High-end Steel-work with Good Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Structure

Description:

1.Length of the welding withnot indication, full welding should be applied

2.Seam without indication is fillet weld, height is 0.75t

3.The cutting angle without indication, radius R=30

4.Cutting angle not specified should be

5.The diameter of the hole for the bolt if not specified, D=22

Project Reference:

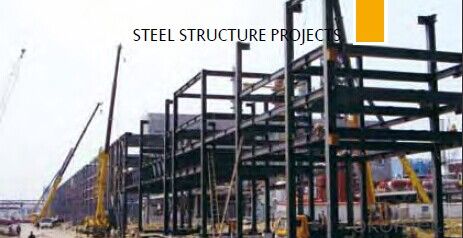

For the Steel structure project of Upper part of external

piperack for air separation and gasifying facilities of

460,000 tons MTO (Methanol to Olefins) project in

Duolun, we provide about 4,500 tons steel structure. It

is a heavy chemical indusry of national energy project.

- Q: What factors affect the cost of a steel structure?

- Several factors can affect the cost of a steel structure. These include the size and complexity of the structure, the type and quality of steel used, the location and accessibility of the construction site, the availability and cost of labor, as well as any additional features or customization required. Other factors such as market conditions, transportation costs, and regulatory requirements may also influence the overall cost of a steel structure.

- Q: How are steel structures inspected for quality control?

- Steel structures are inspected for quality control through various methods such as visual inspections, non-destructive testing techniques (such as ultrasonic testing or magnetic particle inspection), and structural load testing. These inspections ensure that the steel structures meet the required safety and quality standards, identifying any defects or flaws that may compromise the integrity of the structure.

- Q: How are steel structures used in educational institutions?

- Steel structures are widely used in educational institutions for various purposes. One of the most common applications is the construction of large and spacious buildings such as gymnasiums and auditoriums. Steel's high strength-to-weight ratio allows for large clear spans, eliminating the need for intermediate columns or supports, thus creating open and flexible spaces that can accommodate a large number of people. Additionally, steel structures are used for the construction of classrooms and laboratories. Steel frames provide a durable and long-lasting solution that can withstand heavy loads and extreme weather conditions. Moreover, their flexibility allows for easy modifications and expansions, which is particularly important in educational institutions that often need to adapt to changing requirements and enrollments. Another important use of steel in educational institutions is for the construction of libraries and storage facilities. Steel shelving systems are highly efficient in maximizing storage space and organizing books, documents, and other educational materials. The durability of steel ensures the safety of the stored items and reduces the maintenance costs associated with traditional wooden shelving. Furthermore, steel structures are used for the construction of sports facilities such as indoor arenas and outdoor stadiums. The inherent strength of steel enables the construction of large and robust structures that can accommodate various sporting events and activities. These facilities provide students with opportunities for physical education and extracurricular activities, promoting a healthy and active lifestyle. In summary, steel structures play a crucial role in educational institutions by providing durable, flexible, and cost-effective solutions for various construction needs. From classrooms and laboratories to gymnasiums and libraries, steel offers the strength, versatility, and efficiency required to support the educational environment and enhance the overall learning experience.

- Q: How are steel structures used in airports and terminals?

- Steel structures are extensively used in airports and terminals for various purposes. One key application of steel structures is in the construction of the terminal building itself. Steel frames are commonly used to create large open spaces, allowing for flexible interior layouts and accommodating the high volume of passengers and baggage flow. Steel structures are also utilized in the construction of hangars and maintenance facilities at airports. These structures provide the necessary strength and durability to house and maintain aircraft. The clear span capabilities of steel allow for large column-free spaces, accommodating even the largest commercial aircraft. In addition, steel is frequently used in the construction of boarding bridges, also known as jet bridges or passenger boarding bridges. These enclosed walkways connect the terminal building to the aircraft, providing a safe and convenient means for passengers to embark and disembark. Steel structures are ideal for this application due to their high load-bearing capacity and ability to withstand harsh weather conditions. Another important use of steel structures in airports is in the construction of baggage handling systems. These systems are responsible for efficiently transporting passenger luggage throughout the terminal. Steel conveyor systems and support structures are used to create the necessary infrastructure for baggage handling, ensuring smooth and timely delivery of luggage to and from aircraft. Furthermore, steel is commonly used in the construction of air traffic control towers. These towers provide a vantage point for air traffic controllers to monitor and direct air traffic. Steel structures offer the necessary stability and safety required for these elevated structures. Overall, steel structures play a vital role in the construction of airports and terminals. They provide the necessary strength, durability, and flexibility to accommodate the high volume of passengers, aircraft, and baggage flow. Whether it is in the terminal building, hangars, boarding bridges, baggage handling systems, or air traffic control towers, steel structures are indispensable in ensuring the efficient and safe operation of airports and terminals.

- Q: What are the design considerations for steel structures in mining or industrial settings?

- There are several important design considerations for steel structures in mining or industrial settings. First and foremost, the structures need to be able to withstand the harsh and demanding conditions often present in these environments, such as heavy loads, vibrations, and corrosion. Additionally, the design should take into account the specific needs and requirements of the mining or industrial operations, including the layout, accessibility, and functionality of the structure. Fire safety and hazard prevention should also be considered, along with the potential for expansion or modification in the future. Overall, the design of steel structures in mining or industrial settings should prioritize durability, safety, and efficiency.

- Q: What are the main steel structures in the steel structure and which are the secondary steel structures?

- You've split the question for me! Why don't you know?!! The main structure is the component that carries the main load. The same as the frame structure construction, (beam, column and slab is the main component), steel structure without transfer plate force, then only the beam column is the main component, such as roof frame, purlin, beam, sub beam, column. Then the members without any force are secondary members, such as steel drains, windproof rails, and ladders.

- Q: What are the considerations for designing steel bridges for pedestrians and cyclists?

- When designing steel bridges for pedestrians and cyclists, several considerations need to be taken into account. Firstly, the bridge should be wide enough to accommodate both pedestrians and cyclists comfortably. This means considering the width of the path and the clearance between the railing and the path. Secondly, the bridge should be designed with accessibility in mind. It should have ramps or elevators to ensure that people with disabilities can easily access and navigate the bridge. Additionally, the bridge should be designed to provide a safe and secure environment for pedestrians and cyclists. This may involve incorporating features such as barriers or railings to prevent accidents and falls, as well as proper lighting to ensure visibility during nighttime. Lastly, the design of the steel bridge should consider the aesthetic aspect, as it will be a prominent structure in the surrounding environment. Harmonizing the design with the surrounding landscape or incorporating architectural elements can enhance the overall visual appeal of the bridge. Overall, the considerations for designing steel bridges for pedestrians and cyclists revolve around ensuring safety, accessibility, functionality, and aesthetic appeal.

- Q: What are the different types of steel facade systems used in structures?

- Structures commonly utilize various types of steel facade systems, which not only enhance a building's aesthetic appeal but also offer structural support and protection. Some of the popular steel facade systems are as follows: 1. Curtain Wall Systems: These systems comprise lightweight aluminum or steel frames that are affixed to the building's structure. These frames are then covered with glass, metal, or other materials. Curtain wall systems are versatile and can be tailored to suit different architectural styles. 2. Rainscreen Systems: Designed to guard against moisture while permitting natural ventilation, rainscreen systems consist of an outer cladding layer made of steel, aluminum, or composite materials, and an inner layer that acts as a drainage plane. By preventing water infiltration, rainscreen systems uphold the building envelope's integrity. 3. Louver Systems: Louver systems regulate the amount of sunlight and airflow entering a building. These systems feature adjustable horizontal or vertical steel slats that can control the passage of light and air. Louver systems are commonly employed in commercial buildings to enhance energy efficiency and create a comfortable indoor environment. 4. Metal Mesh Systems: Metal mesh systems employ interwoven metal wires or expanded metal sheets to create a partially transparent screen. These systems find application in sun shading, privacy screening, and decorative purposes. Metal mesh systems can be customized with stainless steel, aluminum, or other metals to produce unique design patterns. 5. Steel Cladding Systems: Steel cladding systems involve directly attaching steel panels to the building's structure. These panels are typically constructed from galvanized or stainless steel and provide a robust and weather-resistant exterior finish. Due to their durability, longevity, and minimal maintenance requirements, steel cladding systems are widely used in industrial and commercial buildings. In summary, the selection of a steel facade system depends on factors such as the building's design, purpose, and location. Each system offers distinct advantages and can be customized to meet specific project requirements.

- Q: Measures to prevent rust in welded seam of steel structure

- 95% pure zinc protective film can effectively resist rust and corrosion, providing years of rust protectionBecause of the strong permeability, after the protective film has been scraped, the zinc can protect the metal from corrosionRepairing damaged metal surface is effective, used for welding seam repair.

- Q: How are steel structures designed for mining and extraction facilities?

- Steel structures for mining and extraction facilities are designed using a combination of engineering principles and specific industry requirements. These structures are designed to withstand the harsh operating conditions, heavy loads, and potential hazards associated with mining and extraction operations. Factors such as site location, geological conditions, equipment requirements, and safety regulations are taken into account during the design process. The design involves careful analysis and calculations to ensure the structural integrity, stability, and durability of the steel structures to support the safe and efficient operation of mining and extraction facilities.

Send your message to us

High-end Steel-work with Good Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords