First-class Steel-work

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Structure

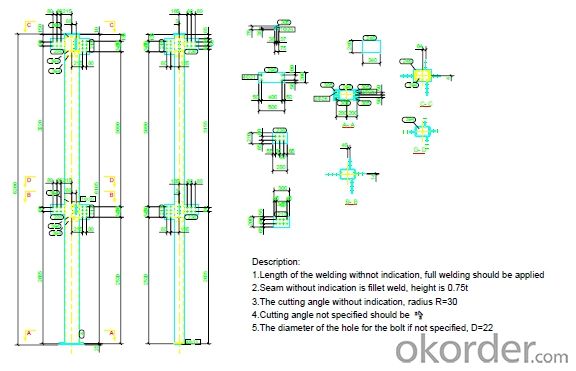

Description:

1.Length of the welding withnot indication,full welding should be applied

2.Seam without indication is fillet weld,height is 0.75t

3.The cutting angle without indication,radius R=30

4.Cutting angle not specified should be 20/20

5.The diameter of the hole for the bolt if not specified, D=22

Project Reference:

Inner Mongolia Shangdu Power Plant is the main source

of west-east power transmission project with total

incestment of 5137 million Yuan. 1,900 tons for the steel

structure of the project with maximum thickness 60mm-

75mm.

- Q: How is steel used in agricultural structures?

- Steel is used in agricultural structures for its strength and durability. It is commonly used to construct buildings such as barns, storage facilities, and animal shelters. Steel provides a reliable framework that can withstand heavy loads, harsh weather conditions, and the wear and tear associated with farming activities. Additionally, steel is often used in roofing and fencing materials, providing long-lasting protection for crops, livestock, and equipment.

- Q: How are steel structures used in the construction of observatories?

- Observatories often use steel structures because they are incredibly strong, durable, and versatile. Steel ensures the structural integrity needed to support the observatory's equipment, including telescopes, domes, and scientific instruments. One notable advantage of steel structures is their ability to withstand extreme weather conditions. Many observatories are situated in remote and harsh environments, like mountaintops, where they face strong winds, heavy snow loads, and seismic activity. Steel's high tensile strength and corrosion resistance make it the perfect material for enduring these challenging conditions, ensuring the observatory's safety and stability. Steel structures also allow for spacious areas to accommodate telescopes and equipment. The use of steel beams and columns creates unobstructed views of the sky, minimizing interference with observatory operations. This is crucial for capturing top-quality astronomical data. Moreover, steel structures are highly flexible and can be easily modified or expanded as the observatory's needs change over time. This is especially important for observatories engaged in ongoing research or technological advancements, as they may need to upgrade or replace equipment periodically. Steel structures enable seamless integration of new equipment or expansion without compromising structural integrity. Furthermore, steel is an environmentally friendly and sustainable material. It can be completely recycled, reducing the observatory's carbon footprint during construction. Steel structures also require less maintenance compared to other materials, reducing long-term costs and ensuring the observatory's longevity. In conclusion, steel structures are essential in observatory construction due to their strength, durability, and versatility in supporting equipment and withstanding challenging environmental conditions. Their flexibility, sustainability, and low maintenance requirements make them an ideal choice for observatories requiring long-term reliability and adaptability.

- Q: How do steel structures contribute to the overall energy efficiency of a building?

- Steel structures contribute to the overall energy efficiency of a building in several ways. Firstly, steel is a lightweight material that allows for longer spans and open floor plans, reducing the need for additional columns and supports which can obstruct natural light and airflow. Secondly, steel has high thermal conductivity, meaning it can efficiently transfer heat or cold throughout the building, reducing the energy required for heating and cooling. Additionally, steel is a highly durable and long-lasting material, requiring minimal maintenance and reducing the need for energy-consuming repairs or replacements. Overall, steel structures contribute to energy efficiency by optimizing natural resources, improving insulation, and minimizing energy consumption for a sustainable and eco-friendly building.

- Q: What are the considerations for designing steel structures in areas with high wind loads?

- When designing steel structures in areas with high wind loads, several considerations need to be taken into account. Firstly, the design should meet the local building codes and standards specific to wind loads. The structure should be designed to withstand the maximum wind speeds expected in the area, taking into consideration factors such as the topography and surrounding buildings. Secondly, the shape and profile of the structure should be carefully considered. Aerodynamic shapes, such as streamlined or tapered designs, can help reduce wind resistance and minimize the impact of wind loads on the structure. Additionally, the orientation of the structure and its openings, such as doors and windows, should be strategically planned to minimize the effects of wind pressure. Another important consideration is the selection of appropriate materials and connections. High-strength steel should be used to ensure the structural integrity and resistance against wind-induced forces. Connections between steel members should be designed for maximum strength and rigidity to withstand wind loads. Additionally, the use of bracing systems, such as diagonal or cross-bracing, can enhance the overall stability and reduce the vulnerability of the structure to wind loads. Lastly, regular maintenance and inspection of the steel structure are crucial to ensure its continued performance and safety in high wind load areas. Periodic checks should be carried out to identify any signs of structural damage or degradation, allowing timely repairs or reinforcements to be implemented if necessary.

- Q: What are the design considerations for steel sports facilities?

- There are several important design considerations to take into account when designing steel sports facilities. These considerations include structural integrity, durability, flexibility, aesthetics, and sustainability. Firstly, structural integrity is crucial to ensure the safety and stability of the facility. Steel offers high strength-to-weight ratio, making it an ideal material choice for large-scale sports facilities. The design must take into account factors such as wind and seismic loads, as well as the potential for heavy equipment and crowds. Durability is another key consideration. Sports facilities are subject to high levels of wear and tear due to constant use and exposure to various weather conditions. Steel is known for its resistance to corrosion, rust, and deterioration, providing a long-lasting solution for sports facilities. Proper protective coatings and maintenance plans should be implemented to enhance the durability of the steel structure. Flexibility is important to accommodate different sports and events that may take place in the facility. Steel structures can be easily customized and modified without compromising their integrity. This allows for easy reconfiguration of spaces, addition of new features, or expansion of the facility to meet changing needs. Aesthetics play a significant role in attracting spectators and creating a visually appealing environment. Steel structures offer design flexibility, allowing architects to create unique and eye-catching sports facilities. The use of steel can also provide open and column-free spaces, enhancing sightlines and creating a better experience for spectators. Lastly, sustainability is becoming increasingly important in the design of sports facilities. Steel is a highly sustainable material as it is 100% recyclable and has a low carbon footprint. Using steel in sports facility design can contribute to LEED certification and other sustainability goals. Incorporating energy-efficient systems, such as natural lighting and HVAC systems, can further enhance the sustainability of the facility. In conclusion, the design considerations for steel sports facilities encompass structural integrity, durability, flexibility, aesthetics, and sustainability. By carefully addressing these factors, architects and engineers can create safe, functional, visually appealing, and sustainable sports facilities that can withstand the demands of various sports and events.

- Q: How are steel structures designed for long spans?

- Steel structures are designed for long spans by incorporating various design considerations such as selecting appropriate structural systems, utilizing advanced analysis techniques, and optimizing the use of steel materials. The design process involves determining the loads and forces acting on the structure, evaluating the structural behavior under different conditions, and ensuring structural stability and safety. Additionally, engineers may employ techniques like truss systems, arches, or suspension structures to efficiently distribute the loads and achieve longer spans without compromising the structural integrity.

- Q: How are steel structures used in the construction of mining facilities?

- Due to their strength, durability, and versatility, steel structures are extensively utilized in mining facilities. These structures play a pivotal role in supporting the heavy machinery and equipment needed for mining operations. One significant application of steel structures in mining facilities involves creating the framework for various buildings and structures. This encompasses processing plants, storage facilities, workshops, and administration buildings. The high strength-to-weight ratio of steel permits the construction of spacious areas without the requirement of excessive supporting columns or walls, allowing for flexibility in facility layout and design. Conveyor systems, which are crucial for efficient mining operations, also rely on steel structures. These systems transport materials such as ore, coal, and minerals over long distances, and steel structures provide support and guidance for the conveyors. The strength of steel ensures that the structures can withstand the weight and pressure of the transported materials. Furthermore, steel structures are employed in the construction of mining equipment and machinery. Components like frames, chassis, and supports are often made from steel due to its strength and ability to endure heavy loads. Additionally, steel's resistance to corrosion makes it suitable for mining environments where exposure to moisture and chemicals is common. Safety is of utmost importance in mining facilities. Steel structures offer a high level of structural integrity, guaranteeing the safety of workers and equipment. Steel is fire-resistant and can withstand extreme weather conditions, making it a reliable choice for mining facilities situated in areas prone to wildfires or severe storms. Overall, the utilization of steel structures in the construction of mining facilities brings forth numerous advantages. From providing robust and long-lasting frameworks for buildings and equipment to enhancing safety and design flexibility, steel plays a critical role in supporting the infrastructure of the mining industry.

- Q: How is steel manufactured for use in construction?

- Steel is manufactured for use in construction through a process called steelmaking, which involves the conversion of iron ore into steel. The primary method used is the basic oxygen furnace (BOF), where iron ore, along with other materials like coal and limestone, is melted in a furnace to remove impurities. This molten iron is then combined with recycled steel and alloying elements to control its properties. The resulting steel is then cast into various shapes, such as beams or plates, and undergoes further treatments like heat treatment or galvanization before being used in construction.

- Q: How does the design of a steel structure affect its stability?

- The design of a steel structure greatly influences its stability. Factors such as the type of connections, bracing systems, and the overall structural layout can impact the structure's ability to resist various loads and forces. A well-designed steel structure will consider factors like load distribution, wind and seismic resistance, and the efficient transfer of loads to the foundation. Adequate bracing and connections ensure that the structure can withstand external forces and prevent collapse or deformation. Therefore, a carefully planned design is crucial for ensuring the stability and overall structural integrity of a steel structure.

- Q: How are steel structures designed for thermal comfort?

- Various strategies can be employed to achieve thermal comfort in steel structures, aiming to regulate internal temperature and enhance occupants' comfort. Insulation is a key consideration, as effective insulation materials incorporated into the walls, roofs, and floors of steel structures can minimize heat transfer, reducing heat gain or loss from the external environment. This insulation helps maintain a stable internal temperature, minimizing the need for excessive heating or cooling. Efficient HVAC systems are another aspect of thermal comfort design for steel structures. These systems can be tailored to provide adequate heating or cooling based on the specific requirements of the building and its occupants. By ensuring proper airflow and temperature control, occupants can enjoy a comfortable indoor environment throughout the year. The orientation and placement of windows and shading devices are also important design considerations. By strategically positioning windows to maximize natural light while minimizing direct sunlight exposure, passive solar heating can be utilized to provide additional warmth during colder months. Shading devices like blinds or overhangs can also help prevent solar heat gain during warmer months, preventing overheating. The selection of appropriate building materials plays a crucial role in steel structure design for thermal comfort. For example, using high-performance glazing with low solar heat gain coefficients can help reduce unwanted heat transfer. Additionally, incorporating thermal mass materials like concrete or stone in the building envelope can regulate temperature fluctuations by absorbing and releasing heat gradually. Lastly, advanced technologies such as smart controls and energy management systems can optimize energy consumption and enhance thermal comfort. These systems can monitor and adjust temperature, humidity, and ventilation levels based on occupancy patterns and weather conditions, ensuring a comfortable and energy-efficient indoor environment. In conclusion, achieving thermal comfort in steel structures involves implementing insulation, efficient HVAC systems, strategic window placement, shading devices, appropriate building materials, and advanced technologies. Architects and engineers can create steel structures that promote a comfortable and sustainable living or working environment by considering these factors.

Send your message to us

First-class Steel-work

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords