angles help to evenly distribute the weight and stress, ensuring the overall stability and integrity of the building. Moreover, steel angles are frequently used as connections between different structural members. They can be bolted or welded to other beams, columns, or plates, acting as connectors that transfer loads from one component to another. This transfer of loads helps in redistributing the forces and minimizing concentrated stress, thereby enhancing the load-bearing capacity and overall performance of the structure. In addition, steel angles are also utilized in the construction of platforms, stairs, and other support structures. By providing a secure and stable platform for people or equipment, they contribute to the overall load distribution by safely distributing the weight and forces applied to these structures. Overall, steel angles are crucial in ensuring the overall load distribution in a structure by providing stability, support, and connections between various structural components. Their ability to evenly distribute the weight and stress helps in preventing structural failures, ensuring the longevity and safety of the building.

- Q: What are the different types of steel angle connections?

- There are several different types of steel angle connections, including bolted connections, welded connections, and hybrid connections. Bolted connections involve using bolts and nuts to connect steel angles together. Welded connections involve melting the steel angles together using heat and a welding process. Hybrid connections combine elements of both bolted and welded connections, using a combination of bolts and welding to secure the steel angles together.

- Q: What is the minimum radius for a curved steel angle beam?

- The minimum radius for a curved steel angle beam depends on various factors such as the size and thickness of the angle beam, the type of steel used, and the specific application requirements. It is recommended to consult structural engineers or refer to relevant design codes and standards for the specific project to determine the appropriate minimum radius for a curved steel angle beam.

- Q: What is the typical thickness tolerance for steel angles?

- The typical thickness tolerance for steel angles can vary depending on the specific manufacturing standards and requirements. In general, the thickness tolerance for steel angles is typically within a range of +/- 0.005 to 0.010 inches (0.13 to 0.25 mm). However, it is important to note that this tolerance can also be influenced by the size and dimensions of the angle. Larger and thicker steel angles may have slightly looser tolerances compared to smaller and thinner angles. It is always recommended to consult the relevant industry standards or specifications to determine the specific thickness tolerance for a particular steel angle.

- Q: What is the maximum length for a steel angle bracket?

- The length of a steel angle bracket can differ based on the manufacturer and design. Typically, these brackets come in lengths ranging from 1 inch to 8 feet or greater. It should be noted that longer brackets may be susceptible to bending or flexing when subjected to heavy loads. Therefore, it is crucial to consider the intended use and weight-bearing specifications when choosing the suitable length for a steel angle bracket. Moreover, it is advisable to consult the manufacturer's guidelines and specifications to guarantee that the maximum length of the bracket is not surpassed, as this could jeopardize its structural integrity.

Send your message to us

Hot Rolled Equal Angle Steel with Standards:GB,ASTM,BS,AISI,DIN,JIS

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords