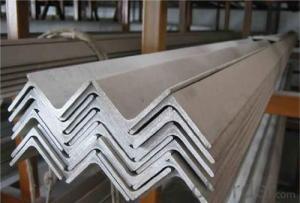

Angel steel for construction high quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

General Informaiton of Stainless Steel Angle Bar

1. Grade: SS200, 300,400 series

2. Size: 25×25×3 mm-100×100×10mm

3. Process: HRAP

4. Length: 2-6m

5. Shape: Equal

6. Delivery: within 20 days

7. MOQ: 1 ton

8. Certificate: ISO 9001:2008, SGS

9. Package: Standard Export Packing, or put into wooden boxes according to your requirement

10. Application: Construction, Marine, Industry etc.

Specification of Stainless Steel Angle Bar

Name | Stainless Steel Angles | |||||

Standard | ASTM A554, A312, A249, A269 and A270 | |||||

Material Grade | 304,316,201,202, 316L,430 | |||||

Length | 6m or as customers' request | |||||

Tolerance | a) Thickness: +/-0. 15mm | |||||

b) Length: +/-4. 5mm - 0mm | ||||||

Surface | 180G, 320G, 400G Satin / Hairline(Matt Finish, Brush, Dull Finish) 400G, 500G, 600G or 800G Mirror finish | |||||

Application | Decoration construction, upholstery, industry instruments | |||||

Test | Squash test, Extended test, Water pressure test, Crystal rot test, Heat treatment, NDT | |||||

Chemical Composition of Material | Composition Material | 201 | 202 | 304 | 316 | 430 |

C | ≤0.15 | ≤0.15 | ≤0.08 | ≤0.08 | ≤0.12 | |

Si | ≤1.00 | ≤1.00 | ≤1.00 | ≤1.00 | ≤1.00 | |

Mn | 5.5-7.5 | 7.5-10 | ≤2.00 | ≤2.00 | ≤1.00 | |

P | ≤0.06 | ≤0.06 | ≤0.045 | ≤0.045 | ≤0.040 | |

S | ≤0.03 | ≤0.03 | ≤0.030 | ≤0.030 | ≤0.030 | |

Cr | 16-18 | 17-19 | 18-20 | 16-18 | 16-18 | |

Ni | 3.5-5.5 | 4-6 | 8-10.5 | 10-14 | ||

Mo | 2.0-3.0 | |||||

Mechanical Property | Material Item | 201 | 202 | 304 | 316 | |

Tensile Strength | ≥535 | ≥520 | ≥520 | ≥520 | ||

Yield Strength | ≥245 | ≥205 | ≥205 | ≥205 | ||

Extension | ≥30% | ≥30% | ≥35% | ≥35% | ||

Hardness (HV) | <253 | <253 | <200 | <200 | ||

- Q: What are the standard dimensions of steel angles?

- The standard dimensions of steel angles vary depending on the specific type of angle, such as equal or unequal angle. In general, the standard dimensions of steel angles are measured by the length of each leg and the thickness of the material. Equal steel angles typically have equal legs, meaning both sides of the angle are of equal length. The standard dimensions for equal steel angles range from 20mm x 20mm x 3mm to 200mm x 200mm x 24mm. These measurements refer to the length of each leg and the thickness of the angle. Unequal steel angles, on the other hand, have legs of different lengths. The standard dimensions for unequal steel angles range from 40mm x 25mm x 4mm to 200mm x 150mm x 12mm. Again, these measurements indicate the length of each leg and the thickness of the angle. It is important to note that these dimensions are just standard measurements, and custom sizes can also be manufactured based on specific requirements. Additionally, these measurements may vary slightly depending on different steel standards and regional practices.

- Q: How do steel angles contribute to the overall lateral stability of a structure?

- The overall lateral stability of a structure is improved by steel angles in various ways. Firstly, they serve as bracing members to counteract lateral forces like wind or seismic loads. By linking the angles to the building's main structural components, they assist in distributing these forces and preventing the structure from collapsing or deforming under the applied load. Additionally, steel angles can be utilized as stiffeners to boost the stiffness and rigidity of crucial structural parts. By incorporating angles into beams, columns, or other elements, their resistance to bending or buckling is heightened, thereby enhancing the overall lateral stability of the structure. Moreover, steel angles can act as shear connectors between different structural elements. For instance, by welding or bolting angles to beams, they establish a connection that facilitates the transfer of shear forces between the components. This is essential for ensuring that the structure remains stable and capable of withstanding lateral loads without significant deformation or failure. Furthermore, steel angles can be employed as diagonal members in truss systems. By forming diagonal bracing, they aid in evenly distributing the applied loads across the structure, preventing excessive lateral displacements and maintaining the overall stability of the building. In conclusion, steel angles play a crucial role in enhancing the lateral stability of a structure. Their application as bracing members, stiffeners, shear connectors, and diagonal members all contribute to distributing and resisting lateral forces, guaranteeing that the structure remains stable and capable of withstanding external loads.

- Q: What is the typical yield strength of steel angles?

- The typical yield strength of steel angles can vary depending on the specific grade of steel used, but it is typically around 36,000 to 50,000 pounds per square inch (psi).

- Q: Can steel angles be easily modified or customized on-site?

- Steel angles have the capability to be effortlessly modified or customized on-site. One can cut, drill, weld, and bend steel angles to meet specific requirements. This adaptability permits convenient customization and adjustment of steel angles to fulfill diverse construction or fabrication needs. Moreover, on-site modifications are frequently essential to guarantee accurate fitting and alignment during installation. By utilizing the appropriate tools and expertise, steel angles can be modified and customized on-site with minimal difficulty.

- Q: How are steel angles protected against corrosion?

- There are various techniques available to protect steel angles from corrosion. One commonly used method entails applying a protective coating. This can be accomplished by either painting the steel angles with a paint that resists corrosion or by employing galvanization, which involves immersing the steel angles in molten zinc to create a protective layer on the surface. Another approach to prevent corrosion in steel angles is the application of a corrosion inhibitor. This involves introducing chemicals or compounds to the steel angles that impede or decelerate the corrosion process. Additionally, conducting regular inspections and performing proper maintenance can aid in detecting and addressing any indications of corrosion before they result in significant damage.

- Q: What are the maintenance requirements for steel angles?

- The maintenance needs of steel angles can differ depending on the environment and conditions they are exposed to. However, there are general guidelines that should be followed to ensure their durability and functionality. Firstly, it is crucial to regularly inspect steel angles for any signs of damage or corrosion. This can be done by visually examining the angles and checking for discoloration, rust, or surface irregularities. If any issues are found, they should be addressed promptly to prevent further deterioration. Regularly cleaning the steel angles is also essential. A mild detergent or soap solution and a soft cloth or sponge can be used for this purpose. It is important to avoid using abrasive cleaners or tools that can scratch the surface of the angles. After cleaning, the angles should be rinsed thoroughly with clean water and dried completely to prevent moisture accumulation. To protect the steel angles from corrosion, it is recommended to apply a protective coating or paint. This can create a barrier against moisture and other corrosive elements. It is important to choose a coating or paint specifically designed for steel and suitable for the environment in which the angles are used. Regular inspection and touch-up of the coating or paint may be necessary to ensure its effectiveness. Additionally, it is crucial to prevent prolonged exposure to harsh chemicals or corrosive substances that can harm the steel angles. If the angles are installed in an environment where contact with such substances is possible, appropriate protective measures, such as chemical-resistant coatings or barriers, should be employed. Finally, it is advisable to follow any specific maintenance recommendations provided by the manufacturer or supplier of the steel angles. They may have additional guidelines or requirements based on the specific type or grade of steel being used. By adhering to these maintenance requirements, steel angles can remain in good condition, maintain their structural integrity, and deliver long-lasting performance.

- Q: How do you calculate the torsional strength of a steel angle?

- The torsional strength of a steel angle can be calculated by determining the moment of inertia of the angle cross-section and then applying the torsion formula, which relates the applied torque to the torsional stress and the polar moment of inertia.

- Q: What is the typical size range for steel angles?

- The typical size range for steel angles can vary depending on the specific application and industry. However, in general, steel angles are available in a range of sizes that typically fall within the dimensions of 20-200 millimeters (mm) in width and 3-20 mm in thickness. The length of steel angles can vary as well, typically ranging from 3 to 12 meters. These dimensions allow for a versatile range of applications, including structural support in construction, manufacturing of machinery and equipment, and various architectural uses. It's important to note that these size ranges are common, but there may be variations and custom sizes available depending on the specific requirements of a project.

- Q: What are the different types of steel angles used in architectural applications?

- There are several different types of steel angles that are commonly used in architectural applications. One type is the equal leg angle, also known as a L-shaped angle or L-bar. This type of angle has equal legs that form a 90-degree angle, making it suitable for various structural applications such as framing, bracing, and support. Another common type is the unequal leg angle, also known as a L-shaped angle or L-bar with unequal legs. This angle has one leg longer than the other, allowing for versatile applications where different lengths are required. It can be used for various architectural purposes such as edging, corner protection, and decorative accents. A third type of steel angle used in architectural applications is the bent angle. This angle is formed by bending a piece of flat steel to the desired angle. Bent angles are often used in architectural designs to create curved or unique-shaped structures, adding visual interest and enhancing aesthetics. Lastly, there is the perforated angle, which is an angle with holes punched along its length. This type of angle is commonly used in architectural applications where ventilation, drainage, or lightweight structural support is required. The perforations allow for airflow, water drainage, or the attachment of additional components. Overall, the different types of steel angles used in architectural applications provide architects and designers with a wide range of options to suit their specific project requirements, whether it be structural stability, aesthetic design, or functional purposes.

- Q: How do steel angles contribute to LEED certification?

- Steel angles can contribute to LEED (Leadership in Energy and Environmental Design) certification in several ways. Firstly, steel angles are often made from recycled steel, which helps reduce the demand for virgin materials and minimizes the environmental impact of steel production. Secondly, steel angles are durable and have a long lifespan, which means they require less maintenance and replacement over time. This reduces the amount of waste generated during the lifecycle of a building and can contribute to LEED's Materials and Resources credit for reducing construction and demolition waste. Moreover, steel angles can be used to create efficient structural systems that allow for open and flexible building designs. This can contribute to LEED's Innovation in Design credit for providing exceptional energy and resource efficiency. Additionally, steel angles can be easily integrated into a building's design to support sustainable features such as solar panels, green roofs, or rainwater harvesting systems. These sustainable features can help a building achieve LEED credits for energy efficiency, renewable energy, and water efficiency. In summary, steel angles contribute to LEED certification by being made from recycled materials, offering durability and longevity, enabling efficient structural systems, and supporting the integration of sustainable features.

Send your message to us

Angel steel for construction high quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches