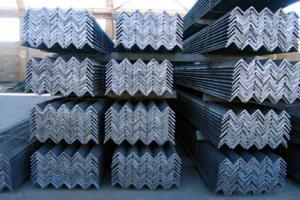

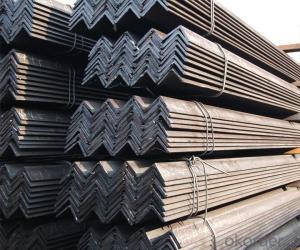

Galvanized Steel Angle

Galvanized Steel Angle Related Searches

Galvanized Steel Angle Stainless Steel Small Trash Can Aluminum Angle Iron Bending Aluminum Angle Stock Right Angle Aluminum Stock Angle Stock Aluminum Aluminum Angle Adjustable Angle TableHot Searches

Steel Mesh Panels For Sale Price For Stainless Steel Scrap Scrap Price For Stainless Steel Price For Stainless Steel Stainless Steel Tank For Sale Stainless Steel Sheets For Sale Cheap High Tea Sets For Sale Stainless Steel Tanks For Sale Stainless Steel For Sale High Density Fiberboard For Sale Solar Hot Water Collectors For Sale Scaffolding For Sale In Uae Scaffolding For Sale In Ireland Scaffolding For Sale In Houston Type Of Inverter For Solar Price Of Shipping Containers For Sale Types Of Inverter For Solar Stock Price For Aluminum Used Solar Inverter For Sale Steel Mesh Panels For SaleGalvanized Steel Angle Supplier & Manufacturer from China

Okorder.com is a professional Galvanized Steel Angle supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Galvanized Steel Angle firm in China.Hot Products

FAQ

- Yes, steel angles are vulnerable to rusting as they are made of steel, which is prone to corrosion when exposed to moisture and oxygen.

- There are several alternatives to steel angles in construction that offer different advantages and disadvantages depending on the specific application. 1. Aluminum angles: Aluminum angles are lightweight and corrosion-resistant, making them a popular choice for outdoor construction projects. They are also easily machinable and have good electrical conductivity. However, aluminum angles may not have the same strength and load-bearing capacity as steel angles, making them less suitable for heavy-duty structural applications. 2. Fiberglass angles: Fiberglass angles are lightweight, non-conductive, and highly resistant to corrosion and chemical damage. They are commonly used in industries where exposure to harsh environments, such as water or chemicals, is a concern. However, fiberglass angles may not have the same strength as steel angles and may require additional reinforcement for heavy loads. 3. Carbon fiber angles: Carbon fiber angles are lightweight, high-strength, and have excellent resistance to corrosion. They are commonly used in applications where weight reduction is critical, such as aerospace and automotive industries. However, carbon fiber angles tend to be more expensive than steel angles and may require specialized manufacturing techniques. 4. Wood angles: Wood angles, typically made from hardwood or engineered wood products, are a traditional alternative to steel angles in construction. They are readily available, cost-effective, and easy to work with. Wood angles are often used in residential and light commercial construction projects. However, wood angles may not have the same strength and durability as steel angles and may be more prone to warping, cracking, or rotting over time. It's important to consider the specific requirements of the construction project, including the load-bearing capacity, environmental conditions, and budget, when choosing an alternative to steel angles. Consulting with a structural engineer or construction professional can help determine the most suitable option for each specific scenario.

- The minimum thickness for a steel angle typically depends on the specific application and the load it needs to bear. However, in general, steel angles are available in various thicknesses ranging from 1/8 inch to 1 inch or more.

- Indeed, it is possible to drill or cut steel angles. Steel angles, being a flexible structural material, find extensive use in diverse construction and manufacturing endeavors. It is effortless to drill them for the purpose of creating holes for bolts, screws, or other fastening elements. Moreover, steel angles can be fashioned into specific lengths or shapes by employing tools like saws, plasma cutters, or shears. The capacity to drill or cut steel angles renders them exceedingly adaptable and fitting for an extensive array of applications.

- Determining the stability of a steel angle column involves considering several crucial factors. The first step is to calculate the slenderness ratio of the column, which is the ratio between its effective length and its least radius of gyration. This can be done using the following formula: Slenderness ratio = (Effective length of column) / (Least radius of gyration) To find the least radius of gyration, the dimensions of the angle section must be used. For a steel angle, an approximation can be made by taking the average of the two legs of the angle section and dividing it by the square root of 3. Once the slenderness ratio is determined, it is necessary to assess whether the column is classified as long or short. If the slenderness ratio is below the critical value, typically around 50 for an angle column, it is considered short, and its stability primarily depends on its strength. In such cases, the column can be designed based on its ability to resist axial compression and flexural buckling. However, if the slenderness ratio surpasses the critical value, the column is classified as long, and its stability depends on its capacity to resist lateral-torsional buckling. In these instances, additional calculations and considerations are required to ensure the column remains stable. For long angle columns, the critical load at which lateral-torsional buckling may occur can be determined using various formulas and methods, such as the Euler formula, the Perry-Robertson formula, or finite element analysis. These calculations take into account various parameters, including the moment of inertia, modulus of elasticity, and length of the column. It is important to acknowledge that stability calculations for steel angle columns can be intricate and necessitate expertise in structural engineering. It is strongly advised to consult with a qualified professional or refer to relevant design codes and standards, such as the American Institute of Steel Construction (AISC) Manual, for accurate and reliable calculations.

- Steel angles have the capability to be utilized as support structures in sports facilities. Due to their superior strength and durability, steel angles are frequently employed in construction projects. They offer exceptional support and stability, rendering them appropriate for a variety of applications in sports facilities, including supporting beams, columns, and trusses. Steel angles are capable of effectively handling heavy loads and enduring the dynamic forces that arise in sports facilities, thus making them a dependable choice for support structures. Furthermore, steel angles can be easily manufactured, allowing for customization to fulfill specific design requirements. In conclusion, steel angles are a versatile and extensively utilized material for support structures in sports facilities.

- Indeed, playground equipment can be manufactured using steel angles. Steel angles, renowned for their robustness and endurance, are extensively utilized in construction and manufacturing industries. These angles can be employed to construct the framework and support structures of diverse playground equipment, including slides, climbing frames, and swing sets. The adaptability of steel angles enables the production of secure and steadfast playground equipment capable of enduring rigorous utilization and adverse weather conditions. Furthermore, steel angles can be effortlessly welded, cut, and molded to meet precise design specifications, rendering them an ideal preference for playground equipment manufacturers.

- There are several different finishes available for steel angles, depending on the desired look and level of protection required. One common finish is hot-dip galvanizing, which involves immersing the steel angle in a bath of molten zinc to create a corrosion-resistant coating. This finish provides excellent protection against rust and is commonly used in outdoor applications or in environments with high humidity or exposure to chemicals. Another option is powder coating, which involves applying a dry powder to the steel angle and then baking it in an oven to create a hard, durable finish. Powder coatings come in a wide range of colors and textures, allowing for customization to match specific design requirements. Additionally, powder coating provides good corrosion resistance and is commonly used in architectural and decorative applications. For a more natural look, steel angles can be left untreated or given a mill finish. Mill finish refers to the surface finish that is produced during the manufacturing process, which typically has a smooth, slightly reflective appearance. This finish is often used in structural applications where aesthetics are not a primary concern. Lastly, steel angles can also be painted or coated with an enamel finish. This involves applying a liquid paint or enamel coating to the surface, which provides protection against rust and can also enhance the appearance of the steel angle. Painted finishes come in a wide range of colors and can be customized to match specific design requirements. Overall, the choice of finish for steel angles depends on factors such as the desired level of corrosion resistance, aesthetic preferences, and the specific application or environment in which the steel angles will be used.