First-class Steel-work Construction

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Structure

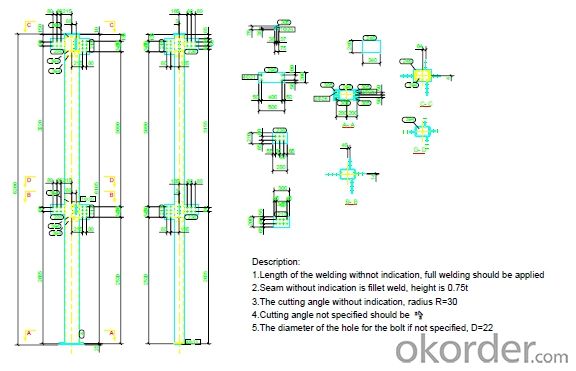

Description:

1.Length of the welding withnot indication,full welding should be applied

2.Seam without indication is fillet weld,height is 0.75t

3.The cutting angle without indication,radius R=30

4.Cutting angle not specified should be 20/20

5.The diameter of the hole for the bolt if not specified, D=22

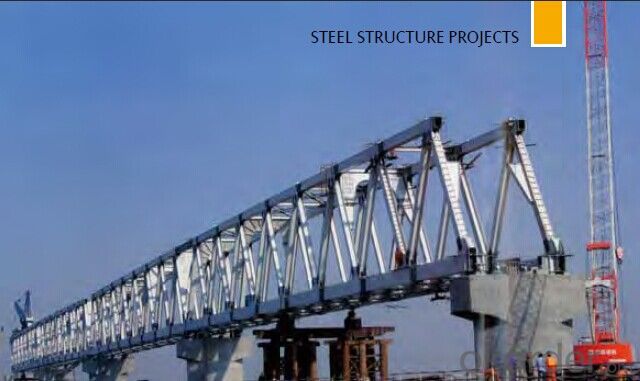

Project Reference:

Inner Mongolia Shangdu Power Plant is the main source

of west-east power transmission project with total

incestment of 5137 million Yuan. 1,900 tons for the steel

structure of the project with maximum thickness 60mm-

75mm.

- Q: What are the key considerations in the design of steel structures for educational campuses?

- The key considerations in the design of steel structures for educational campuses include factors such as safety, flexibility, sustainability, aesthetics, and cost-effectiveness. The structures need to be designed to withstand various loads and forces, ensuring the safety of students, staff, and visitors. Flexibility is important to accommodate future expansions or changes in the layout. Sustainable design principles should be incorporated to minimize environmental impact and promote energy efficiency. Aesthetics play a role in creating a welcoming and inspiring learning environment. Lastly, cost-effectiveness is crucial to optimize the budget and ensure the long-term viability of the structures.

- Q: How do steel structures contribute to the overall energy efficiency of a building?

- Steel structures can contribute significantly to the overall energy efficiency of a building in several ways. Firstly, steel is a highly durable and long-lasting material, which means that steel structures require minimal maintenance and replacement over time. This durability reduces the energy consumption associated with repairs and replacements, ultimately increasing the overall energy efficiency of the building. Additionally, steel is a lightweight material compared to other construction materials like concrete or wood. This lightweight characteristic allows for more efficient transportation and installation, reducing the energy consumption associated with construction processes. The use of steel structures also allows for greater flexibility in design and construction, enabling architects and engineers to optimize energy efficiency by incorporating features such as large windows for natural lighting and ventilation. Furthermore, steel structures have excellent thermal properties. They have a high thermal conductivity, which means they can efficiently transfer heat and cold across the building. This property allows for better temperature regulation and energy management within the building. Steel structures can be designed to incorporate insulation materials effectively, reducing heat loss during winter and heat gain during summer. With proper insulation, the energy required for heating and cooling can be significantly reduced, leading to increased energy efficiency. Moreover, steel is a recyclable material, and its production process has become more environmentally friendly over the years. The recycling of steel reduces the need for raw material extraction and the energy-intensive process of steel production from scratch. This contributes to the overall energy efficiency of a building by reducing the embodied energy and carbon footprint associated with construction. In conclusion, steel structures contribute to the overall energy efficiency of a building through their durability, lightweight nature, thermal properties, and recyclability. By reducing the energy consumption required for maintenance, transportation, heating, and cooling, steel structures can help create more sustainable and energy-efficient buildings.

- Q: How are steel structures designed for wind-induced vibrations?

- Steel structures are designed for wind-induced vibrations by considering various factors such as wind speed, direction, and frequency. Engineers use dynamic analysis and wind tunnel testing to determine the structural response to wind loads. They also incorporate measures like aerodynamic shaping, dampers, bracing, and stiffening elements to minimize vibrations and ensure the safety and stability of the steel structure.

- Q: How are steel structures connected together?

- Steel structures are commonly connected together using various methods, such as bolting, welding, or riveting. These connections ensure the stability and strength of the structure, allowing different steel members to be joined securely and efficiently.

- Q: What are the common design considerations for steel structures in educational institutions?

- Some common design considerations for steel structures in educational institutions include factors such as load-bearing capacity, durability, flexibility for future expansions or modifications, acoustics and soundproofing, fire safety, energy efficiency, and aesthetic appeal. Additionally, considerations must be given to the specific needs and requirements of the educational institution, such as the type of activities and equipment that will be used within the structure, as well as compliance with building codes and regulations.

- Q: What are the design considerations for steel manufacturing plants?

- When designing steel manufacturing plants, there are several important considerations that need to be taken into account. These considerations include: 1. Site Selection: The location of the plant is crucial and should be chosen based on factors such as proximity to raw materials, availability of utilities and transportation infrastructure, and potential environmental impacts. 2. Layout and Flow: The layout of the plant should be carefully planned to ensure efficient material flow and minimize movement of workers and equipment. The arrangement of production lines, storage areas, and support services should be optimized for smooth operations. 3. Equipment Selection: The selection of equipment plays a vital role in steel manufacturing plants. The chosen equipment should be capable of handling the required production capacity, be efficient in terms of energy consumption, and comply with safety and environmental regulations. 4. Safety and Environmental Considerations: Safety is of utmost importance in steel manufacturing plants due to the presence of heavy machinery and high temperatures. Adequate safety measures should be implemented to protect workers from potential hazards. Additionally, environmental considerations, such as air and water pollution control systems, should be incorporated to minimize the impact on the surrounding environment. 5. Energy Efficiency: Steel manufacturing is an energy-intensive process. Therefore, it is essential to consider energy-efficient technologies and practices to reduce energy consumption and minimize greenhouse gas emissions. This can include the use of energy-efficient equipment, waste heat recovery systems, and energy management strategies. 6. Maintenance and Accessibility: The design of the plant should take into account ease of maintenance and accessibility for workers. Sufficient space should be provided for regular maintenance activities and easy access to equipment for repairs or replacements. 7. Scalability and Flexibility: Steel manufacturing plants should be designed with future expansion and changes in mind. The layout and infrastructure should allow for easy scalability and flexibility to accommodate changes in production capacity, product types, or technology upgrades. 8. Regulatory Compliance: Steel manufacturing plants must comply with various regulations and standards related to safety, environmental impact, emissions, and labor practices. The design should incorporate these regulations and ensure that the plant operates within legal boundaries. By considering these design considerations, steel manufacturing plants can be efficiently and safely designed, ensuring optimal production capacity, minimal environmental impact, and compliance with regulations.

- Q: Ask the two grouting steel structure column anchor bolts for what?

- But mainly by the anchor bolts to stress. The steel column base connection is hinged and rigid, rigid two pouring pouring depth 100mm, pouring depth two time pouring hinged 50mm in steel structure regulation on the stress problem. Of course I saw just according to make a person views.

- Q: How are steel structures designed for efficient waste management systems?

- Steel structures are designed for efficient waste management systems by incorporating features such as proper spacing for waste storage, durable materials to withstand heavy loads, and flexible layouts to accommodate different waste disposal processes. Additionally, steel structures can be easily modified or expanded to adapt to changing waste management needs, ensuring long-term efficiency and sustainability.

- Q: How are steel structures designed to accommodate architectural finishes and cladding?

- Steel structures are designed to accommodate architectural finishes and cladding by incorporating specific features and design considerations. These include the use of attachment points, support systems, and framing techniques that allow for the secure installation of various finishes and cladding materials. Additionally, engineering calculations and load analysis are conducted to ensure that the steel structure can safely support the weight and forces imposed by the finishes and cladding.

- Q: How are steel airports and terminals constructed?

- Steel airports and terminals are typically constructed using a combination of pre-engineered steel structures and traditional construction methods. The process involves designing and fabricating steel components off-site, which are then transported and assembled on-site. This approach ensures faster construction timelines, cost-effectiveness, and versatility in design. The steel framework provides strength and durability to support the airport or terminal's structure, while other materials such as glass, concrete, and insulation are used for walls, flooring, and other functional elements. Engineering expertise, careful planning, and coordination among various stakeholders are essential to successfully construct steel airports and terminals.

Send your message to us

First-class Steel-work Construction

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords