JIS SS400 Steel angle steel angle for construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering JIS SS400 Steel angle steel angle for construction at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

JIS SS400 Steel angle steel angle for construction are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's JIS SS400 Steel angle steel angle for construction are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: Q195 – 235

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

Chinese Standard (H*W*T) | Weight (Kg/m) | 6m (pcs/ton) | Light I (H*W*T) | Weight (Kg/m) | 6m (pcs/ton) | Light II (H*W*T) | Weight (Kg/m) | 6M |

100*68*4.5 | 11.261 | 14.8 | 100*66*4.3 | 10.13 | 16.4 | 100*64*4 | 8.45 | 19.7 |

120*74*5.0 | 13.987 | 11.9 | 120*72*4.8 | 12.59 | 13.2 | 120*70*4.5 | 10.49 | 15.8 |

140*80*5.5 | 16.89 | 9.8 | 140*78*5.3 | 15.2 | 10.9 | 140*76*5 | 12.67 | 13.1 |

160*88*6 | 20.513 | 8.1 | 160*86*5.8 | 18.46 | 9 | 160*84*5.5 | 15.38 | 10.8 |

180*94*6.5 | 24.143 | 6.9 | 180*92*6.3 | 21.73 | 7.6 | 180*90*6 | 18.11 | 9.2 |

200*100*7 | 27.929 | 5.9 | 200*98*6.8 | 25.14 | 6.6 | 200*96*6.5 | 20.95 | 7.9 |

220*110*7.5 | 33.07 | 5 | 220*108*7.3 | 29.76 | 5.6 | 220*106*7 | 24.8 | 6.7 |

250*116*8 | 38.105 | 4.3 | 250*114*7.8 | 34.29 | 4.8 | 250*112*7.5 | 28.58 | 5.8 |

280*122*8.5 | 43.492 | 3.8 | 280*120*8.2 | 39.14 | 4.2 | 280*120*8 | 36.97 | 4.5 |

300*126*9 | 48.084 | 3.4 | 300*124*9.2 | 43.28 | 3.8 | 300*124*8.5 | 40.87 | 4 |

320*130*9.5 | 52.717 | 3.1 | 320*127*9.2 | 48.5 | 3.4 | |||

360*136*10 | 60.037 | 2.7 | 360*132*9.5 | 55.23 | 3 |

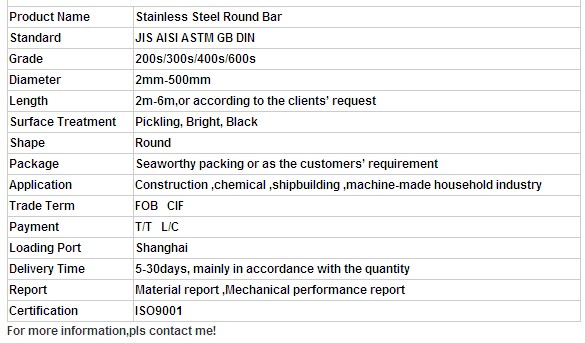

stainless steel round bar

1.Specification:12-300mm

2.Material:304 316

3.Length:standard 6m

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How soon can we receive the product after purchase?

A2: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

- Q:What are the advantages of using silicon-alloy steel round bars?

- There are several advantages to using silicon-alloy steel round bars. Firstly, silicon-alloy steel has excellent strength and durability. It is known for its high tensile strength, which makes it suitable for applications that require heavy-duty performance. This strength also allows it to withstand heavy loads and resist deformation, making it a reliable choice for various mechanical and structural purposes. Secondly, silicon-alloy steel round bars have good heat resistance. The presence of silicon in the alloy improves its ability to handle high temperatures without losing its structural integrity. This makes it ideal for applications that involve exposure to extreme heat, such as in furnace components, exhaust systems, or high-temperature equipment. Additionally, silicon-alloy steel round bars offer excellent corrosion resistance. The alloying elements in silicon-alloy steel, such as chromium and nickel, help create a protective oxide layer on the surface, preventing the metal from corroding and prolonging its lifespan. This makes it suitable for use in marine environments or corrosive atmospheres. Furthermore, silicon-alloy steel round bars have good machinability and weldability. This means that they can be easily formed into various shapes and sizes, making them versatile for different manufacturing processes. The ability to weld silicon-alloy steel allows for easy fabrication and customization, making it a convenient choice for many industries. Lastly, silicon-alloy steel round bars are cost-effective. Compared to other high-performance alloys, silicon-alloy steel is relatively more affordable, making it a cost-effective option for applications that require strength, durability, and resistance to heat and corrosion. In conclusion, the advantages of using silicon-alloy steel round bars include excellent strength and durability, good heat resistance, corrosion resistance, machinability, weldability, and cost-effectiveness. These qualities make silicon-alloy steel a versatile and reliable material for various industrial applications.

- Q:How do you measure the straightness of a steel round bar?

- There exist several methods for measuring the straightness of a steel round bar. One commonly employed approach involves using a straight edge or ruler, which is positioned along the length of the bar to check for any gaps or deviations. If the bar is completely straight, it should make contact with the straight edge throughout its entire length. Any gaps or deviations indicate that the bar is not perfectly straight. Another method involves the utilization of a laser alignment system. This method entails placing the round bar on a flat surface and projecting a line along its length using a laser. The projected line will reveal any deviations or bends in the bar. This method provides a more precise measurement of straightness. Moreover, a dial indicator, a precision measuring instrument, can also be employed. This device includes a small probe that is placed against the surface of the round bar. As the bar is rotated, the dial indicator will measure any variations in the surface, thereby indicating any bends or deviations from straightness. It is worth noting that the required level of straightness will vary depending on the specific application of the steel round bar. In certain cases, a slight deviation may be acceptable, while in others, a high level of straightness may be imperative.

- Q:How do you prevent scaling of steel round bars during heat treatment?

- One way to prevent scaling of steel round bars during heat treatment is by using a protective atmosphere such as nitrogen or hydrogen gas. This atmosphere helps create a barrier between the steel surface and the oxygen in the air, preventing oxidation and scaling. Additionally, applying a coating or using a salt bath can also provide a protective layer on the steel surface, minimizing scaling during the heat treatment process.

- Q:Are steel round bars prone to fatigue failure?

- Fatigue failure is a common occurrence in steel round bars, which can be attributed to repeated cyclic loading or stress. This leads to a gradual weakening of the material, eventually causing it to fail, even if the applied stress is below its ultimate strength. Due to their inherent characteristics, steel round bars, like other structural materials, are susceptible to fatigue failure. Various factors can contribute to fatigue failure in steel round bars, including improper design, inadequate material selection, manufacturing defects, and excessive cyclic loading. Additionally, surface defects, notches, stress concentrations, and corrosive environments can further accelerate the fatigue process. Engineers and designers take several measures to mitigate the risk of fatigue failure. These include implementing appropriate design practices, selecting high-quality materials, conducting thorough inspections, applying stress-relieving treatments, and considering the impact of cyclic loading during the structural design phase. It is important to understand that the susceptibility of steel round bars to fatigue failure depends on multiple factors, such as the specific steel grade, loading conditions, environmental factors, and overall structural design. Therefore, it is crucial to carefully assess these factors and employ appropriate mitigation measures to ensure the safe and reliable performance of steel round bars in various applications.

- Q:How do you measure the surface roughness of a steel round bar?

- One common method to measure the surface roughness of a steel round bar is by using a profilometer. A profilometer is a device that measures the height variations on a surface and provides a numerical value known as the roughness average (Ra). The round bar is placed on a stable surface, and the profilometer's stylus or probe is moved across the surface, recording the vertical movements. The collected data is then used to calculate the Ra value, which indicates the average height of the surface irregularities.

- Q:What are the typical price ranges for steel round bars?

- The price of steel round bars can differ depending on multiple factors, such as the steel type, diameter, length, and quantity purchased. Generally, common carbon steel grades can be priced between $1 and $5 per foot. However, specialty and high-grade steel round bars can have higher prices, ranging from $5 to $20 per foot or more. Moreover, larger diameter or longer length steel round bars may also be more expensive due to increased material and manufacturing costs. It is important to note that these price ranges are approximate and can vary depending on market conditions, supplier pricing, and other factors. To obtain an accurate price range, it is advisable to contact steel suppliers or distributors for specific quotes based on your requirements.

- Q:Can steel round bars be used in marine environments?

- Steel round bars can indeed be utilized in marine settings. Nonetheless, it is crucial to select the appropriate steel variant that is specifically engineered for marine purposes. Among the various options, stainless steel stands out as the most frequently utilized due to its ability to resist corrosion. This is primarily due to its high chromium content, which facilitates the formation of a protective oxide layer on the steel's surface, thereby safeguarding it against corrosion caused by saltwater and other harsh elements. Moreover, stainless steel round bars are renowned for their robustness and durability, making them well-suited for an array of marine applications such as ship construction, offshore structures, and marine equipment. To ensure the enduring performance of steel round bars in marine environments, regular maintenance and proper care are imperative.

- Q:Can steel round bars be bent or formed into shapes?

- Yes, steel round bars can be bent or formed into various shapes through processes such as heating, hammering, or using specialized machinery like bending tools or hydraulic presses.

- Q:What are the advantages of using precipitation-hardening steel round bars?

- There are several advantages of using precipitation-hardening steel round bars. Firstly, these bars offer high strength and toughness, making them suitable for applications that require heavy load-bearing capacity. Secondly, they have excellent corrosion resistance, making them ideal for use in harsh environments or exposed to corrosive elements. Additionally, precipitation-hardening steel round bars can be easily machined and formed into various shapes, providing versatility in design and manufacturing. Lastly, these bars possess good dimensional stability, ensuring consistent performance and reliable results in critical applications.

- Q:What are the different tolerances for steel round bars?

- There are various tolerances for steel round bars, depending on the specific requirements and standards set by different industries and applications. These tolerances ensure that the dimensions and surface conditions of the steel round bars meet the desired specifications. The most common tolerance for steel round bars is the diameter tolerance. This refers to the allowable deviation from the specified diameter. For example, a steel round bar with a diameter tolerance of +/- 0.005 inches means that the actual diameter of the bar can vary within this range. Another important tolerance for steel round bars is the straightness tolerance. This refers to the allowable deviation from a straight line over a specified length of the bar. Straightness tolerances are usually given in terms of the maximum deviation in relation to the length, such as 0.010 inches per foot. Surface finish tolerance is also crucial for steel round bars. It refers to the acceptable variation in the surface texture or roughness of the bar. This tolerance is often specified using parameters such as Ra (average roughness) or Rz (maximum roughness depth). For example, a surface finish tolerance of Ra 0.8 micrometers means that the average roughness of the bar's surface should not exceed this value. In addition to these common tolerances, there may be other specific tolerances based on the intended application of the steel round bars. These can include tolerances for straightness, length, weight, or other dimensional properties. It is important to note that the tolerances for steel round bars can vary depending on the standards followed by different industries and countries. It is always recommended to refer to the relevant standards or specifications to determine the specific tolerances required for a particular application.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

JIS SS400 Steel angle steel angle for construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords