All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

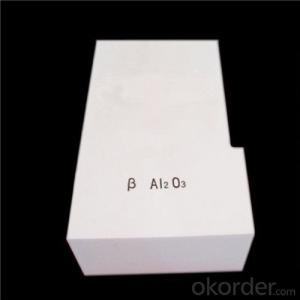

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Q & A

What are the different curing methods for refractory bricks?

There are several curing methods for refractory bricks, including air curing, steam curing, and heat curing. Air curing involves allowing the bricks to dry naturally in the air, which can take several weeks. Steam curing involves exposing the bricks to steam under pressure, which accelerates the drying process and reduces curing time. Heat curing, on the other hand, involves gradually increasing the temperature of the bricks in a controlled environment, allowing them to dry and harden over time. Each method has its advantages and is chosen based on the specific requirements and conditions of the refractory materials being used.

How do refractory bricks perform in regenerators?

Refractory bricks perform exceptionally well in regenerators due to their ability to withstand high temperatures, thermal shocks, and chemical reactions. They provide excellent insulation and heat retention properties, allowing for efficient heat transfer and regeneration of the furnace. Additionally, refractory bricks have high mechanical strength and resistance to abrasion, ensuring long-lasting performance in regenerators.

What are the different refractory materials used in bricks?

Some of the common refractory materials used in bricks include fireclay, silica, alumina, magnesia, and zirconia. These materials have high melting points and can withstand extreme temperatures, making them ideal for applications in furnaces, kilns, and other high-temperature environments.

Wholesale Refractory Bricks from supplier in Nepal

We are a Refractory Bricks supplier serving the Nepal, mainly engaged in the sale, quotation, and technical support services of various Refractory Bricks products in the Nepal region. We are a subsidiary platform of the Fortune Global 500 company CNBM, able to provide you with one-stop Refractory Bricks procurement services in the Nepal. Not only do we have a wide range of Refractory Bricks products, but after years of market development in the Nepal, we can also provide valuable experience for your projects.

Hot Search

- Monolithic Refractories in Afghanistan

- Ceramic Fiber Products in Lesotho

- Refractory Bricks in Bahrain

- Raw Materials For Refractory in Ecuador

- Ceramic Fiber Products in Chad

- Refractory Bricks in Denmark

- Refractory Bricks in Uzbekistan

- Monolithic Refractories in Thailand

- Monolithic Refractories in Ireland

- Ceramic Fiber Products in Nigeria