angle steel for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m.t.

- Supply Capability:

- 35000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

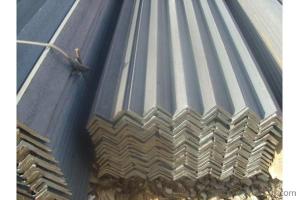

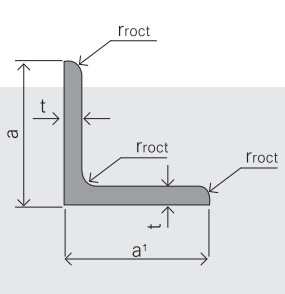

Specifications of Angle Steel

1. Invoicing on theoretical weight or actual weight as customer request

2. Length: 6m, 9m, 12m as following table

3. Sizes

4. Payment terms:

1).100% irrevocable L/C at sight.

2).30% T/T prepaid and the balance against the copy of B/L.

3).30% T/T prepaid and the balance against L/C

5.Material details:

Usage & Applications of Angle Steel

According to the needs of different structures, Angle can compose to different force support component, and also can be the connections between components. It is widely used in various building structures and engineering structures such as roof beams, bridges, transmission towers, hoisting machinery and transport machinery, ships, industrial furnaces, reaction tower, container frame and warehouse etc.

Packaging & Delivery of Angle Steel

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

Production flow of Angle Steel

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

- Q: Can steel angles be cut to size?

- Certainly! Steel angles are capable of being cut to the desired size. These versatile structural materials, commonly referred to as L-shaped angles, find extensive use in the construction and manufacturing sectors. One can effortlessly tailor their length using a variety of cutting tools such as saws, plasma cutters, or angle grinders. This enables customization and guarantees a seamless fit for the steel angles in their intended purpose. It is crucial to adhere to suitable safety precautions and utilize appropriate equipment while cutting these angles, given their formidable strength and durability.

- Q: Can steel angles be used for reinforcing concrete structures?

- Yes, steel angles can be used for reinforcing concrete structures. Steel angles provide additional strength and stability to concrete structures, increasing their load-bearing capacity and resistance to bending and shearing forces. These angles are typically used to reinforce corners, edges, and joints, helping to prevent cracking and enhance the overall durability of the structure.

- Q: What are the typical lengths of steel angles available in the market?

- The market offers a range of steel angle lengths to meet specific project needs and requirements. While there are standard lengths readily available, ranging from 20 to 40 feet, such as 20, 25, 30, 35, and 40 feet, customization is also possible through special orders or fabrication. This flexibility allows for meeting precise project requirements in construction and industrial applications, where steel angles are used for structural support, framing, and bracing.

- Q: Are steel angles suitable for mezzanine floor construction?

- Yes, steel angles are suitable for mezzanine floor construction. Steel angles are commonly used in mezzanine floor construction due to their structural strength and durability. They provide excellent support and stability, making them an ideal choice for supporting the weight of the mezzanine floor and any loads placed on it. Steel angles can be easily bolted or welded together to create a strong framework for the mezzanine floor. Additionally, steel angles can be customized to fit specific design requirements, allowing for flexibility in mezzanine floor construction. Overall, steel angles are a reliable and cost-effective solution for mezzanine floor construction.

- Q: How do steel angles contribute to the overall load distribution in a structure?

- Steel angles play a crucial role in contributing to the overall load distribution in a structure. These angled steel pieces, commonly referred to as angle irons or L-shaped beams, are commonly used as structural elements in construction projects. One of the significant contributions of steel angles is their ability to provide stability and support to various components of a structure. These angles are often used as braces, reinforcing the framework and preventing excessive movement or deformation. By distributing the load across different sections of the structure, steel angles help to evenly distribute the weight and stress, ensuring the overall stability and integrity of the building. Moreover, steel angles are frequently used as connections between different structural members. They can be bolted or welded to other beams, columns, or plates, acting as connectors that transfer loads from one component to another. This transfer of loads helps in redistributing the forces and minimizing concentrated stress, thereby enhancing the load-bearing capacity and overall performance of the structure. In addition, steel angles are also utilized in the construction of platforms, stairs, and other support structures. By providing a secure and stable platform for people or equipment, they contribute to the overall load distribution by safely distributing the weight and forces applied to these structures. Overall, steel angles are crucial in ensuring the overall load distribution in a structure by providing stability, support, and connections between various structural components. Their ability to evenly distribute the weight and stress helps in preventing structural failures, ensuring the longevity and safety of the building.

- Q: Can steel angles be used for stairs?

- Stairs can indeed utilize steel angles. The construction industry frequently employs steel angles for a multitude of purposes, including the creation of staircases. These angles are frequently employed to provide the necessary structural support for stair treads and risers. By incorporating steel angles, stairs gain durability and stability, rendering them a favored option for both residential and commercial structures. Moreover, steel angles boast adaptability for stair construction as they can be effortlessly tailored and fabricated to meet unique design specifications.

- Q: How do you calculate the effective length of a steel angle?

- To calculate the effective length of a steel angle, you need to consider two main factors: the actual length of the angle and the stability of the angle's supported members. Firstly, determine the actual length of the steel angle. This can be measured physically or obtained from the specifications provided by the manufacturer. Ensure that you have the accurate length value for the calculation. Next, assess the stability of the angle's supported members. The effective length of the angle is influenced by the conditions under which it is being used and supported. There are three primary support conditions to consider: pinned-pinned, fixed-fixed, and fixed-pinned. For a pinned-pinned support condition, the effective length is equal to the actual length of the angle. This condition assumes that both ends of the angle can freely rotate, resulting in the full length being effective in resisting the applied loads. In a fixed-fixed support condition, the effective length is typically considered as 0.7 times the actual length. This condition assumes that both ends of the angle are rigidly connected, reducing the effective length due to the increased stiffness of the overall system. For a fixed-pinned support condition, the effective length is usually 0.85 times the actual length. In this case, one end of the angle is fixed while the other end can freely rotate, resulting in a reduced effective length compared to the actual length. It is essential to correctly determine the support conditions of the steel angle to accurately calculate its effective length. Additionally, other factors like the angle's material properties, cross-section, and loading conditions should be considered in a comprehensive analysis of the angle's behavior.

- Q: Can steel angles be used for manufacturing decorative brackets?

- Yes, steel angles can be used for manufacturing decorative brackets. The angles can be cut and shaped to create various designs, making them suitable for decorative purposes while also providing the necessary strength and durability.

- Q: How do you specify steel angles in a construction project?

- In a construction project, steel angles are specified based on their dimensions, grade, and any additional requirements. The dimensions of a steel angle are typically specified as the length of each leg and the thickness of the material. For example, a common specification might be "2-inch by 2-inch by 1/4-inch steel angle". The grade of steel angle is also important to specify as it determines the strength and durability of the material. Common grades for steel angles include A36, A572, and A588. The specific grade chosen will depend on the structural requirements and environmental conditions of the project. In addition to dimensions and grade, any additional requirements such as corrosion resistance, fire resistance, or special finishes should also be specified. For example, if the steel angles will be exposed to outdoor elements, they may need to be hot-dip galvanized or coated with a protective paint. It is important to consult relevant codes and standards, such as the American Institute of Steel Construction (AISC) manual, for guidance on specifying steel angles in a construction project. These codes provide guidelines on allowable stress, design criteria, and other factors to ensure the safe and efficient use of steel angles in structural applications.

- Q: Can steel angles be used in seismic zones?

- Yes, steel angles can be used in seismic zones. Steel angles are commonly used in seismic design and construction as they provide structural support and stability. However, it is important to ensure that the steel angles are designed and installed according to the specific building codes and regulations for seismic zones to ensure their effectiveness and safety.

Send your message to us

angle steel for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m.t.

- Supply Capability:

- 35000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords