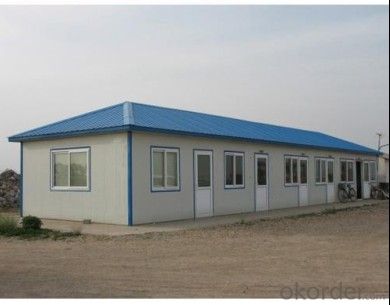

steel structure workshop warehouse building

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Steel structure workshop warehouse building

1. ISO9001:2008, SGS and BV Certification

2. Structural safety and reliability

steel structure workshop warehouse building

Technical Parameters

Item Name | steel structure workshop warehouse building |

Main Material | Q235/Q345 Welded H Beam and Hot Rolled Section Steel |

Surface | Painted or Hot Dip Galvanized |

Roof & Wall Panel | EPS Sandwich panel /Single Corrugated Steel Sheet/ Colour sheet with Glass-wool, for customers choose |

Window | PVC Steel or Aluminum Alloy |

Door | Sliding Door or Rolling Up Door |

Service | Design, Fabrication and Installation |

We can make quotation according to customer's drawing or requirement | |

(size by length/width/height and wind speed), offering a free design | |

drawing and all detailed drawings for installation. | |

Packing | According to customer's requirement |

Load into 40/20GP,40HQ or 40OT |

Packaging Detail:According to container size,container of 20 feet:Inside capacity is 5.69m x 2.34m x 2.18m,Gross weight of allocation is generally 17.5 ton,volumn is 24-26m3. container of 40 feet:Inside capacity is 11.8m x 2.34m x 2.18m,Gross weight of allocation is generally 22 ton,volumn is 54m3. HC container of 45 feet:Inside capacity is 13.58m x 2.34m x 2.71m,Gross weight of allocation is generally 29 ton,volumn is 86m3.Delivery Detail:30 days.

- Q: What are the considerations for designing steel structures for architectural aesthetics?

- When designing steel structures for architectural aesthetics, there are several key considerations to keep in mind. Firstly, the overall form and shape of the structure should be carefully considered to ensure it aligns with the desired aesthetic goals. This includes selecting appropriate proportions, curves, or angles that complement the architectural style. Secondly, the choice of materials and finishes is crucial in achieving the desired aesthetic. Steel can be left exposed to showcase its industrial appeal or coated with various finishes, such as paint or powder coatings, to blend harmoniously with the surrounding environment or architectural theme. Additionally, the detailing and connections of the steel elements play a significant role in the overall aesthetics. Attention should be given to the junctions, welds, and fasteners to ensure they are visually pleasing and seamlessly integrated into the design. Lighting is another consideration that can greatly enhance the aesthetic appeal of steel structures. Strategic placement of lighting fixtures can highlight the structure's features and create dramatic effects, illuminating the steel elements and showcasing their beauty. Lastly, the integration of landscaping and other complementary elements should be taken into account. Incorporating greenery, water features, or other natural elements can soften the industrial feel of the steel and create a more visually appealing and harmonious design. In conclusion, when designing steel structures for architectural aesthetics, considerations should include form and shape, choice of materials and finishes, detailing and connections, lighting, and integration with the surrounding environment. By carefully addressing these factors, an architect can create steel structures that not only meet functional requirements but also offer visually pleasing and aesthetically satisfying designs.

- Q: How does steel perform in terms of thermal insulation?

- Steel is not a good thermal insulator as it has high thermal conductivity, meaning it easily transfers heat and cold. Therefore, steel is not an effective material for providing insulation against temperature fluctuations.

- Q: How do steel structures perform in terms of flexibility for future modifications?

- Steel structures are highly flexible and can easily accommodate future modifications. Due to their inherent strength and versatility, steel structures can be easily expanded, reconfigured, or modified as per the changing needs and requirements of the space. This flexibility allows for efficient adaptations and renovations, making steel structures a preferred choice in various industries.

- Q: What are the cost considerations for steel structures?

- Cost considerations for steel structures depend on various factors, including the size and complexity of the project, the type and quality of steel used, and the location of the construction site. One of the major cost considerations for steel structures is the upfront investment required. Steel is generally more expensive than other construction materials such as wood or concrete. However, steel structures offer numerous long-term benefits, such as durability, strength, and resistance to environmental factors, which can offset the initial cost. Another cost consideration is the fabrication and installation expenses. Steel structures often require skilled labor for fabrication and erection, which can add to the overall project cost. Additionally, the transportation of steel components to the construction site can also contribute to the expenses. Maintenance and repair costs should also be taken into account. While steel structures are known for their durability, regular maintenance is necessary to ensure their longevity. This includes inspections, painting, and addressing any potential issues or damages. These maintenance costs should be factored into the overall budget. The location of the construction site can impact the cost of steel structures. If the site is in a remote or inaccessible area, transportation costs for steel components may increase. Similarly, if the site is prone to extreme weather conditions, additional measures may need to be taken to ensure the structural integrity of the steel building, which can add to the expenses. It is also important to consider the potential for cost savings in terms of time and labor when using steel structures. The speed of construction with steel allows for faster project completion, which can result in reduced labor costs. Additionally, steel structures are often prefabricated off-site, minimizing on-site construction time and potential disruptions. In conclusion, the cost considerations for steel structures encompass factors such as the initial investment, fabrication and installation expenses, maintenance and repair costs, location-specific considerations, and potential time and labor savings. By carefully analyzing these factors, project owners can make informed decisions about the cost-effectiveness of steel structures for their specific needs.

- Q: How are steel structures used in shipbuilding and marine facilities?

- Due to their high strength, durability, and resistance to corrosion, steel structures find extensive use in shipbuilding and marine facilities. These structures serve as the backbone of ships, offering support to various components and systems. In shipbuilding, steel is employed to construct the primary hull, decks, bulkheads, and superstructures of the vessel. The hull, which comprises welded steel plates, forms a watertight enclosure and provides the ship with strength and stability to navigate through rough seas and withstand extreme weather conditions. Steel structures are also utilized to build the ship's floors, known as decks, and the vertical walls that divide it into compartments, known as bulkheads. These structures add further strength and support to the overall framework of the ship, ensuring its integrity and safety. Furthermore, steel is utilized in the construction of superstructures, which encompass the upper sections of the ship above the main deck. These superstructures encompass cabins, bridge towers, and other amenities for the crew and passengers. Steel's high strength-to-weight ratio is favorable for constructing spacious areas while minimizing the overall weight of the ship. In marine facilities like ports, piers, and offshore platforms, steel structures play a vital role in providing support and stability. Steel is employed in constructing pilings, beams, and trusses, which form the foundation and framework of these structures. The superior strength and durability of steel make it well-suited to endure the harsh marine environment, including the corrosive effects of saltwater and constant exposure to waves and tides. In summary, steel structures are indispensable in shipbuilding and marine facilities, ensuring the safety and longevity of ships and marine structures by offering the necessary strength, durability, and resistance to corrosion.

- Q: How do steel structures contribute to the overall architectural expression of a building?

- Steel structures contribute to the overall architectural expression of a building by providing a strong and durable framework that allows for larger and more intricate designs. The use of steel allows for greater flexibility in architectural design, as it can support wide spans and open floor plans. Additionally, steel structures can be shaped and formed into various aesthetic configurations, giving architects more creative freedom in their designs. The sleek and modern appearance of steel also adds a contemporary and industrial element to the building's overall look and feel.

- Q: What are the design considerations for steel retail buildings?

- Some design considerations for steel retail buildings include structural stability, flexibility for future expansions or modifications, efficient use of space, proper lighting and ventilation, aesthetic appeal, and compliance with building codes and regulations. Additionally, factors such as durability, cost-effectiveness, and sustainability may also be taken into account during the design process.

- Q: How are steel plates and gussets designed and installed?

- Steel plates and gussets are commonly used in construction and engineering projects to provide additional strength and support to various structures. These components are designed and installed following a specific process to ensure their effectiveness and durability. The design of steel plates and gussets starts with determining the required dimensions and thickness based on the specific load and structural requirements of the project. Engineers use various design codes and calculations to determine the appropriate size and shape of these components. Once the design is finalized, the fabrication of steel plates and gussets begins. This involves cutting and shaping the steel material according to the specified dimensions. This can be done using various methods such as laser cutting, plasma cutting, or traditional mechanical methods like sawing and drilling. After the fabrication process, the plates and gussets are typically prepared for installation by cleaning and priming the surfaces to prevent corrosion. This is particularly important for outdoor or exposed structures. During installation, the plates and gussets are attached to the structural members using various fastening techniques. This can include welding, bolting, or riveting, depending on the specific requirements and design of the project. Welding is a common method used, especially for larger and heavier plates and gussets. Bolting and riveting are more frequently used for smaller and lighter components. Proper alignment and positioning of the steel plates and gussets is crucial during installation to ensure they are placed correctly and securely. This is done by using alignment tools, such as levels and plumb bobs, to ensure accurate placement. It is also important to consider factors such as load distribution and stress transfer when installing steel plates and gussets. Engineers and contractors need to carefully analyze the structural requirements and consider how these components will affect the overall performance and stability of the structure. In summary, the design and installation of steel plates and gussets involve a meticulous process that includes determining the appropriate dimensions, fabricating the components, preparing the surfaces, and securely attaching them to the structural members. Following these steps ensures that the plates and gussets effectively strengthen the structure and contribute to its overall stability and safety.

- Q: How are steel structures designed for loading docks?

- Steel structures for loading docks are designed to provide a strong and durable framework that can withstand heavy loads and repetitive use. Engineers consider factors such as the weight and size of the loads being handled, the frequency of loading and unloading, and the overall layout and functionality of the dock. The design includes components such as beams, columns, and bracing to ensure stability and support. Additionally, safety measures such as non-slip surfaces and proper lighting are incorporated into the design to enhance the efficiency and safety of the loading dock operations.

- Q: What is the difference between a steel structure and a steel warehouse?

- A steel structure refers to a construction made entirely or primarily out of steel, which can include buildings, bridges, or other infrastructure. On the other hand, a steel warehouse specifically refers to a building designed and constructed for storing goods or materials, typically made out of steel for its durability and strength. In summary, a steel structure is a broader term encompassing various steel constructions, while a steel warehouse is a specific type of steel structure designed for storage purposes.

Send your message to us

steel structure workshop warehouse building

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords