Prefabricated steel frame workshop warehouse building

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Prefabricated steel frame workshop warehouse building

Specification

1. Durable

2. Light Weight

3. Excelent quality

4. Atractive appearance

5.Easy and fast to install

6. Resistant 8-9 earthquake grade

7. Span life : over 50 years

8. Eco-friendly material: can be used for several times and can be recycled

| Name | Steel structure building | |

| Dimension | length | H beam 4000-15000 mm |

| thickness | web plate 6 -32 mm web plate 6 -40 mm | |

| height | 200 -1200 mm | |

| Color | avalible | |

| size | according to your requirement | |

| Advantages | 1. lower cost and beautiful outlook 2. high safty performance 3. easy to assemble and disassemble 4.installation with installation of experienced engineer 5. None -pollution | |

| Main componet | base | cement and steel foundation bolts |

| main frame | H beam | |

| material | Q 235 B , Q 345 B our main material | |

| purlin | C purlin or Z Purlin size from C 120 - 320 , Z 100 -20 | |

| bracing | X type or other type bracing made from angle and round pipe | |

| bolt | general bolt and high -strength bolts | |

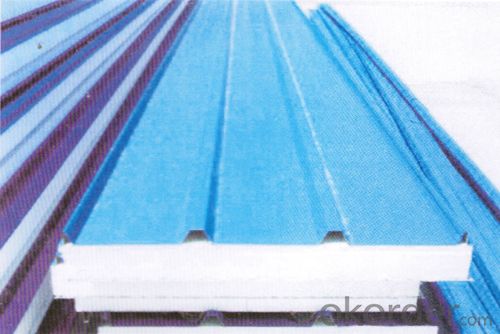

| roof & wall | sandwich panel and steel sheet | |

| door | sliding and rolling door | |

| window | plastic steel window | |

| surface | ||

| sheet | 0.35 -0.6 mm galvanized sheet | |

| accessories | semi - transparent skylight belts , ventilators , downpipe and galvanized gutter etc . | |

| Use | 1.workshop warehouse 2. steel web steel structure 3. steel H beam and H column 4. portal frame products 5. high rise project 6. other steel structure buildings | |

| Packing | main steel frame with 40 OT roof and panel load iin 40 HQ | |

| Drawing | Auto CAD , Sketchup , 3D ETC . | |

| Design parameter | If you would like to design for you , please offer us the following parameter : 1. length , width , height , eave height , roof pitch etc . 2. wind load , snow load , raining condition , aseismatic requirement etc . 3.demand for window and door 4.insulation material : sandwich panel ( thickness : 50 mm , 75mm , 100 mm etc ) and steel sheet . 5. crane : do you need the crane beam inside the steel structure and its capacity 6. other information if necessary | |

Fast construction metal shed sale with low cost

Why choose us

Specifications

fast building systems from china

1. high quality steel structure frame

2. low-price

3. easy to install

1. Why choose our building systems

1 More than 18 years’ experience

2 Light weight, high strength

3 Wide span: single span or multiple spans

4 Fast construction, easy installation and maintance

5 Low cost

6 Stable structure, earthquake proofing, water proofing, energy conserving and environmental protection

7 Long term service life: more than 50 years

2. Our building systems description

Our industral shed is an pre-engineered steel structure which is formed by the main steel framework linking up H section, Z section, and Csection steel components, roof and walls using a variety of panels. The steel workshop building is widely used for the large-scale workshop, warehouse, office building, steel shed, aircraft hangar etc.

- Q: What are the design considerations for steel commercial buildings?

- When designing steel commercial buildings, it is important to take into account various factors such as structural integrity, aesthetics, functionality, sustainability, and cost-effectiveness. Structural integrity is a crucial aspect to consider when designing steel commercial buildings. These structures must be able to withstand different types of loads, including wind, snow, and seismic forces. Steel structures are known for their strength and durability, making them an ideal choice for commercial buildings that require large open spaces and flexible layouts. Aesthetics also play a significant role in commercial buildings, as they often serve as a representation of the business or brand. Steel structures offer versatility in design, allowing for unique architectural features and creative façade options. The use of steel also allows for the incorporation of large windows and open spaces, creating an inviting and visually appealing environment. Functionality is another important consideration in commercial building design. The layout and design should optimize the functionality of the space and meet the specific needs of the business. Steel structures provide column-free spaces, offering flexibility for interior layouts and efficient utilization of floor space. This flexibility also allows for future expansions or modifications to the building. Sustainability is an increasingly important aspect in building design. Steel is a highly sustainable material, as it can be 100% recycled and reused without losing its properties. Moreover, steel structures can incorporate energy-efficient features, such as insulation, solar panels, and efficient HVAC systems, reducing the environmental impact of the building. Cost-effectiveness is a significant consideration for commercial buildings. Steel structures are usually quicker to construct compared to traditional building materials, resulting in reduced labor costs and minimal disruption to business operations. The durability and low maintenance requirements of steel buildings also contribute to long-term cost savings. In conclusion, the design considerations for steel commercial buildings encompass structural integrity, aesthetics, functionality, sustainability, and cost-effectiveness. By carefully taking these factors into account, architects and engineers can create efficient, visually appealing, and sustainable commercial buildings that meet the specific needs of businesses.

- Q: What are the design considerations for steel data centers?

- There are several important design considerations to keep in mind when designing steel data centers: 1. Structural Integrity: Steel is known for its strength and durability, making it an ideal material for data center construction. Designers must ensure that the steel framework is designed to withstand extreme weather conditions, seismic activity, and other potential hazards to maintain the structural integrity of the facility. 2. Thermal Management: Data centers generate a significant amount of heat due to the operation of servers and other equipment. Efficient thermal management is crucial to prevent overheating and ensure optimal performance. Steel data centers need to incorporate proper insulation, ventilation systems, and cooling mechanisms to maintain a stable and cool environment for the equipment. 3. Power Distribution: Data centers require a reliable and efficient power distribution system to ensure uninterrupted operation. Designers must consider the load capacity, redundancy, and backup power options, such as generators or uninterruptible power supply (UPS) systems. Steel data centers often require dedicated spaces for housing electrical equipment and cabling. 4. Scalability and Flexibility: Data centers need to be designed with scalability in mind to accommodate future growth and technological advancements. Steel structures allow for easy expansion and modifications, making it easier to accommodate additional equipment or reconfigure the layout as needed. 5. Security: Data centers store sensitive information and need to be highly secure. Design considerations include access control systems, surveillance cameras, fire suppression systems, and physical barriers to prevent unauthorized access and protect against potential threats. 6. Connectivity: Data centers rely on robust connectivity to ensure fast and reliable data transmission. Designers need to consider the routing and placement of network cables and fiber optic infrastructure to optimize connectivity within the facility. 7. Environmental Impact: Sustainable design practices should be considered when building steel data centers. Incorporating energy-efficient systems, green building materials, and renewable energy sources can help reduce the environmental impact and improve the facility's overall efficiency. 8. Maintenance and Accessibility: Designers must consider ease of maintenance and accessibility for equipment installation, repairs, and upgrades. Ample space, clear pathways, and proper cable management systems should be incorporated into the design to facilitate maintenance and ensure optimal performance. In summary, the design considerations for steel data centers revolve around structural integrity, thermal management, power distribution, scalability, security, connectivity, environmental impact, and accessibility. By addressing these considerations, designers can create high-performance and efficient data centers that meet the demands of modern technology.

- Q: What are the design considerations for steel mezzanine platforms?

- Some design considerations for steel mezzanine platforms include load capacity, structural stability, access points, safety features, and integration with existing infrastructure. The platform should be designed to support the anticipated load, ensuring that it can safely accommodate the intended use. Structural stability is crucial to prevent any collapse or deflection, requiring careful analysis and design of the support structure. Access points such as stairs, ladders, or ramps should be included to provide safe and convenient entry and exit. Safety features like guardrails, handrails, and non-slip surfaces should be incorporated to minimize the risk of accidents. Lastly, the design should take into account the integration with the existing infrastructure, considering factors like clearance height, utility connections, and fire safety requirements.

- Q: How do steel structures handle heavy loads?

- Steel structures are able to handle heavy loads due to the inherent strength and durability of steel as a construction material. Steel has a high strength-to-weight ratio, meaning it can support large amounts of weight while remaining relatively lightweight itself. Additionally, steel's flexibility allows it to distribute and absorb heavy loads effectively, preventing structural failure. Steel structures also benefit from their ability to be designed and fabricated to precise specifications, ensuring that they can withstand the anticipated loads and stresses placed on them.

- Q: How does a steel structure differ from other types of structures?

- A steel structure differs from other types of structures primarily in its material composition and construction method. Unlike wood, concrete, or brick structures, steel structures are made primarily from steel components, providing them with superior strength, durability, and flexibility. Steel structures can be easily fabricated off-site and assembled on-site, allowing for faster construction times. Additionally, steel structures offer better resistance to fire, earthquakes, and extreme weather conditions.

- Q: How are steel structures designed to provide adequate fire protection?

- The provision of adequate fire protection in steel structures is achieved through various measures. Firstly, fire-resistant coatings, such as intumescent paints or cementitious sprays, are often applied to the steel used in construction. These coatings expand when exposed to high temperatures, creating an insulating char layer that helps slow down heat transfer to the steel structure. In addition to fire-resistant coatings, fireproof insulation materials like mineral wool or vermiculite boards can also be incorporated into steel structures. These materials are placed between the steel members to enhance fire resistance and prevent the spread of fire. Furthermore, fire-resistant barriers and compartmentalization are commonly included in the design of steel structures. Fire-resistant barriers, such as firewalls or fire-resistant doors, are strategically positioned to divide the building into sections, thereby limiting the spread of fire and safeguarding occupants and property. Compartmentalization involves creating fire-resistant compartments within the structure, which can effectively impede the rapid spread of fire and provide safe evacuation routes. Moreover, the fire protection of a structure can be influenced by the selection and arrangement of steel members. Steel members with larger cross-sections or those embedded within concrete offer better fire resistance compared to thinner sections. The arrangement of steel members can also take into account fire-safety factors, such as avoiding long uninterrupted spans or providing additional fire protection to critical areas. Lastly, the inclusion of fire detection and suppression systems is crucial in steel structures to ensure early fire detection and effective fire suppression. These systems consist of smoke detectors, fire alarms, sprinkler systems, and fire extinguishers, strategically placed to minimize response time and contain the fire before it can cause extensive damage. In conclusion, steel structures are designed to provide adequate fire protection by employing fire-resistant coatings, insulation materials, barriers, compartmentalization, thoughtful member selection, and fire suppression systems. These measures collectively minimize the risk to occupants and property.

- Q: What are the considerations for designing steel structures in areas with high humidity?

- Careful consideration is necessary when designing steel structures in areas with high humidity to prevent corrosion and ensure the longevity and safety of the structure. Some key factors to consider include: 1. Selection of materials: It is crucial to choose the right type of steel and protective coatings. Often, stainless steel or weathering steel, which form a protective oxide layer, are preferred. Another effective option is to galvanize the steel or apply corrosion-resistant coatings. 2. Ventilation and drainage: Incorporating proper ventilation and drainage systems is important to prevent moisture accumulation. This involves designing for natural airflow and providing sufficient drainage to minimize steel exposure to standing water or excessive moisture. 3. Control of condensation: Condensation can occur when warm, moist air comes into contact with colder surfaces. To minimize condensation on steel surfaces, it is important to use proper insulation and vapor barriers. Additionally, designing for thermal breaks and providing adequate insulation can help reduce temperature differences and mitigate potential condensation issues. 4. Maintenance and inspection: Regular maintenance and inspections are essential to identify and address any signs of corrosion or damage. It is necessary to periodically clean, paint, and reapply protective coatings to maintain the integrity of the steel structure. 5. Humidity control: Controlling humidity levels within the structure may be necessary in some cases. This can be achieved by using dehumidifiers or proper HVAC systems to maintain relative humidity levels within an acceptable range. 6. Consideration of environmental factors: High humidity areas often come with other environmental factors such as saltwater exposure, coastal environments, or chemical pollutants. Designers should consider these factors to select appropriate materials and protective measures specific to the local conditions. 7. Structural design: The structural design should take into account the potential effects of high humidity, such as increased corrosion rates and reduced load-bearing capacity over time. It is important to follow appropriate safety factors and design codes to ensure the structural integrity of the steel elements. By considering these factors, designers can minimize the risk of corrosion and ensure the durability and safety of steel structures in areas with high humidity.

- Q: How are steel structures designed for industrial applications?

- The systematic and rigorous design process of steel structures for industrial applications guarantees that they meet the specific demands and requirements of industrial settings. To achieve this, several key steps are taken, including conceptualization, analysis, detailing, and fabrication. To start with, the purpose, function, and load requirements of the steel structure are thoroughly understood during the conceptualization phase. This entails considering factors like the industry type, layout and dimensions of the industrial facility, equipment to be used, and the expected loads and stresses that the structure will face. Once the conceptualization phase is finished, structural engineers analyze the loads and forces acting on the structure. This includes both static and dynamic loads, such as dead loads, live loads, wind loads, seismic loads, and other relevant factors. By employing advanced computer modeling and calculations, engineers determine the optimal design to resist these loads while ensuring structural stability and safety. Following the analysis, the detailing phase commences, where the structural elements are designed and specified. This involves selecting suitable steel sections, connections, and fasteners to ensure the structure can withstand the expected loads. Factors like steel grade, thickness, cross-sections, connection details, and welding requirements are taken into account. The design must also comply with industry standards and codes, such as AISC codes. Once the design is finalized, it is translated into detailed fabrication drawings and specifications. These drawings provide all the necessary information for the fabrication and assembly of the steel structure, including dimensions, material specifications, welding details, and connection requirements. The drawings act as a blueprint for the fabrication process, ensuring accuracy and consistency in the construction phase. During fabrication, skilled workers, such as welders and steel fabricators, follow the detailed drawings and specifications to construct the steel structure. Quality control measures are implemented to guarantee that the fabrication aligns with the design requirements and industry standards. In conclusion, the design process of steel structures for industrial applications is meticulous and comprehensive. It involves conceptualization, analysis, detailing, and fabrication to ensure that the structure can withstand the industrial environment's loads and forces while maintaining integrity, safety, and efficiency.

- Q: How are steel structures used in the construction of parking garages?

- Steel structures are commonly used in the construction of parking garages due to their strength, durability, and flexibility. Steel beams and columns provide the necessary support for multi-level structures, allowing for larger spans and open spaces. Additionally, steel's lightweight nature allows for efficient construction and reduces the load on the foundation. The use of steel also enables the incorporation of architectural features, such as cantilevers and unique shapes, ensuring a visually appealing parking structure.

- Q: How are steel structures designed to accommodate plumbing and HVAC systems?

- Steel structures are designed with specific consideration given to the placement and support of plumbing and HVAC systems. This is achieved through careful coordination between the structural engineer and the mechanical engineer, who work together to ensure that the steel framework can accommodate the necessary pipes, ducts, and equipment. Openings, such as holes or notches, are strategically incorporated into the steel beams or columns to allow for the passage of these systems while maintaining the structural integrity of the building. Additionally, load-bearing capacity and stability of the steel structure are taken into account to ensure the plumbing and HVAC systems can be properly supported without compromising the overall strength and safety of the building.

Send your message to us

Prefabricated steel frame workshop warehouse building

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords