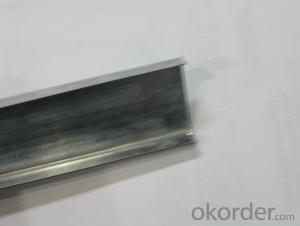

Galvanized cowl

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Diameter: Φ 100mm Φ 125mm Φ 160mm Φ 200mm Φ 250mm

We are one of the biggest and professinal manufacturer of ventilation products including INLINE FANS, SPEED CONTROLLER, CARBON FILTER, PIPE FITTING, etc in China. We can provide you with high quality & competitive price & excellent service. Welcome to visit our Group Company at any time.

Model NO.:150mm

Material:Metal

Type:Centrifugal Fan

Certification:ISO, SGS

Electric Current Type:No Power

Mounting:The Chimney, The Tube, and The Roof

Blade Material:Stainless Steel

No Maintenance or Operating Costs:Water and Dust Proof

Improves Air Quality:Improves Productivity

Material: Stainless Steel, Color Coated:Type: 100mm/120mm/125mm/150mm/250mm/300mm

Delivery Time:Very Fast, Within 10 Days

Export Markets:Global

Trademark:WT

Packing:Box

Standard:The international standard

Origin:China

HS Code:84148090

Production Capacity:100000PCS/Per Month

1. Material: Stainless steel (SS201, SS304), Color steel, Aluminum, Galvanized steel.

Usually: Stainless steel, color steel. Please you choose according your requests. We can produce.

2. Type/size: 100MM/125MM/300MM/350MM/400MM/420MM/450MM/500MM/560MM/600MM/680MM/760MM/800MM/900MM/1000MM/1200MM.

Usually: 100mm/120mm/125mm/150mm/250mm/300mm/350mm/450mm/500mm/600mm/680mm/900mm/1000mm/1200mm.

We can according your requests to produce.

3. Products advantage:

1). No maintenance or operating costs

2). Water and dust proof

3). Improves air quality

4). Improves productivity

4. The more information of products:

1). The structure of the high quality,

2). The precision of the running device,

3). Green environmental protection ventilation equipment,

4). Applicability widely. All kinds of industrial factory building contour plate light steel structure roofing, concrete roof can also be installed.

- Q: How are steel structures used in the construction of transmission towers?

- Steel structures are commonly used in the construction of transmission towers due to their strength, durability, and cost-effectiveness. Steel provides the necessary structural support to withstand the weight of the transmission lines and other equipment. It also offers flexibility in design, allowing for various tower heights and configurations. Moreover, steel's resistance to corrosion ensures the longevity of the transmission tower, reducing maintenance needs and ensuring reliable power transmission.

- Q: What are the typical design considerations for steel food processing or manufacturing plants?

- Some typical design considerations for steel food processing or manufacturing plants include ensuring proper sanitation and hygiene practices, implementing efficient workflow and layout designs, incorporating adequate ventilation and temperature control systems, integrating proper waste management and disposal systems, and complying with relevant safety regulations and standards. Additionally, considerations may also include selecting the appropriate steel materials and finishes to prevent corrosion and contamination, optimizing energy usage and sustainability, incorporating space for future expansion or modifications, and designing for ease of maintenance and equipment access.

- Q: How are steel structures designed for high-rise buildings?

- Steel structures for high-rise buildings are designed using a systematic approach that takes into account various factors such as load calculations, materials selection, structural analysis, and safety considerations. The design process involves assessing the anticipated loads, such as dead loads, live loads, and environmental loads, and designing the steel framework to resist those loads effectively. The design also considers the architectural requirements, building codes, and standards to ensure structural stability, durability, and occupant safety. Advanced computer-aided design tools and engineering principles are employed to optimize the design, ensuring that the steel structure can withstand the forces and stresses imposed on it while providing a stable and efficient solution for high-rise buildings.

- Q: What are the factors to consider when designing steel structures for transportation infrastructure?

- When it comes to designing steel structures for transportation infrastructure, careful consideration must be given to several factors. These factors encompass: 1. Load capacity: It is crucial for the structure to withstand the expected loads and forces it will encounter over its lifespan. This includes the weight of vehicles, pedestrians, as well as additional loads like wind, seismic activity, or potential impacts. 2. Durability: Transportation infrastructure typically faces harsh environmental conditions, such as weathering, temperature fluctuations, and chemical exposure. To ensure long-term durability, the chosen steel must resist corrosion and other forms of deterioration. 3. Design life: The structure should align with the intended use and expected lifespan of the transportation infrastructure. This will determine the necessary maintenance and potential need for future modifications or expansions. 4. Safety: Safety is of utmost importance in transportation infrastructure. The design should consider factors like fire resistance, crashworthiness, and the ability to evacuate safely during emergencies. 5. Construction constraints: The construction process must be feasible and efficient. Site conditions, access for equipment and materials, and any potential restrictions or regulations impacting the construction process should be taken into account. 6. Aesthetics: Steel structures in transportation infrastructure play a significant role in the project's overall visual appearance. The design should consider architectural elements, such as shape, color, and texture, to ensure visual harmony with the surrounding environment. 7. Sustainability: The design should incorporate sustainable practices, considering the increasing focus on environmental responsibility. This may involve using recycled steel, energy-efficient designs, and the ability to dismantle or repurpose the structure easily at the end of its lifespan. 8. Cost-effectiveness: The overall cost of the steel structure, including construction, maintenance, and potential future modifications, should be considered. The design should aim to achieve the desired functionality and durability while minimizing unnecessary expenses. By accounting for these factors, designers can ensure that steel structures in transportation infrastructure are safe, durable, visually appealing, and cost-effective, ultimately contributing to the project's overall success and longevity.

- Q: What are the different types of steel bridges for railways?

- There are several types of steel bridges that are commonly used for railways, including truss bridges, beam bridges, arch bridges, and suspension bridges. Each type has its own unique design and structural characteristics that make it suitable for different types of railway applications.

- Q: What are the considerations for steel structures in areas with high winds?

- Some considerations for steel structures in areas with high winds include the need for proper design and engineering to ensure structural stability, the use of wind-resistant materials and construction techniques, the incorporation of wind load calculations and analysis during the design phase, and the implementation of measures to mitigate potential wind-induced damages such as bracing systems or windbreaks. It is also important to consider the local building codes and regulations specific to high wind areas, as well as conducting regular inspections and maintenance to ensure the continued integrity of the steel structure.

- Q: What are the typical design considerations for steel retail or commercial buildings?

- Some typical design considerations for steel retail or commercial buildings include structural stability, efficient use of space, flexibility for future modifications or expansions, adequate insulation and energy efficiency, proper ventilation and lighting, compliance with local building codes and regulations, aesthetic appeal, and cost-effectiveness.

- Q: What are the different types of steel healthcare facilities?

- There are several different types of steel healthcare facilities, including hospitals, clinics, nursing homes, rehabilitation centers, and medical research facilities.

- Q: What can be painted on the surface of steel structure to prevent rust and corrosion?

- Bridge steel structure (ordinary type): primer is epoxy zinc phosphate primer, intermediate paint is epoxy micaceous iron intermediate finish, acid polyurethane paint

- Q: How are steel airports and terminals constructed?

- Steel airports and terminals are typically constructed using a combination of pre-engineered steel structures and traditional construction methods. The process involves designing and fabricating steel components off-site, which are then transported and assembled on-site. This approach ensures faster construction timelines, cost-effectiveness, and versatility in design. The steel framework provides strength and durability to support the airport or terminal's structure, while other materials such as glass, concrete, and insulation are used for walls, flooring, and other functional elements. Engineering expertise, careful planning, and coordination among various stakeholders are essential to successfully construct steel airports and terminals.

Send your message to us

Galvanized cowl

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches