Prefabricated steel structure warehouse

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Prefabricated steel structure warehouse materials:

| Material | Specification |

| Length | Single slope, double slope, muti slope |

| Width | Single span, double-span, Multi-span |

| Height | single floor, double floors |

| Column | Q235, Q345 welded H section steel |

| Beam | Q235, Q345 welded H section steel |

| Purlin | Q235 C channel or Z channel |

| Knee brace | Q235 angle steel |

| Vertical and transversal support | Q235 angle steel, round bar or steel pipe |

| Tie bar | Q235 steel pipe |

| Brace | Q235 round bar |

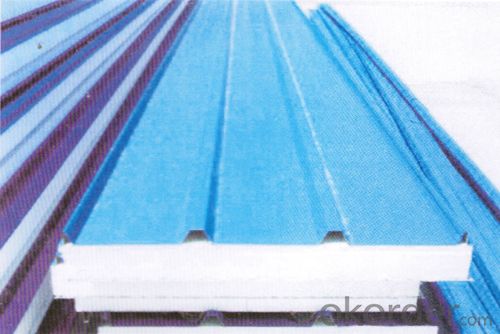

| Cladding system | EPS, PU, Fiber glass wool sandwich panels or corrugated steel sheet with fiber glass wool insulation. available in Diferent colors&gauge |

| Partition wall | sandwich panels (EPS, PU, Fiber glass wool etc.) available in Diferent colors&gauges |

| Door | sandwich panel sliding door or roller door |

| Gutter | stainless steel or color steel sheet |

| Rainspout: | PVC |

| Live load on roof | In 120kg/Sqm (Color steel panel surrounded) |

| Wind resistance grade | 12 grades |

| Earthquake-resistance | 8 - 9 grades |

| Structure usage | Up to 50 years |

| Finishing options | vast array of colors and textures available |

| Paint Options | Gray paint, red paint, white paint, expoxy zinc etc. Or Galvanized |

- Q: How are steel structures designed for differential settlement?

- Steel structures are designed for differential settlement by incorporating flexible connections and joints that can accommodate the uneven settlement of the foundation. Additionally, the structural members are designed with sufficient strength and stiffness to minimize the effects of differential settlement and maintain overall stability.

- Q: What are the common design considerations for steel canopies?

- When designing steel canopies, there are several common considerations that must be taken into account to ensure a successful and functional structure. 1. Structural Integrity: The first and foremost consideration is the structural integrity of the canopy. The design should be able to withstand various loads such as wind, rain, snow, and seismic forces. Structural calculations and analysis should be performed to determine the appropriate size and strength of the steel members to ensure stability and safety. 2. Aesthetics: Steel canopies often serve as architectural elements and should therefore be visually appealing. Design considerations such as the overall shape, color, and finishes should be taken into account to create an attractive and harmonious structure that complements the surrounding environment. 3. Functionality: The canopy should fulfill its intended purpose effectively. This could include providing shade, protection from rain or snow, or acting as a shelter for specific activities. The design should incorporate features such as appropriate slope, drainage systems, and effective ventilation to ensure functionality. 4. Accessibility: Considerations should be made to ensure that the canopy is accessible to all users, including those with disabilities. This may involve incorporating ramps, handrails, and other accessibility features to comply with building codes and regulations. 5. Materials and Durability: The choice of steel and other materials used in the canopy's construction should be carefully considered to ensure durability and longevity. Factors such as corrosion resistance, weathering properties, and maintenance requirements should be taken into account to ensure the canopy can withstand the elements and retain its structural integrity over time. 6. Lighting and Electrical Systems: If lighting is required, the design should incorporate appropriate fixtures and wiring systems to ensure adequate illumination. Electrical considerations such as power supply, outlets, and grounding should also be addressed during the design phase. 7. Environmental Impact: Designers should aim to minimize the environmental impact of steel canopies by considering sustainable design practices. This could include incorporating renewable energy sources, such as solar panels, or using recycled materials during construction. Overall, the design of steel canopies should consider structural integrity, aesthetics, functionality, accessibility, materials and durability, lighting and electrical systems, and environmental impact. By addressing these common considerations, designers can create steel canopies that are not only visually appealing but also safe, functional, and environmentally conscious.

- Q: What are the considerations for designing steel roof trusses?

- When designing steel roof trusses, several important considerations need to be taken into account. These considerations include the span and load requirements, the overall architectural design, the environmental conditions, the material selection, and the construction process. Firstly, the span and load requirements are crucial in determining the size and configuration of the steel roof trusses. The span refers to the distance between supports, and the load requirements depend on factors such as the type of roof material, snow load, wind load, and any potential live loads. These factors determine the size and spacing of the trusses to ensure they can safely support the intended loads. Secondly, the overall architectural design of the building plays a significant role in the design of the steel roof trusses. The trusses need to be designed to complement and support the desired architectural style, whether it is a traditional or modern design. The shape, pitch, and height of the roof, as well as any desired design elements such as skylights or dormers, need to be taken into consideration during the design process. Environmental conditions are another crucial consideration. Steel roof trusses must be designed to withstand the specific climatic conditions of the location, including high winds, heavy snowfall, seismic activity, or extreme temperatures. The trusses should be able to withstand these conditions and provide a safe and durable roof structure. Material selection is also important when designing steel roof trusses. The choice of steel and its grade can impact the durability, strength, and cost of the trusses. The designer must consider factors such as corrosion resistance, fire resistance, and the potential for expansion and contraction due to temperature changes. Lastly, the construction process should be considered during the design phase. The trusses need to be designed for ease of fabrication, transportation, and erection on-site. They should be designed in a way that minimizes waste and simplifies the construction process, ensuring cost-effectiveness and efficiency. In conclusion, designing steel roof trusses requires careful consideration of factors such as span and load requirements, architectural design, environmental conditions, material selection, and construction process. By taking these considerations into account, a well-designed steel roof truss system can be created that provides structural integrity, durability, and aesthetic appeal.

- Q: What are the considerations for steel structure design in earthquake-prone areas?

- When designing steel structures in earthquake-prone areas, it is important to take into account several key considerations to ensure the safety and stability of the structure during seismic events. The first consideration is to adhere to the specific seismic design codes and regulations for the region. These codes provide guidelines for designing, constructing, and maintaining structures in earthquake-prone areas. A thorough structural analysis must be performed to determine the expected seismic forces and their effects on the steel structure. This analysis involves assessing the building's response to ground motion, evaluating the strength and deformation capacity of the steel elements, and considering the interaction between various components. Steel structures in earthquake-prone areas should be designed with high ductility and redundancy. This means that the structure should be able to deform without losing its load-carrying capacity, and it should be able to redistribute loads and resist failure even if certain elements are damaged. Moment-resisting frames are commonly used in seismic design to provide resistance against lateral forces. These frames consist of beams and columns connected by rigid or semi-rigid connections, allowing them to effectively transfer forces and moments. Base isolation techniques can be used to separate the structure from the ground using flexible bearings or isolators. This helps to reduce the transmission of seismic energy to the building. Damping devices such as viscoelastic dampers or tuned mass dampers can also be incorporated to dissipate energy during earthquakes. Existing steel structures in earthquake-prone areas may need to be strengthened to meet the seismic design requirements. Techniques such as adding bracing systems, steel jackets, or external post-tensioning can be employed to improve the structure's resistance to earthquakes. Considering the interaction between the steel structure and the underlying soil is crucial. The characteristics of the soil, such as its stiffness and damping properties, can significantly affect the seismic response of the structure. Soil-structure interaction analysis should be conducted to ensure the design accounts for these effects. Regular quality control checks and inspections during construction are essential to ensure that the steel structure is being built according to the design specifications. Special attention should be given to welding, connections, and material quality to ensure the integrity of the structure. By considering these aspects, engineers can design steel structures that can withstand seismic forces and minimize damage, ensuring the safety of occupants and preserving the structural integrity of the building in earthquake-prone areas.

- Q: What are the sustainability benefits of using steel structures?

- There are several sustainability benefits of using steel structures. Firstly, steel is a highly recyclable material, which means that it can be reused and repurposed, reducing the need for new raw materials and minimizing waste. Additionally, steel structures have a longer lifespan compared to other construction materials, reducing the need for frequent replacements and thereby conserving resources. Steel is also known for its strength and durability, which allows for lighter and more efficient designs, resulting in reduced energy consumption during construction and operation. Lastly, steel structures are resistant to pests, fire, and natural disasters, providing a safer and more resilient built environment.

- Q: How do steel structures provide resistance against fire-induced collapse?

- Steel structures provide resistance against fire-induced collapse through several mechanisms. Firstly, steel has a high melting point, typically around 1370°C (2500°F), which means it can withstand higher temperatures compared to other materials like wood or concrete. This allows steel structures to maintain their structural integrity for a longer duration during a fire. Secondly, steel has a low thermal conductivity, meaning it does not readily transfer heat. This characteristic slows down the transfer of heat from the fire to the steel structure, preventing rapid temperature rise and maintaining its strength. Additionally, steel members in a structure are often protected by fire-resistant materials like intumescent coatings or fireproof insulation. These coatings or insulation act as a barrier, delaying the heating of the steel and providing extra time for evacuation or firefighting efforts. Furthermore, steel structures are designed using fire-resistant techniques such as compartmentation, fire-resistant walls, and fire barriers. These measures help contain the fire, preventing its spread and reducing the overall impact on the structure. Overall, the combination of steel's high melting point, low thermal conductivity, fire-resistant coatings, and design techniques make steel structures more resistant to fire-induced collapse compared to other materials.

- Q: What are the different types of steel foundations?

- There are several types of steel foundations commonly used in construction, including drilled pier foundations, helical pile foundations, and steel H-pile foundations.

- Q: What are the different types of steel roof systems used in building structures?

- Building structures commonly utilize various types of steel roof systems. Some of the most popular options include the following: 1. Standing seam roofs display vertical panels that interlock with each other. These roofs have raised seams that create a sleek and modern appearance. They are renowned for their durability, ability to withstand harsh weather conditions, and minimal maintenance needs. 2. Corrugated metal roofs consist of sheets with repetitive ridges and valleys, resulting in a wavy pattern. They are lightweight, easy to install, and offer excellent protection against severe weather. These roofs are often found in industrial and agricultural buildings. 3. Ribbed metal roofs feature horizontal raised ridges across the sheets, which enhance the roof's structural integrity, making it more resistant to impacts and increasing its load-bearing capacity. They are commonly used in commercial and residential buildings. 4. Architectural metal roofs provide a wide range of design and appearance options. They can imitate the look of other materials, such as wood or tile, while maintaining the strength and durability of steel. These roofs are popular in upscale residential and commercial projects. 5. Metal shingle roofs consist of individual pieces that are installed similarly to traditional asphalt shingles. They come in various shapes and sizes, allowing for diverse aesthetic choices. Metal shingle roofs offer the longevity and resistance to fire and pests associated with steel, while providing a more traditional appearance. It's important to consider specific building requirements, such as size, architectural style, climate, and budget, when selecting a steel roof system. Seeking guidance from a professional contractor or architect can be beneficial in determining the most suitable option for a particular structure.

- Q: How do steel structures perform in terms of vibration control?

- Steel structures generally perform well in terms of vibration control. Steel is a strong and rigid material, which allows it to resist and dampen vibrations effectively. Moreover, steel structures can be designed and reinforced to further enhance their vibration control capabilities. Overall, steel structures are commonly used in applications where vibration control is crucial, such as bridges, high-rise buildings, and industrial facilities.

- Q: What are the common design considerations for steel structures in museums and cultural buildings?

- Some common design considerations for steel structures in museums and cultural buildings include: 1. Structural Integrity: Steel is chosen for its strength and durability, ensuring the safety and stability of the buildings. The design should consider the load-bearing capacity of the steel structure to accommodate the weight of exhibits, equipment, and visitors. 2. Flexibility and Adaptability: Steel allows for flexibility in design, enabling architects to create large open spaces and accommodate future changes or expansions in the building layout. This is particularly important for museums and cultural buildings where exhibit layouts may change over time. 3. Aesthetics: The visual appeal of a museum or cultural building is crucial to its overall design. Steel structures offer various architectural possibilities, allowing for unique and visually striking designs that enhance the cultural significance of the building. 4. Environmental Considerations: Sustainable design is a major consideration in modern construction. Steel is a highly recyclable material, and its use in museum and cultural building structures can contribute to achieving sustainability goals. 5. Acoustic and Thermal Performance: Museums and cultural buildings often require controlled environments to protect sensitive exhibits. Steel structures can provide excellent acoustic and thermal insulation, helping to maintain stable temperature and humidity levels within the building. 6. Fire Resistance: Fire safety is a critical factor in the design of any building, especially those housing valuable artifacts or historic items. Steel structures can be designed to meet fire resistance standards, ensuring the safety and preservation of the cultural assets. 7. Construction Speed and Efficiency: Steel structures are typically prefabricated off-site, allowing for faster construction times. This can be advantageous when there are tight deadlines or budget constraints for museum or cultural building projects. Overall, the design considerations for steel structures in museums and cultural buildings revolve around structural integrity, flexibility, aesthetics, sustainability, environmental performance, fire safety, and efficient construction methods.

Send your message to us

Prefabricated steel structure warehouse

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords