steel structure workshop warehouse building design, manufacture and installation

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Technical Parameters

Item Name | steel structure workshop warehouse building |

Main Material | Q235/Q345 Welded H Beam and Hot Rolled Section Steel |

Surface | Painted or Hot Dip Galvanized |

Roof & Wall Panel | EPS Sandwich panel /Single Corrugated Steel Sheet/ Colour sheet with Glass-wool, for customers choose |

Window | PVC Steel or Aluminum Alloy |

Door | Sliding Door or Rolling Up Door |

Service | Design, Fabrication and Installation |

We can make quotation according to customer's drawing or requirement; (size by length/width/height and wind speed), offering a free design drawing and all detailed drawings for installation. | |

Design software: Auto CAD,PKPM,MTS,3D3S, Tarch, Tekla Structures(Xsteel)V12.0.etc | |

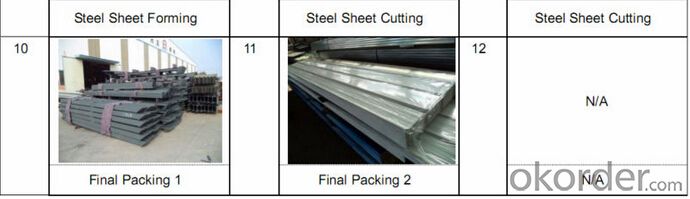

Packing | According to customer's requirement |

Load into 40/20GP,40HQ or 40OT |

- Q: What are the typical spans and heights achievable with steel structures?

- The typical spans and heights achievable with steel structures vary depending on the specific design and engineering requirements. However, steel structures are known for their high strength-to-weight ratio, allowing for longer spans and greater heights compared to other construction materials. In general, steel structures can achieve spans ranging from a few meters to over 100 meters, while heights can range from single-story buildings to skyscrapers reaching hundreds of meters. The versatility of steel as a construction material enables architects and engineers to create innovative and visually striking structures while maintaining structural integrity and safety.

- Q: How does steel compare to other materials in terms of fire resistance?

- Steel is known to have exceptional fire resistance properties, making it highly preferred over other materials in many applications. Unlike materials such as wood or plastic, steel does not burn or contribute to the spread of fire. It has a high melting point, ranging from 1370°C to 1530°C (2500°F to 2800°F), which means it can withstand intense heat for prolonged periods without losing its structural integrity. This characteristic allows steel structures to remain stable even in the event of a fire, providing valuable time for evacuation and firefighting efforts. Additionally, steel is not susceptible to thermal expansion or warping due to heat exposure, further enhancing its fire-resistant qualities. Moreover, steel can be coated with fire-resistant materials such as intumescent paints or concrete, further enhancing its fire resistance. Overall, steel's exceptional fire resistance properties, along with its strength and durability, make it a highly reliable material in terms of fire safety.

- Q: How are steel structures designed for efficient waste water treatment systems?

- Steel structures are designed for efficient waste water treatment systems by incorporating several key features. Firstly, steel is a highly durable and strong material, allowing for the construction of robust and long-lasting structures that can withstand the harsh conditions of waste water treatment facilities. Additionally, steel can be easily fabricated and customized to meet the specific needs of the system, enabling efficient design and construction processes. Moreover, steel structures can be prefabricated off-site, reducing on-site construction time and minimizing disruptions to the treatment process. Lastly, steel is a sustainable material that can be recycled, aligning with the eco-friendly goals of waste water treatment systems. Overall, steel structures provide an efficient and reliable solution for waste water treatment facilities.

- Q: How are steel structures designed for vibration control?

- Various techniques can be employed to control vibrations in steel structures. One approach commonly used is incorporating damping devices into the structure. These devices, such as tuned mass dampers or viscoelastic dampers, are strategically placed to absorb and dissipate the energy generated by vibrations, thereby reducing their amplitude. Another method involves optimizing the structural design to minimize resonance effects. By analyzing the natural frequencies of the structure and the expected vibration frequencies, engineers can adjust the dimensions and stiffness of the steel members to avoid resonance, which can amplify vibrations. Furthermore, vibration isolation systems can be utilized to mitigate vibrations. These systems typically involve installing rubber or elastomeric pads or bearings between the steel structure and its foundation. These materials act as shock absorbers, isolating the structure from ground vibrations and minimizing their transmission. Moreover, advanced modeling techniques, such as finite element analysis, are employed to simulate the behavior of the steel structure under different vibration scenarios. This enables engineers to identify areas of concern and make necessary modifications to enhance the structure's resistance to vibrations. In summary, controlling vibrations in steel structures involves using a combination of damping devices, optimization of the structural design, vibration isolation systems, and advanced modeling techniques. These measures ensure that the structure can withstand vibrations and minimize their effects, providing a safe and comfortable environment for occupants.

- Q: Can steel structures be designed to have long spans without intermediate supports?

- Yes, steel structures can be designed to have long spans without intermediate supports. Steel has excellent strength-to-weight ratio and can support large loads over long distances. Engineers use various design techniques, such as trusses, arches, and cantilevers, to create steel structures with long spans. Trusses are frameworks composed of interconnected steel members that can span large distances without intermediate supports. They distribute the load evenly across the structure, making it capable of supporting heavy loads. Arch structures utilize the inherent strength of curved shapes to create long-span steel structures. The curved shape allows the load to be transferred to the supports at the ends of the arch, enabling large spans without the need for intermediate supports. Additionally, cantilevers are another technique used in steel structure design to create long spans. Cantilevers are beams that are supported at only one end, allowing the structure to extend beyond the support point. By carefully designing the dimensions and the material properties of the cantilever, engineers can achieve long spans without intermediate supports. In summary, steel structures can indeed be designed to have long spans without the need for intermediate supports. Engineers utilize various design techniques, such as trusses, arches, and cantilevers, to create stable and robust steel structures capable of supporting large loads over long distances.

- Q: What is the role of steel in sustainable urban development?

- Steel plays a crucial role in sustainable urban development by providing structural strength, durability, and versatility for various construction applications. Its use in buildings and infrastructure allows for efficient use of materials, reduced energy consumption, and lower carbon emissions. Additionally, steel is highly recyclable, making it a sustainable choice that supports circular economy principles.

- Q: What is the role of steel in bridge construction?

- The role of steel in bridge construction is crucial as it offers exceptional strength and durability necessary to support the weight of the bridge, withstand heavy loads, and resist various environmental forces such as wind and earthquakes. Steel provides the structural framework for bridges, allowing for long spans and the flexibility to design different bridge types. Additionally, steel's high tensile strength enables the construction of lighter and more efficient bridge structures, while its versatility allows for customization and easy fabrication. Overall, steel is a fundamental material in bridge construction, ensuring safety, longevity, and efficient transportation infrastructure.

- Q: How to repair the steel structure workshop H steel column in the ground 1 meters high is hit by the car deformation, in the condition of not changing the column, how to restore and ensure structural load-bearing role?

- The steel plate is strengthened or the section steel is strengthened, and then the flame is adjusted by flame

- Q: Can steel structures be easily modified or expanded?

- Yes, steel structures can be easily modified or expanded due to their inherent strength, flexibility, and modularity. Steel components can be easily added, removed, or repositioned, allowing for modifications or expansions to be made efficiently and without compromising the structural integrity of the overall building. This adaptability makes steel structures a popular choice in construction projects that may require future modifications or expansions.

- Q: Steel structure platform cost

- Give me your drawings, the quota to be used, your construction organization plan and other relevant information to me. I'll calculate the cost for you

Send your message to us

steel structure workshop warehouse building design, manufacture and installation

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords