Steel Structure with Good Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

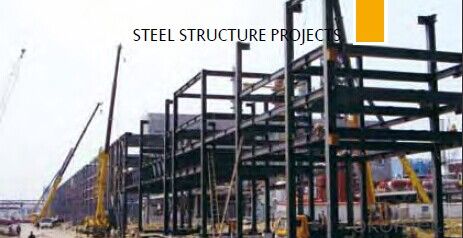

Steel Structure

Description:

1.Length of the welding withnot indication, full welding should be applied

2.Seam without indication is fillet weld, height is 0.75t

3.The cutting angle without indication, radius R=30

4.Cutting angle not specified should be

5.The diameter of the hole for the bolt if not specified, D=22

Project Reference:

For the Steel structure project of Upper part of external

piperack for air separation and gasifying facilities of

460,000 tons MTO (Methanol to Olefins) project in

Duolun, we provide about 4,500 tons steel structure. It

is a heavy chemical indusry of national energy project.

- Q: How are steel structures used in the construction of cultural institutions?

- Steel structures are commonly used in the construction of cultural institutions due to their strength, durability, and versatility. They provide the necessary structural support to create large open spaces, allowing for the design and construction of iconic architectural features. The use of steel frames and beams enables the creation of grand entrances, expansive exhibition halls, and soaring atriums, while also accommodating complex lighting systems and audiovisual equipment. Additionally, steel structures can be prefabricated off-site, speeding up the construction process and minimizing disruption to the surrounding area. Overall, steel plays a crucial role in the construction of cultural institutions by providing the necessary framework to showcase art, history, and cultural heritage in a visually stunning and functional manner.

- Q: How are steel structures used in the construction of oil and gas refineries?

- Steel structures are extensively used in the construction of oil and gas refineries due to their durability, strength, and versatility. They are utilized in various aspects of refinery construction, including the assembly of storage tanks, piping systems, processing units, and support structures. Steel's high load-bearing capacity allows for the construction of large storage tanks, while its resistance to corrosion ensures longevity in harsh refinery environments. Additionally, steel structures can be easily fabricated, erected, and modified, making them ideal for the dynamic requirements of refineries.

- Q: How do steel structures withstand seismic forces?

- Steel structures are able to withstand seismic forces due to their inherent strength and ductility. The flexibility of steel allows it to absorb and distribute the energy generated during an earthquake, reducing the impact on the structure. Additionally, steel's high strength-to-weight ratio enables the construction of lighter yet robust structures that can better resist the lateral forces caused by seismic activity.

- Q: What are the different types of steel stairs in a structure?

- There are several types of steel stairs commonly used in structures, including straight stairs, spiral stairs, and cantilever stairs. Straight stairs are the most basic and common type, consisting of a straight flight of steps. Spiral stairs are compact and provide a space-saving solution, wrapping around a central pole. Cantilever stairs are a more architectural choice, featuring floating steps supported by a single stringer or hidden structure. Other variations include L-shaped and U-shaped stairs, which are designed to fit specific structural and spatial requirements.

- Q: How are steel structures designed to accommodate electrical and data systems?

- Efficient and safe integration of electrical and data systems is a key consideration in the design of steel structures. Collaboration between structural engineers, electrical engineers, and data system specialists is typically involved in the design process. To facilitate electrical systems, the steel structure is designed to incorporate conduits, cable trays, and junction boxes. These components are strategically positioned throughout the structure to create pathways for electrical wiring, ensuring that power can be supplied to desired locations. The conduits and cable trays are typically concealed within the structure, hidden within walls, ceilings, or floors to maintain an aesthetically pleasing appearance. In addition to electrical systems, the design process also takes into account the requirements of data systems. Steel structures are designed with the necessary infrastructure to support data cabling, such as network cables and fiber optic cables. Similar to electrical conduits, these data cables are routed through the structure using conduits or cable trays, providing protection and organization. Special attention is given to the placement of data outlets, network switches, and server rooms to optimize connectivity and data flow throughout the structure. To ensure the safe operation of electrical and data systems, steel structures are also designed with grounding systems, surge protection devices, and proper ventilation for equipment rooms. These measures help prevent electrical malfunctions, safeguard sensitive electronic equipment, and maintain an ideal environment for optimal system performance. Overall, the design of steel structures carefully considers the specific requirements of electrical and data systems, creating a framework that supports the integration and operation of these systems. By meticulously planning and incorporating the necessary infrastructure, steel structures can effectively accommodate the electrical and data needs of buildings, providing a safe and efficient environment for occupants.

- Q: How are steel structures used in theme parks and entertainment venues?

- Steel structures are commonly used in theme parks and entertainment venues due to their durability, strength, and design flexibility. They are utilized in the construction of roller coasters, water slides, observation towers, and other thrilling rides. Steel provides the necessary support and stability to ensure the safety of these structures, allowing for the creation of large-scale and intricate attractions that can withstand the forces experienced in amusement parks. Additionally, steel structures are often used for the construction of entertainment venues such as stadiums and concert halls, providing ample space and structural integrity for hosting large crowds and supporting impressive stage designs.

- Q: What are the design considerations for steel hangars?

- When it comes to designing steel hangars, several important factors must be taken into account. These considerations include: 1. Maintaining Structural Integrity: It is crucial that steel hangars are designed to withstand various loads and forces, such as wind, snow, and seismic loads. The structural frame should be able to support not only the weight of the hangar itself but also any aircraft or equipment that will be stored inside. 2. Accommodating Clear Spans: Typically, hangars require large clear spans to accommodate the wingspan of aircraft. Designing for clear spans helps maximize the usable space within the hangar and allows for efficient movement of aircraft. 3. Ensuring Effective Door Systems: Hangars necessitate large doors to enable aircraft to enter and exit. The design of the door system is vital to ensure smooth operation, weather protection, and security. The door should be able to withstand wind loads and provide sufficient clearance for aircraft to pass through. 4. Prioritizing Fire Safety: Fire safety should be a primary concern when designing steel hangars. Incorporating fire resistance measures, such as fire-rated walls and fire suppression systems, into the design helps protect both the hangar and the aircraft stored within. 5. Addressing HVAC and Ventilation Needs: Proper heating, ventilation, and air conditioning (HVAC) systems are often necessary in hangars to maintain appropriate temperature and humidity levels. Designing an efficient HVAC system is essential to ensure the comfort of personnel working in the hangar and to protect the aircraft from extreme weather conditions. 6. Providing Adequate Lighting: Sufficient lighting is critical for safety and functionality within the hangar. The design should incorporate appropriate lighting fixtures and layouts to ensure there is ample illumination for maintenance, inspections, and aircraft movement. 7. Considering Access and Circulation: Efficient access and circulation within the hangar should be taken into account during the design process. This involves designing suitable walkways, ramps, and staircases for personnel to move around the hangar safely and easily. Additionally, provisions for vehicle access, such as trucks or carts, should be considered. 8. Addressing Environmental Concerns: Designing with sustainability and energy efficiency in mind is increasingly important in construction. Implementing eco-friendly features, such as energy-efficient lighting, insulation, and renewable energy sources, can help minimize the environmental impact of the hangar. Overall, the design considerations for steel hangars revolve around ensuring structural integrity, functionality, safety, and efficiency. By addressing these considerations, designers can create hangars that provide a secure and optimal environment for aircraft storage and maintenance.

- Q: What are the different types of steel stairs and railings used in structures?

- There are several different types of steel stairs and railings that are commonly used in various structures. These include: 1. Straight stairs: Straight stairs are the most basic and common type of staircase found in structures. They consist of a straight flight of stairs that connects two levels without any turns or curves. 2. L-shaped stairs: L-shaped stairs, also known as quarter-turn stairs, are designed to change direction at a landing. They are commonly used when space is limited or when there is a need to change the direction of the staircase. 3. U-shaped stairs: U-shaped stairs, also known as half-turn or switchback stairs, consist of two parallel flights of stairs that change direction at a landing, forming a U-shape. They are often used in larger structures where space is not a constraint. 4. Spiral stairs: Spiral stairs are a compact and visually appealing option that consists of a central column with steps spiraling around it. They are commonly used in structures with limited space or as a decorative feature. 5. Cantilevered stairs: Cantilevered stairs are a modern and minimalist design that gives the illusion of floating stairs. They are supported by a hidden structure, usually a wall or a beam, and do not require visible support underneath. 6. Glass railings: Glass railings are a popular choice for modern structures as they provide an unobstructed view and a sleek, contemporary look. They are often used in combination with steel frames or posts for added strength and stability. 7. Cable railings: Cable railings consist of horizontal or vertical cables that are tensioned between steel posts. They offer a sleek and minimalist appearance and are commonly used in contemporary structures or areas where visibility is important, such as balconies or outdoor decks. 8. Pipe railings: Pipe railings are made of steel pipes and are commonly used in industrial or commercial structures. They are durable, easy to install, and provide a sturdy and functional railing option. Overall, the choice of steel stairs and railings depends on the specific requirements of the structure, architectural design, and personal preferences. Different types of steel stairs and railings offer a range of options in terms of functionality, aesthetics, and space utilization.

- Q: How are steel structures designed for military and defense facilities?

- Careful planning and engineering are required when designing steel structures for military and defense facilities to meet specific requirements and ensure high levels of safety and functionality. These facilities serve critical purposes, including housing military personnel, storing equipment and weapons, and functioning as command centers, necessitating robust and efficient design. The design process for military and defense steel structures consists of several key steps. Firstly, the facility's specific needs and objectives are identified, determining the structure's size, layout, purpose, and any unique requirements based on the nature of military operations or defense functions. Once the requirements are established, structural engineers work on creating a design capable of withstanding the demanding conditions typically encountered in military and defense operations. Factors such as extreme weather events, seismic activity, blast resistance, and projectile impacts are taken into consideration. Steel is often the preferred material for these structures due to its strength, durability, and versatility. Steel frames can easily handle heavy loads and provide necessary resistance against various forces. Features like reinforced walls, blast-resistant windows, and roof systems designed to mitigate damage from explosions or attacks are typically included in the design. To ensure structural integrity and safety, advanced computer-aided design (CAD) software and structural analysis tools are utilized. These tools allow engineers to simulate and analyze different scenarios, optimizing the design for maximum performance and safety. Additionally, military and defense facilities must adhere to specific building codes and regulations regarding security, fire protection, and accessibility. These regulations ensure that the structures are secure, functional, and meet necessary safety standards. In conclusion, the meticulous design process for steel structures in military and defense facilities considers their specific requirements. By utilizing steel's strength and durability, along with advanced design tools, engineers can create structures capable of withstanding the unique challenges faced in military and defense operations.

- Q: What are the advantages of using steel structures in the oil and gas industry?

- There are several advantages of using steel structures in the oil and gas industry. Firstly, steel is a highly durable material that can withstand extreme weather conditions and harsh environments, making it ideal for offshore and onshore installations. Secondly, steel structures are highly resistant to corrosion, which is essential in an industry where exposure to moisture and chemicals is common. Additionally, steel offers excellent strength-to-weight ratio, allowing for the construction of large and complex structures that can support heavy equipment and withstand high loads. Furthermore, steel structures are easy to fabricate, transport, and assemble, resulting in cost and time savings during construction. Lastly, steel is a sustainable material that can be recycled, reducing the industry's environmental impact and promoting a circular economy. Overall, the use of steel structures in the oil and gas industry provides durability, corrosion resistance, strength, efficiency, and environmental benefits.

Send your message to us

Steel Structure with Good Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords