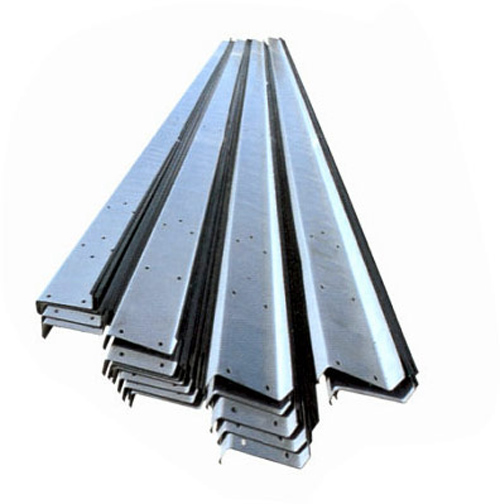

Z Channel Steel Bar

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

In architecture, structural engineering or building, a purlin (or historically purline, purloyne, purling, perling) is any longitudinal, horizontal, structural member in a roof except a type of framing with what is called a crown plate. In traditional timber framing there are three basic types of purlin: purlin plate, principal purlin and common purlin.

Specifications:

1)Price:FOB $500-650

2)Material:Q195-Q420,Q195,Q215,Q235,Q345

3)Certification:ISO9001, SGS, BV

4)Payment term:TT,L/C

Advantages and features:

1.Light,good strength,cauterization resistance and water resistance;

2.Matching magnesium fire-proof board,gypsum board,and many other wall and ceiling board;

3.Moisture -proof,shock-resistance,high-effecient,environmentally-friendly and so on;

4.Easy and fast for installation,time-saving;

5.prompt delivery,high quality,competitive price and complete sets of style;

6.We can supply you the products based on your specific requirements;

- Q: The steel structure housing about how much money.

- The price of steel structure are relatively expensive, one square meter is about 500 to 600 yuan, in general, the temporary office with color steel structures on the line, health economics, now some large construction sites are using this board, the effect is good, it is recommended that you use!

- Q: What is the role of steel in insulation and energy efficiency?

- Steel does not directly contribute to insulation and energy efficiency. However, it is commonly used in the construction of energy-efficient buildings due to its strength and durability, which allows for the creation of well-insulated structures. Steel is often incorporated into the framework of buildings, providing stability and support for insulation materials, such as foam or fiberglass, which are responsible for the actual insulation and energy efficiency.

- Q: How are steel structures designed for vibration control?

- Steel structures can be designed for vibration control by incorporating various techniques such as damping systems, vibration isolators, and tuned mass dampers. These methods aim to reduce the dynamic response of the structure to external forces and minimize the transmission of vibrations. Additionally, computer simulations and analysis can be conducted to optimize the design and ensure the structure's ability to withstand vibrations.

- Q: How are steel structures designed for power plants?

- When designing steel structures for power plants, several important factors are taken into consideration. Firstly, the structural design must be capable of supporting the heavy machinery and equipment used in power generation, such as turbines, boilers, and generators. These components can be exceptionally large and require sturdy and stable foundations. Another crucial aspect of the design is ensuring that the steel structure can withstand the different loads and forces present in power plants. These loads may include static loads like the weight of the equipment, as well as dynamic loads like vibrations and seismic forces. The structure must be able to resist these loads and provide a secure and stable environment for the power plant's operation. Furthermore, steel structures for power plants must also account for factors like thermal expansion and contraction. The equipment used in power generation produces high temperatures, which can cause the steel structure to expand and contract. The design must consider these movements to prevent any structural damage or failure. Fire safety is another essential consideration in the design. Power plants contain flammable materials and have the potential for fires. Steel structures are designed to be fire-resistant, incorporating appropriate fireproofing materials and insulation to prevent the spread of fire and ensure the safety of personnel and equipment. Lastly, the design of steel structures in power plants also takes into account factors like accessibility for maintenance and repairs. Power plants require regular inspections, maintenance, and possible equipment replacements. The design should facilitate easy access to different areas of the structure, ensuring these activities can be carried out efficiently and effectively, thereby promoting the longevity and efficiency of the power plant. In conclusion, when designing steel structures for power plants, several considerations are made to support heavy equipment, withstand various loads and forces, account for thermal expansion and contraction, provide fire safety, and allow for easy maintenance and repairs. These considerations are vital for ensuring the safe and efficient operation of power plants.

- Q: How are steel structures used in transportation infrastructure?

- Steel structures are commonly used in transportation infrastructure due to their strength, durability, and versatility. They are used in the construction of bridges, tunnels, railway tracks, and airport terminals, among others. Steel's high load-bearing capacity allows for the construction of large and long-span structures, ensuring the safety and efficiency of transportation systems. Additionally, steel structures can be prefabricated, enabling faster construction and reducing disruption to traffic flow during infrastructure projects.

- Q: How are steel structures designed to accommodate for vibration?

- Steel structures are designed to accommodate for vibration through various techniques and considerations. One of the primary methods is to ensure that the structure has sufficient stiffness and strength to resist the dynamic forces generated by vibrations. This is achieved by using appropriate structural elements, such as beams, columns, and bracing, that are designed to have the required rigidity and durability. Another important aspect is the damping of vibrations. Damping refers to the dissipation of energy from the vibrating system, which helps reduce the amplitude of the vibrations. Steel structures can incorporate damping mechanisms, such as tuned mass dampers or viscoelastic materials, to absorb and dissipate the energy generated by vibrations. These dampers act as energy sinks and reduce the overall vibration levels. Furthermore, the design of steel structures takes into account the frequency of the vibrations. By analyzing the potential sources of vibration, engineers can determine the natural frequencies at which the structure is likely to resonate. To avoid resonance, the design can incorporate measures such as altering the stiffness or mass distribution of the structure, or introducing additional damping elements. Additionally, steel structures can be designed with flexible connections to accommodate for vibrations. These connections allow for some movement and flexibility, which helps dissipate the energy generated by vibrations. By allowing controlled movement, the structure can better withstand and absorb the dynamic forces caused by vibrations. Lastly, during the design process, engineers consider the potential sources of vibration, such as machinery, equipment, or environmental factors, and assess their impact on the structure. They also perform detailed dynamic analysis and modeling to ensure that the structure can withstand and safely accommodate the expected vibrations. In summary, steel structures are designed to accommodate for vibration through techniques such as increasing stiffness and strength, incorporating damping mechanisms, considering resonance frequencies, using flexible connections, and analyzing the impact of potential vibration sources. These measures ensure that the structure can safely withstand vibrations and maintain its integrity and functionality.

- Q: How do steel structures provide resistance against soil settlement?

- Steel structures provide resistance against soil settlement by distributing the load evenly over a larger surface area. The strength and rigidity of steel help to prevent excessive settlement by minimizing the impact of soil movement or settlement on the structure. Additionally, steel structures can be designed with deep foundations, such as piles or caissons, which can reach more stable soil layers and provide additional support to resist settlement.

- Q: What are the different types of steel frames used in building structures?

- Building structures make use of various types of steel frames, each possessing their own distinct properties and advantages. Some commonly utilized variants encompass: 1. Traditional Steel Frames: These frames consist of hot-rolled sections and find extensive use in low to mid-rise constructions. Their exceptional strength and durability render them appropriate for a wide array of applications. 2. Light Gauge Steel Frames: Thin steel sheets, typically less than 3mm in thickness, constitute this frame type. They are lightweight and easy to manage, making them ideal for residential and commercial structures. Moreover, light gauge steel frames exhibit remarkable resistance against fire, corrosion, and pests. 3. Composite Steel Frames: These frames combine steel with other materials, like concrete, in order to create structures that are more efficient and cost-effective. By leveraging the advantages of both materials, composite frames offer high strength, flexibility, and fire resistance. 4. Pre-engineered Steel Frames: Frames of this nature are manufactured off-site and subsequently assembled on-site. They are specifically designed to meet unique building requirements and can be customized to accommodate diverse architectural designs. Pre-engineered steel frames are typically employed in warehouses, factories, and other industrial constructions. 5. Modular Steel Frames: Comprising prefabricated sections that are produced away from the construction site and then assembled on-site, modular steel frames offer expeditious installation and flexible design and layout options. They are commonly employed in commercial and residential buildings, as well as temporary structures. 6. Steel Moment Frames: These frames are engineered to withstand lateral loads caused by phenomena like earthquakes or strong winds. Possessing excellent ductility, steel moment frames can absorb and dissipate substantial amounts of energy, making them suitable for high-rise buildings and structures located in seismic zones. The aforementioned examples merely scratch the surface of the diverse range of steel frames utilized in building structures. The selection of an appropriate frame type hinges on factors such as the building's purpose, height, location, and desired levels of strength, durability, and sustainability.

- Q: What are the different types of steel foundations?

- There are several types of steel foundations commonly used in construction, including driven piles, helical piles, micropiles, and drilled shafts. Each type has its own unique characteristics and is chosen based on factors such as soil conditions, load requirements, and project specifications.

- Q: What are the guidelines for the fabrication and welding of steel structural members?

- The guidelines for the fabrication and welding of steel structural members are essential to ensure the integrity, safety, and performance of the structure. These guidelines involve several key aspects that need to be considered during the fabrication and welding process. 1. Material Selection: The first step in the fabrication process is selecting the appropriate steel material for the structural members. The chosen steel should meet the required specifications, including strength, ductility, and corrosion resistance, as specified by relevant codes and standards. 2. Design and Engineering: The fabrication and welding process should strictly follow the design provided by the structural engineer. The design should include details such as dimensions, tolerances, connections, and welding requirements. It is crucial to ensure that the fabrication process adheres to these design specifications to maintain the structural integrity. 3. Cutting and Shaping: Steel structural members often require cutting and shaping to achieve the desired dimensions and shapes. Guidelines for cutting methods, such as shearing, sawing, or flame cutting, should be followed to ensure accurate and clean cuts. Additionally, appropriate tools and techniques should be used to shape the steel members according to the design requirements. 4. Welding Procedures: Welding is a critical process in the fabrication of steel structural members. It is essential to follow specific welding procedures, including the selection of appropriate welding techniques, such as arc welding or gas welding, and the use of suitable welding consumables. Welding parameters, such as heat input, current, and voltage, must be carefully controlled to ensure proper fusion and minimize distortion. 5. Weld Quality: The quality of welds is of utmost importance in steel structural fabrication. Welds should be free from defects, such as cracks, porosity, or incomplete fusion, as these can compromise the strength and durability of the structure. Non-destructive testing methods, such as visual inspection, ultrasonic testing, or radiography, may be required to assess the quality of the welds. 6. Surface Preparation and Coating: Before welding, proper surface preparation is necessary to ensure good weld quality. This involves removing any contaminants, such as rust, oil, or paint, from the steel surface. The use of suitable cleaning methods, such as grinding or sandblasting, is essential to achieve proper adhesion and prevent defects in the weld. Additionally, appropriate coating systems should be applied to protect the steel members from corrosion. 7. Inspection and Quality Control: Regular inspection and quality control measures should be implemented throughout the fabrication process. This may involve visual inspections, dimensional checks, and non-destructive testing to ensure compliance with the specified requirements. Any deviations or defects should be addressed promptly to maintain the structural integrity of the members. Adhering to these guidelines is crucial for the successful fabrication and welding of steel structural members. By following these principles, the resulting structure will be safe, durable, and capable of withstanding the intended loads and environmental conditions.

Send your message to us

Z Channel Steel Bar

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches