All Categories

- - Steel Wire Rod

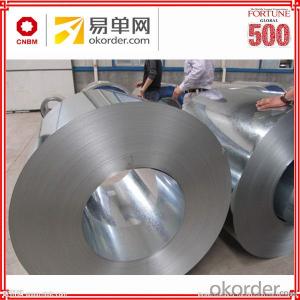

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How does the choice of cold-rolled steel impact the efficiency and performance of HVAC systems?

The choice of cold-rolled steel can significantly impact the efficiency and performance of HVAC systems. Cold-rolled steel offers several advantages such as increased strength, improved dimensional accuracy, and a smoother surface finish. These properties allow for better airflow and reduced friction within the HVAC system, resulting in improved energy efficiency. Additionally, cold-rolled steel is less prone to corrosion and deformation, ensuring longer lifespan and better performance of the system. Therefore, selecting cold-rolled steel for HVAC components can enhance overall system efficiency, performance, and durability.

How does cold-rolling differ from hot-rolling in steel production?

Cold-rolling and hot-rolling are two different methods used in steel production. Cold-rolling involves the process of rolling steel at room temperature, while hot-rolling involves rolling steel at a high temperature. The main difference between the two is that cold-rolling results in a smoother and more precise finish, while hot-rolling produces a rougher and less precise surface. Additionally, cold-rolling increases the strength and hardness of the steel, making it more suitable for applications requiring high strength and dimensional accuracy. In contrast, hot-rolling allows for easier shaping and forming of the steel due to its higher malleability.

How is cold-rolled steel manufactured?

Cold-rolled steel is manufactured through a process called cold rolling, where hot-rolled steel is further processed by passing it through rollers at room temperature. This process helps to improve the steel's surface finish, dimensional accuracy, and mechanical properties by compressing and flattening the material. Additionally, cold-rolling can also reduce the thickness of the steel sheet, making it more suitable for various applications such as automotive bodies, appliances, and construction materials.

How does cold-rolled steel impact the quality of printed materials in the printing industry?

Cold-rolled steel does not directly impact the quality of printed materials in the printing industry. Cold-rolled steel is primarily used in the manufacturing of printing presses and other machinery, which indirectly affects the printing process. The quality of printed materials is influenced by various factors such as the type of paper, ink quality, printing technique, and operator skills, rather than the steel used in the machinery.

Wholesale Cold Rolled Steel from supplier in Nepal

Our team is highly experienced in the field and can assist you in selecting the right Cold Rolled Steel products for your specific requirements. We offer competitive prices and prompt delivery to ensure your projects stay on schedule. Additionally, our technical support team is available to provide guidance and assistance throughout the process, ensuring the successful completion of your projects.

Our Cold Rolled Steel products are of the highest quality, manufactured using advanced technology and strict quality control measures. They are suitable for various applications, including construction, automotive, and manufacturing industries. We offer a wide range of thicknesses and widths to meet your specific needs.

At CNBM, we are committed to providing excellent customer service and building long-term partnerships with our clients. We understand the unique challenges and requirements of the Nepalese market and are dedicated to meeting and exceeding your expectations.

Contact us today to discuss your Cold Rolled Steel needs in Nepal and let us provide you with the best solutions and support for your projects.

Our Cold Rolled Steel products are of the highest quality, manufactured using advanced technology and strict quality control measures. They are suitable for various applications, including construction, automotive, and manufacturing industries. We offer a wide range of thicknesses and widths to meet your specific needs.

At CNBM, we are committed to providing excellent customer service and building long-term partnerships with our clients. We understand the unique challenges and requirements of the Nepalese market and are dedicated to meeting and exceeding your expectations.

Contact us today to discuss your Cold Rolled Steel needs in Nepal and let us provide you with the best solutions and support for your projects.