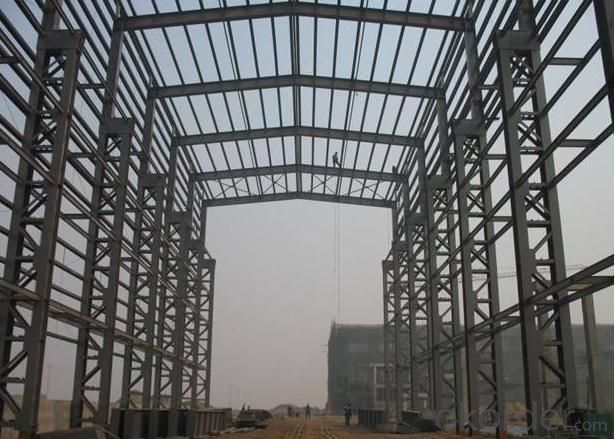

Heavy steel Workshop

- Loading Port:

- Tianjin Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 sqare meters m.t.

- Supply Capability:

- 50000 Square Meters/Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of heavy steel workshop

The project is smelting heavy steel workshop

Maximum crane: 100 tons

Single building area: 30,000 square meters

1. GB standard material

2. High Structural safety and reliability

3. The production can reach GB/JIS/ISO/ASME standard

Packaging & Delivery of heavy steel workshop

1. According to the project design and the component size, usually the main component parts are nude packing and shipped by bulk vessel. And the small parts are packed in box or suitable packages and shipped by containers.

2. This will be communicated and negotiated with buyer according to the design.

Engineering Design Software of heavy steel workshop

Tekla Structure \ AUTO CAD \ PKPM software etc

⊙Complex spatial structure project detailed design

⊙Construct 3D-model and structure analysis. ensure the accuracy of the workshop drawings

⊙Steel structure detail ,project management, automatic Shop Drawing, BOM table automatic generation system.

⊙Control the whole structure design process,we can obtain higher efficiency and better results

Technical support of heavy steel workshop

|

Worker |

Rate of frontline workers with certificate on duty reaches 100% |

|

Welder |

186 welders got AWS & ASME qualification 124 welders got JIS qualification 56 welders got DNV &BV qualification |

|

Technical inspector |

40 inspectors with UT 2 certificate 10 inspectors with RT 2 certificate 12 inspectors with MT 2 certificate 3 inspectors with UT3 certificate |

|

Engineer |

21 engineers with senior title 49 engineers with medium title 70 engineers with primary title. 61 First-Class Construction Engineers 182 Second-Class Construction Engineers |

|

International certification |

10 engineers with International Welding engineer, 8 engineers with CWI. |

Production Flow of heavy steel workshop

Material preparation—cutting—fitting up—welding—component correction—rust removal—paint coating—packing—to storage and transportation (each process has the relevant inspection)

steel structure cutting machine steel structure (H beam) fitting up machine steel structure welding machine steel structure painting area

Usage/Applications of steel structure/steel frame

*Characters of Structure Steel

1. Steel is characterized by high strength, light weight, good rigidity, strong deformation capacity, so it is suitable for construction of large-span, super high and super-heavy buildings particularly;

2. It with good homogeneous and isotropic, is an ideal elastomer which perfectly fits the application of general engineering;

3. The material has good ductility and toughness, so it can have large deformation and it can well withstand dynamic loads;

4. Steel structure’s construction period is short;

5. Steel structure has high degree of industrialization and can realize-specialized production with high level of mechanization.

*Steel structure application

1. Heavy industrial plants: relatively large span and column spacing; with a heavy duty crane or large-tonnage cranes; or plants with 2 to 3 layers cranes; as well as some high-temperature workshop should adopt steel crane beams, steel components, steel roof, steel columns, etc. up to the whole structure.

2. Large span structure: the greater the span of the structure, the more significant economic benefits will have by reducing the weight of the structure

3. Towering structures and high-rise buildings: the towering structure, including high-voltage transmission line towers, substation structure, radio and television emission towers and masts, etc. These structures are mainly exposed to the wind load. Besides of its light weight and easy installation, structure steel can bring upon with more economic returns by reducing the wind load through its high-strength and smaller member section.

4. Structure under dynamic loads: As steel with good dynamic performance and toughness, so it can be used directly to crane beam bearing a greater or larger span bridge crane

5. Removable and mobile structures: Structure Steel can also apply to movable Exhibition hall and prefabricated house etc by virtue of its light weight, bolt connection, easy installation and uninstallation. In case of construction machinery, it is a must to use structure steel so as to reduce the structural weight.

6. Containers and pipes: the high-pressure pipe and pipeline, gas tank and boiler are all made of steel for the sake of its high strength and leakproofness

7. Light steel structure: light steel structures and portal frame structure combined with single angle or thin-walled structural steel with the advantages of light weight, build fast and steel saving etc., in recent years has been widely used.

8. Other buildings: Transport Corridor, trestle and various pipeline support frame, as well as blast furnaces and boilers frameworks are usually made of steel structure.

All in all, according to thereality, structure steel is widely used for high, large, heavy and light construction.

- Q: How are steel structures designed to be resistant to corrosion?

- Steel structures are designed to be resistant to corrosion through a combination of material selection, coating application, and maintenance. Firstly, the choice of the right steel grade is crucial. Stainless steel, for example, contains a higher percentage of chromium which forms a protective oxide layer on the surface, preventing corrosion. Additionally, galvanized steel is often used, where a layer of zinc is applied to the steel surface to act as a sacrificial barrier against corrosion. Furthermore, proper coating application plays a vital role in protecting steel structures. Epoxy and polyurethane coatings are commonly used to create a physical barrier between the steel and the environment, preventing moisture and corrosive substances from reaching the surface. These coatings are applied in multiple layers to ensure maximum protection. Regular maintenance is also essential in ensuring the corrosion resistance of steel structures. This includes inspecting for any signs of damage or coating deterioration, and promptly addressing them. Regular cleaning, removing any accumulated dirt or debris, can also prevent corrosion by reducing the potential for moisture retention. In summary, steel structures are designed to be resistant to corrosion through the use of appropriate steel grades, protective coatings, and regular maintenance. These measures collectively help to extend the lifespan of steel structures and maintain their structural integrity.

- Q: How are steel structures designed to accommodate architectural finishes and cladding?

- Steel structures are designed to accommodate architectural finishes and cladding by incorporating specific features and design considerations. These include the use of attachment points, support systems, and framing techniques that allow for the secure installation of various finishes and cladding materials. Additionally, engineering calculations and load analysis are conducted to ensure that the steel structure can safely support the weight and forces imposed by the finishes and cladding.

- Q: How are steel structures designed to be resistant to vibrations?

- Steel structures are designed to be resistant to vibrations through various techniques and considerations. One important aspect is the selection of the appropriate steel materials with high strength and stiffness characteristics. This ensures that the structure can withstand dynamic loads and vibrations without undergoing excessive deformation. Structural engineers also take into account the overall design of the steel structure. By carefully considering the layout and arrangement of components, they can minimize the potential for resonant vibrations. Resonance occurs when the natural frequency of the structure matches the frequency of the external vibrations, leading to amplified oscillations. By avoiding resonance, the structure can better withstand vibrations. Additionally, engineers incorporate damping mechanisms into the design. Damping helps dissipate the energy generated by vibrations and reduces their amplitudes. This can be achieved through the use of damping materials or devices, such as rubber pads or tuned mass dampers. These elements absorb or dissipate the vibrational energy, preventing it from being transmitted throughout the structure. Furthermore, steel structures can be designed with increased stiffness, which helps to minimize vibrations. By enhancing the rigidity of the structure, engineers can reduce the potential for excessive deformation and oscillations. This can be achieved through the use of additional bracing, cross-members, or diagonal supports, which effectively increase the overall stiffness of the structure. Lastly, computer-aided design and analysis tools play a crucial role in designing steel structures resistant to vibrations. Engineers can simulate and analyze the dynamic behavior of the structure under various loading conditions, allowing them to identify potential vibration issues and make necessary adjustments to the design. Overall, a combination of material selection, careful design considerations, incorporation of damping mechanisms, increasing stiffness, and advanced analysis techniques are employed to ensure that steel structures are resistant to vibrations. These measures help to enhance the structural integrity and durability, ensuring the safety and functionality of the steel structure in the face of external vibrations.

- Q: What are the different types of steel stairs used in buildings?

- The different types of steel stairs used in buildings include straight stairs, spiral stairs, and helical stairs. Straight stairs are the most common and straightforward design, while spiral stairs have a circular shape and are often used in compact spaces. Helical stairs, on the other hand, have a curved shape and provide a more elegant and visually appealing option.

- Q: What are the factors that affect the cost of a steel structure?

- There are several factors that affect the cost of a steel structure. Some of the key factors include the size and complexity of the structure, the type and quality of steel used, the location and accessibility of the construction site, the labor and construction techniques employed, as well as any additional features, finishes, or customization required. Other factors such as market conditions, transportation costs, and project timeline may also influence the overall cost of a steel structure.

- Q: What are the considerations for designing steel communication towers?

- When it comes to designing steel communication towers, there are several important factors that need to be taken into account. These factors encompass: 1. Ensuring Structural Stability: It is crucial for steel communication towers to be engineered in a way that can withstand various environmental elements like wind, snow, ice, and seismic loads. This is particularly important in areas prone to extreme weather conditions, as the tower must be stable and avoid collapsing. 2. Determining Height and Loading Capacity: The tower's height is determined by the required coverage area and the type of communication equipment that will be installed. The tower should be designed to support the weight of the equipment, antennas, and any additional loads such as ice or wind. Calculating the loading capacity is essential to prevent overloading and compromising the tower's integrity. 3. Adhering to Design Codes and Standards: Compliance with relevant design codes and standards is crucial to ensure the safety and reliability of the steel communication tower. These codes and standards provide guidelines for structural design, material selection, fabrication, and installation practices. 4. Selecting the Right Material: Steel is the preferred material for communication towers due to its strength, durability, and cost-effectiveness. It is important to carefully select the type and grade of steel to meet the specific requirements of the tower design, taking into consideration factors such as corrosion resistance, yield strength, and weldability. 5. Designing the Foundation: The foundation of the tower is critical for maintaining stability and preventing settlement. The soil conditions at the tower site must be evaluated to determine the appropriate foundation design, whether it be a shallow concrete pad, drilled piers, or deep foundations. 6. Considering Access and Maintenance: The design should incorporate considerations for safe and convenient access to the tower for maintenance and repair activities. This may involve including ladders, platforms, and safety systems to ensure the technicians' safety when working at heights. 7. Addressing Aesthetics: Depending on the location and surrounding environment, aesthetics may play a significant role. The tower design should either blend in with the surroundings or be visually appealing, especially in urban areas or locations with strict zoning regulations. 8. Minimizing Environmental Impact: It is important to minimize the tower's environmental impact by considering factors such as wildlife protection, avoiding sensitive habitats, and utilizing eco-friendly construction practices. In conclusion, designing steel communication towers requires careful consideration of factors such as structural stability, loading capacity, compliance with codes and standards, appropriate material selection, foundation design, access and maintenance requirements, aesthetics, and environmental impact. By addressing these considerations, a well-designed steel communication tower can be constructed to provide reliable and efficient communication infrastructure.

- Q: What are the advantages of using steel structures in recreational facilities?

- There are several advantages of using steel structures in recreational facilities. Firstly, steel structures are known for their strength and durability. This makes them ideal for supporting large loads and withstanding various weather conditions, ensuring the safety and longevity of the recreational facility. Secondly, steel is a versatile material that can be easily fabricated and customized according to the specific design requirements of the facility. It allows for flexibility in creating unique and aesthetically pleasing structures, enhancing the overall visual appeal of the recreational facility. Additionally, steel structures are cost-effective in the long run. Due to their durability, they require minimal maintenance and repairs, reducing the overall operating costs. Moreover, steel is a recyclable material, making it an environmentally friendly choice. Lastly, steel structures offer fast construction times. The prefabrication of steel components allows for quick and efficient assembly on-site, resulting in shorter construction periods. This is beneficial for recreational facilities that need to be completed within a specific timeframe. Overall, the advantages of using steel structures in recreational facilities include strength, versatility, cost-effectiveness, and fast construction times, making it a preferred choice for developers and designers.

- Q: How are steel structures used in the construction of hospitality and tourism buildings?

- Steel structures are commonly used in the construction of hospitality and tourism buildings due to their strength, durability, and flexibility. Steel allows for large open spaces and long spans, making it ideal for constructing hotel lobbies, conference halls, and exhibition centers. Additionally, steel's fire-resistant properties provide a safer environment for guests, while its ability to withstand extreme weather conditions makes it suitable for building resorts in coastal areas. Moreover, steel structures can be easily customized and integrated with other materials, allowing architects to create unique and visually appealing designs that enhance the overall guest experience.

- Q: Can steel structures be designed to be resistant to electromagnetic pulses?

- Indeed, it is possible to design steel structures that can withstand electromagnetic pulses (EMPs). EMPs refer to intense bursts of electromagnetic radiation that can inflict significant harm on electronic devices and electrical systems. To safeguard against EMPs, specific precautions can be taken during the design and construction of steel structures. One viable approach involves the creation of a Faraday cage or a shielded enclosure using steel. A Faraday cage is an enclosure constructed from conductive materials, such as steel, which can obstruct or redirect electromagnetic fields. By enveloping sensitive equipment or critical infrastructure within a steel enclosure, the electromagnetic radiation from the EMP can be redirected away from the protected area, thus reducing its impact. Furthermore, grounding techniques can be employed to dissipate the energy of an EMP. Steel structures can be designed with appropriate grounding systems that channel the electromagnetic energy into the ground, minimizing its impact on the structure and its contents. Moreover, the selection of materials and components utilized in the construction of steel structures can also contribute to their resistance against EMPs. For instance, non-metallic materials should be minimized or avoided in critical areas, as they are more susceptible to damage from electromagnetic radiation. It is crucial to acknowledge that the level of resistance to EMPs hinges on the specific design and construction measures implemented. Hence, it is imperative to seek advice from experts in the field of electromagnetic shielding and protection to ensure the most effective design for the intended purpose of the steel structure.

- Q: How are steel structures designed to be resistant to electromagnetic interference?

- Steel structures can be designed to be resistant to electromagnetic interference (EMI) through several measures. Firstly, the use of steel as a primary construction material offers inherent shielding properties against electromagnetic waves. Steel has high electrical conductivity, which allows it to absorb and dissipate electromagnetic energy effectively. To enhance EMI resistance, additional strategies can be implemented during the design and construction phases. One common approach is to create a Faraday cage effect by enclosing sensitive equipment or areas within steel structures. A Faraday cage is an enclosure made of conductive material that blocks external electromagnetic fields from penetrating into the protected space. Furthermore, steel structures can be designed with proper grounding systems to direct and dissipate any electromagnetic energy that may be induced or conducted within the structure. This grounding system ensures that any potential interference is safely discharged to the earth, minimizing its impact on sensitive electronic devices. Careful consideration is also given to the layout and placement of electrical and communication cables within steel structures. These cables can be shielded or routed away from potential sources of electromagnetic interference to reduce the risk of signal degradation or disruption. In addition to these design measures, periodic testing and maintenance of the steel structure's electromagnetic shielding effectiveness can be conducted to ensure its continued resistance to EMI. This may involve using specialized equipment to measure the structure's electromagnetic shielding effectiveness and identifying any potential areas of improvement. Overall, by incorporating steel as a construction material, implementing appropriate shielding techniques, and maintaining proper grounding systems and cable routing, steel structures can be designed to resist electromagnetic interference and provide a safe and reliable environment for sensitive electronic equipment.

1. Manufacturer Overview

| Location | SHANDONG,China |

| Year Established | 2008 |

| Annual Output Value | Above US$20 Billion |

| Main Markets | WEST AFRICA,INDIA,JAPAN,AMERICA |

| Company Certifications | ISO9001:2008;ISO14001:2004 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | TIANJIN PORT/ QINGDAO PORT |

| Export Percentage | 0.6 |

| No.of Employees in Trade Department | 3400 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 150,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average, High |

Send your message to us

Heavy steel Workshop

- Loading Port:

- Tianjin Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 sqare meters m.t.

- Supply Capability:

- 50000 Square Meters/Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords