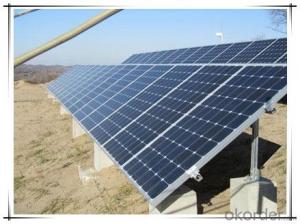

Best Quality Solar Bracket

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 3000 watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

Solar panel bracket is designed for large commercial solar plant. It is suitable for frame or frameless solar modules. Because of the concise design, the material of this panel bracket is very economical. So it is very competitive in this market.

Specification

1.Material:prefab C,U section steel,steel tubes

2.Surface:Hot dip galvanized

3.Size:as clients's requiremens

4.Price: reasonable price

Description

| Material | Galvanized fabricated low carbon steel |

| Zinc coating | 270-600g/ m² |

| Design snow Load | 1.5KN/m² |

| Design wind Load | 55m/s or 200km/h |

| Angle of elevation | 0°-45° |

| Production Standard | TUV, GB/5237-2008 |

| Design Standard | AS/NZS 170 |

Solar Panel Bracket Advantage

1)The Solar Panel Bracket is suitable for flat roofs of various structures or for the ground.

2)One end of the cross-beam is connected firmly with the ground structure by base bracket and hex-bolts and the another end is connected to the support leg forming a stable and strong tripod structure.

3)The connecting foot is made up of stainless steel to enhance the load bearing capacity.

- Q: What are the different types of steel cladding systems used in building structures?

- Building structures commonly utilize various types of steel cladding systems, which serve the purpose of providing both protection and aesthetic appeal. These systems are designed to withstand environmental factors while maintaining durability. The following are some of the frequently employed steel cladding systems: 1. Standing Seam Cladding: This system involves the use of interlocking metal panels joined together by raised seams. The seams not only enhance the appearance but also offer resistance against water infiltration and wind uplift. 2. Corrugated Steel Cladding: Industrial and agricultural buildings often use corrugated steel panels. These panels possess parallel ridges and grooves that not only add strength but also create a visually distinctive effect. Corrugated steel cladding is renowned for its ability to endure harsh weather conditions. 3. Insulated Metal Panels (IMPs): IMPs are composite panels comprising a rigid foam insulation core sandwiched between two metal skins. This cladding system exhibits superior thermal insulation, strength, and durability. It is commonly found in commercial and industrial buildings. 4. Metal Composite Panels (MCPs): MCPs consist of two metal sheets bonded to a core material such as polyethylene or mineral-filled fire-retardant material. These panels provide a sleek and contemporary appearance, as well as effective thermal and acoustic insulation properties. They are often utilized in high-rise buildings and architectural facades. 5. Perforated Metal Cladding: Perforated metal panels are employed to create visually appealing facades while allowing natural light and airflow. These panels feature patterns of small holes or openings that can be customized to achieve desired levels of transparency and aesthetic effects. These examples represent only a fraction of the steel cladding systems utilized in building structures. Each type offers unique advantages and is suitable for different applications, depending on factors such as the building's design, function, and location. Careful consideration and consultation with professionals are crucial when selecting the appropriate steel cladding system for a specific building project.

- Q: What are the design considerations for steel staircases?

- Some key design considerations for steel staircases include structural stability, load-bearing capacity, proper dimensions and proportions, safety features such as handrails and non-slip surfaces, aesthetics, ease of maintenance and durability, and compliance with building codes and regulations.

- Q: How are steel structures used in bridges?

- Steel structures are commonly used in bridges due to their strength, durability, and versatility. Steel provides the necessary support and stability required to span large distances and carry heavy loads. In bridge construction, steel is used for various components such as beams, girders, trusses, and cables. One of the key advantages of steel structures in bridges is their high tensile strength. Steel has a much higher tensile strength compared to other construction materials like concrete or wood. This allows for longer and wider spans between bridge supports, reducing the need for additional piers or pillars. Steel structures can also withstand extreme weather conditions, such as strong winds or earthquakes, making them ideal for bridges in areas prone to such events. Steel is also highly durable and requires minimal maintenance compared to other materials. It is resistant to corrosion and decay, making it suitable for long-lasting bridge structures. Additionally, steel structures can be prefabricated off-site, which helps to reduce construction time and costs. The versatility of steel allows for innovative bridge designs and the use of different types of bridges. Steel can be shaped and molded into various forms, enabling the construction of arch bridges, suspension bridges, cable-stayed bridges, and truss bridges. Each type of bridge has its advantages and is suited for different spans and load requirements. Moreover, steel structures in bridges can be easily repaired or modified if necessary. If a bridge needs to be expanded or reinforced, steel components can be added or replaced without major disruptions to traffic flow. In conclusion, steel structures are extensively used in bridges due to their strength, durability, versatility, and cost-effectiveness. They enable the construction of long-lasting bridges that can span large distances and carry heavy loads. Steel bridges are resilient, require minimal maintenance, and can be designed in various forms to suit specific needs.

- Q: How are steel structures designed to be resistant to pests and termites?

- Steel structures are inherently resistant to pests and termites due to the material's characteristics. Unlike wood, which pests can easily penetrate and feed on, steel does not provide a food source for insects. Additionally, the smooth and hard surface of steel makes it difficult for pests to burrow or make their way into the structure. Moreover, steel structures can be sealed tightly, eliminating any gaps or entry points for pests. Overall, the use of steel in construction greatly minimizes the risk of pest infestation and termite damage.

- Q: What are the different types of steel trusses used in construction?

- There are several types of steel trusses commonly used in construction, including the Pratt truss, Warren truss, Howe truss, and King post truss. These trusses vary in their design and arrangement of steel members, allowing for different load-bearing capacities and structural stability. The choice of truss type depends on the specific requirements of the construction project and the desired aesthetic or architectural design.

- Q: How are steel structures designed for long spans and open spaces?

- Steel structures are designed for long spans and open spaces by utilizing the inherent strength and flexibility of steel as a construction material. The design process involves careful consideration of factors such as load distribution, structural stability, and deflection control. By using innovative techniques such as truss systems, arches, and cantilevers, steel structures can efficiently span large distances while maintaining structural integrity and maximizing open space.

- Q: What are the guidelines for the fabrication and welding of steel structural members?

- Ensuring the integrity, safety, and performance of a structure requires adherence to essential guidelines for the fabrication and welding of steel structural members. Several key aspects must be considered during the process: 1. Material Selection: The first step involves selecting the appropriate steel material that meets required specifications such as strength, ductility, and corrosion resistance as specified by relevant codes and standards. 2. Design and Engineering: Strict adherence to the provided structural engineer's design is crucial. This includes details such as dimensions, tolerances, connections, and welding requirements to maintain structural integrity. 3. Cutting and Shaping: Achieving desired dimensions and shapes requires cutting and shaping steel members. Following guidelines for cutting methods, such as shearing, sawing, or flame cutting, ensures accurate and clean cuts. Additionally, proper tools and techniques should be used to shape the steel members according to design requirements. 4. Welding Procedures: Welding is a critical process in steel structural fabrication. Specific welding procedures, techniques, and consumables must be followed. Controlling welding parameters, such as heat input, current, and voltage, is vital to ensure proper fusion and minimize distortion. 5. Weld Quality: The quality of welds is paramount. Welds must be free from defects, including cracks, porosity, or incomplete fusion, as these can compromise structure strength and durability. Non-destructive testing methods, such as visual inspection, ultrasonic testing, or radiography, may be necessary to assess weld quality. 6. Surface Preparation and Coating: Prior to welding, proper surface preparation is necessary for good weld quality. This involves removing contaminants like rust, oil, or paint from the steel surface. Suitable cleaning methods, such as grinding or sandblasting, are essential for proper adhesion and to prevent weld defects. Additionally, appropriate coating systems should be applied to protect against corrosion. 7. Inspection and Quality Control: Implementing regular inspection and quality control measures throughout the fabrication process is crucial. This may include visual inspections, dimensional checks, and non-destructive testing to ensure compliance with specified requirements. Promptly addressing any deviations or defects maintains structural integrity. Adherence to these guidelines is pivotal for successful fabrication and welding of steel structural members. By following these principles, the resulting structure will be safe, durable, and capable of withstanding intended loads and environmental conditions.

- Q: What are the advantages of using steel structures in housing construction?

- There are several advantages of using steel structures in housing construction. Firstly, steel is a highly durable and long-lasting material, providing a strong framework for the house. It can withstand extreme weather conditions, such as hurricanes and earthquakes, better than traditional building materials. Secondly, steel is lightweight, making it easier and faster to construct houses using steel structures, reducing construction time and costs. Additionally, steel is a sustainable material as it is recyclable and can be used in multiple projects, reducing environmental impact. Lastly, steel structures offer great design flexibility, allowing for open floor plans and large spans, giving homeowners the freedom to create their desired living spaces.

- Q: What are the considerations for steel structures in areas with high seismic hazards?

- In areas with high seismic hazards, several considerations need to be taken into account for steel structures. Firstly, the design of the structure should comply with the local building codes and regulations that specifically address seismic design requirements. These codes typically provide guidelines on factors such as structural strength, stiffness, and ductility to ensure the structure can withstand seismic forces. Secondly, the selection of appropriate materials is crucial. Steel is commonly used in seismic-resistant structures due to its high strength and ductility. However, the steel must be of high quality and meet specific specifications to ensure its performance during earthquakes. Another consideration is the structural configuration. Steel structures should be designed to have a regular and symmetric layout to distribute seismic forces evenly. Incorporating lateral load-resisting systems like bracing or moment-resisting frames can also enhance the structure's seismic performance. Additionally, proper detailing and connections are essential. Adequate connections between steel members and between the structure and its foundation are necessary to maintain the integrity of the structure during seismic events. Regular inspection, maintenance, and retrofitting of steel structures should also be conducted to ensure their continued safety and integrity in high seismic hazard areas. Overall, the considerations for steel structures in areas with high seismic hazards involve compliance with building codes, material selection, structural configuration, detailing and connections, and ongoing maintenance and retrofitting.

- Q: How does steel compare to other materials in terms of strength?

- Steel is known for its exceptional strength compared to many other materials. It has a higher strength-to-weight ratio than materials like aluminum, wood, and plastic, making it popular in various industries. Steel's strength allows for the construction of sturdy buildings, bridges, and infrastructure, as well as the production of durable tools and equipment.

Send your message to us

Best Quality Solar Bracket

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 3000 watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords