Steel Structure in Angle Form with All Sizes and All Standards

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Steel Structure in Angle Form Description:

Steel structure in angle form is a main kind of structure steel and the section is like a letter L. We use steel structure in angle form for structure construction. Steel structure in angle form can be erected as soon as the materials are delivered on site. High strength, stiffness, toughness, and ductile properties are advantages of this kind of Steel structure in angle form.

2. Main Features of Steel Structure in Angle Form:

• Strength - Having high strength, stiffness, toughness, and ductile properties, structural steel is one of the most commonly used materials in commercial and industrial building construction.

• Constructability - Steel equal angle Bar can be developed into nearly any shape, which are either bolted or welded together in construction. Structural steel can be erected as soon as the materials are delivered on site, whereas concrete must be cured at least 1–2 weeks after pouring before construction can continue, making steel a schedule-friendly construction material.

• Fire resistance - Steel is inherently a noncombustible material. However, when heated to temperatures seen in a fire scenario, the strength and stiffness of the material is significantly reduced. The steel equal angle bar can be enveloped in sufficient fire-resistant materials, increasing overall cost of steel structure buildings.

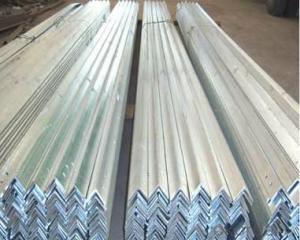

3. Steel Structure in Angle Form Images:

4. Steel Structure in Angle Form Specification:

Angle | KG/M | Angle | KG/M | Angle | KG/M | Angle | KG/M |

20X20X3 | 0.889 | 60X60X5 | 4.570 | 90X90X8 | 10.946 | 130X130X12 | 23.600 |

20X20X4 | 1.145 | 60X60X6 | 5.427 | 90X90X9 | 12.220 | 130X130X13 | 25.400 |

25X25X2 | 0.763 | 63X63X4 | 3.907 | 90X90X10 | 13.476 | 130X130X14 | 27.200 |

25X25X3 | 1.124 | 63X63X5 | 4.822 | 90X90X15 | 15.940 | 130X130X16 | 30.900 |

25X25X4 | 1.459 | 63X63X6 | 5.721 | 100X100X6 | 9.366 | 140X140X10 | 21.488 |

30X30X2 | 0.922 | 63X63X8 | 7.469 | 100X100X7 | 10.830 | 140X140X12 | 25.522 |

30X30X3 | 1.373 | 63X63X10 | 9.151 | 100X100X8 | 12.276 | 140X140X14 | 29.490 |

30X30X4 | 1.786 | 70X70X4 | 4.372 | 100X100X10 | 15.120 | 140X140X15 | 31.451 |

36X36X3 | 1.656 | 70X70X5 | 5.397 | 100X100X12 | 17.898 | 140X140X16 | 33.393 |

5. FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about the corrosion of the products?

When the steel equal angle bar in contact with water, can corrode, creating a potentially dangerous structure. Measures must be taken in structural steel construction to prevent any lifetime corrosion. The steel can be painted, providing water resistance. Also, the fire resistance material used to envelope steel is commonly water resistant.

②How to inspect the quality?

We have a professional inspection group which belongs to our company. We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③What is the difference between steel angle bar and traditional material?

Steel equal angle bar differs from concrete in its attributed compressive strength as well as tensile strength.

- Q: How do you cut steel angles?

- Steel angles can be cut using various methods such as using a metal-cutting saw, an angle grinder with a cutting disc, or a plasma cutter. It is important to ensure proper safety precautions, use appropriate tools, and follow the manufacturer's instructions for the specific cutting method being used.

- Q: Can steel angles be used in automotive applications?

- Yes, steel angles can be used in automotive applications. Steel angles are commonly used in the automotive industry for various applications such as frames, chassis, supports, brackets, and reinforcements. This is because steel angles offer high strength, durability, and resistance to impact and vibrations, making them suitable for withstanding the harsh conditions and demanding loads experienced in automotive applications. Additionally, steel angles can be easily welded or bolted together, providing flexibility in designing and constructing automotive components. Overall, steel angles are a reliable and cost-effective choice for automotive applications due to their strength, versatility, and ability to withstand the rigorous demands of the industry.

- Q: Are steel angles cost-effective?

- Yes, steel angles are cost-effective. Steel angles are widely used in various industries and construction projects due to their versatility and durability. They are highly cost-effective because they are easy to manufacture, readily available, and have excellent strength-to-weight ratios. Steel angles also have a long lifespan, reducing the need for frequent replacements or repairs, which can save on maintenance costs in the long run. Additionally, steel angles are recyclable, making them an environmentally friendly and sustainable choice. Overall, the cost-effectiveness of steel angles makes them a popular choice for structural and architectural applications.

- Q: What does "L125*8" stand for in steel structures?

- Equal angle steel, width 125, wall thickness 8

- Q: Can steel angles be used for framing purposes?

- Yes, steel angles can be used for framing purposes. They are commonly used in construction for providing structural support and stability in framing applications, such as in the construction of buildings, bridges, and other structures. Steel angles offer strength and durability, making them an ideal choice for framing purposes.

- Q: How do you store steel angles to prevent damage?

- To store steel angles and prevent damage, it is important to follow some best practices. Firstly, ensure that the storage area is clean, dry, and free from any sources of moisture or humidity. Moisture can lead to corrosion and rusting of the angles, causing damage over time. It is recommended to store steel angles indoors, in a well-ventilated area, away from direct sunlight or extreme temperature fluctuations. This will help minimize the risk of any potential damage caused by exposure to the elements. When stacking steel angles, it is crucial to use proper supports or racks to prevent them from bending or warping under their own weight. Avoid stacking them too high, as it can cause instability and potential accidents. Using pallets or other suitable storage systems can help maintain the integrity of the angles and reduce the risk of damage. Moreover, it is advisable to separate different sizes and types of steel angles to prevent scratching, chipping, or other physical damage. Placing protective material, such as plastic or rubber mats, between layers or individual angles can offer an additional layer of protection. Regular inspections of the storage area are critical to identify any signs of damage, such as rust spots or deformation, early on. In case of any issues, it is essential to address them promptly to prevent further deterioration and ensure the quality of the steel angles.

- Q: How are steel angles measured?

- Two main dimensions are used to measure steel angles: the length of each leg and the thickness of the material. Each leg's length refers to the distance from the intersection point of the two legs to the end of each leg. This measurement is typically expressed in inches or millimeters. The material's thickness, also known as the gauge, measures the width of the steel angle. It is commonly expressed in fractions of an inch or millimeters. To provide a comprehensive measurement, steel angles are often described by combining these two dimensions. For instance, a typical specification could be "2 x 2 x 1/4," indicating that the steel angle has legs measuring 2 inches in length, a thickness of 1/4 inch, and both legs are of equal length. It's worth noting that steel angles can be measured differently depending on the specific industry or region. Metric measurements may be used in some industries, while others may prefer imperial measurements. Therefore, it's always advisable to verify the measuring standards used in a particular context to ensure accurate understanding and communication.

- Q: Can steel angles be used for overhead cranes?

- Yes, steel angles can be used for overhead cranes. Steel angles provide structural support and stability to the crane, making them a suitable choice for constructing the framework of overhead cranes. They are strong, durable, and capable of withstanding heavy loads, making them an ideal material for such applications.

- Q: What are the different methods for fastening steel angles?

- Some different methods for fastening steel angles include using welding, bolting, riveting, and using adhesive bonding.

- Q: Can steel angles be used in architectural sculptures and installations?

- Yes, steel angles can definitely be used in architectural sculptures and installations. Steel angles provide structural support and stability, making them ideal for creating intricate and visually appealing designs. They can be bent, welded, or cut to fit specific requirements, offering versatility in creating unique architectural forms. Additionally, steel angles are durable and weather-resistant, making them suitable for outdoor installations.

Send your message to us

Steel Structure in Angle Form with All Sizes and All Standards

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords