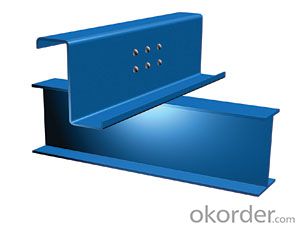

Prepainted Z Channel Steel Bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 30000 watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description

1.Thickness:0.5mm to 4mm.

2.Grade:Q235,Q345.

3.Width:80mm to 300mm.

4.Material:Galvanized/prepaint

Specifications

1) Manufactured from high tensile galvanized steel

2) Despotic C&Z section steel, Z section steel is roll-formed from galvanized steel, specification to be complete

3) Make from quality raw material

4) Pre-punched holes based on detail design

5) Complete accessories package available

6) C purlin, Z purlin and H beam are widely used in factory buildings, large-span bridges, gymnasiums and portable houses

7) C purlin may be used in single spans and continuous spans in multi-bay buildings

8) We can make adjustment to meet your inquiries as we can do

Delivery and package

Delivery Time | 15-25 days after receipt of down payment |

Port | Xingang Port, Tianjin, China |

Packing: | 2ton/boundle with 5 steel strip.if you have any other requirement, it’s possible. The size of container: The inner size of container is below: 20 ft GP:5.8m(length)x 2.13m(width)x 2.18m(high) about 24-26 CBM 40 ft GP:11.8m(length)x 2.13m(width)x 2.72m(high)about 68 CBM |

- Q: What are the design considerations for steel parking structures?

- Design considerations for steel parking structures include: 1. Structural Integrity: Steel parking structures must be designed to withstand the weight of multiple vehicles and the dynamic loads caused by movement and vibrations. The structural system should be robust and able to resist impacts, wind loads, and seismic forces. 2. Space Efficiency: Parking structures need to maximize the number of parking spaces within the available area. The design should minimize wasted space, optimize parking layouts, and incorporate efficient circulation patterns for vehicles and pedestrians. 3. Durability: Steel parking structures should be designed to resist corrosion and degradation over time. Proper surface coatings, corrosion protection measures, and maintenance protocols must be implemented to ensure the longevity and safety of the structure. 4. Fire Safety: Fire safety is a critical consideration for parking structures. The design should incorporate fire-resistant materials, adequate fire suppression systems, and safe egress routes for occupants. Additionally, the structure should facilitate easy access for firefighting equipment. 5. Lighting and Ventilation: Proper lighting and ventilation are crucial for user comfort and safety. Adequate natural and artificial lighting, as well as effective ventilation systems, should be incorporated to create a pleasant and secure environment for both drivers and pedestrians. 6. Accessibility: Steel parking structures should be designed to accommodate individuals with disabilities, ensuring accessible parking spaces, ramps, elevators, and signage comply with applicable regulations. 7. Environmental Impact: Sustainable design practices should be considered to minimize the environmental impact of parking structures. This may include incorporating green building techniques, rainwater harvesting, energy-efficient lighting, and the use of recycled materials. 8. Aesthetics: The design of parking structures should also consider the visual impact on the surrounding area. The structure should blend harmoniously with the overall architectural context, using aesthetically pleasing materials, colors, and facade treatments. 9. Security: Security measures should be integrated into the design, including surveillance systems, access control, and adequate lighting to enhance user safety and deter criminal activities. 10. Cost-effectiveness: The design should balance functionality, durability, and aesthetics with the available budget. Efficient use of materials, construction methods, and maintenance considerations should be factored in to ensure cost-effectiveness throughout the lifespan of the structure.

- Q: How are steel structures used in chemical processing plants?

- Due to their strength, durability, and resistance to corrosion, steel structures find extensive use in chemical processing plants. These structures are specifically designed to withstand the harsh and demanding environments encountered in these plants, supporting heavy equipment, piping systems, and storage tanks. One of the primary applications of steel structures in chemical processing plants involves the construction of support platforms and walkways. These platforms enable workers to safely inspect and maintain equipment, while also facilitating efficient movement within the plant. Steel is the preferred material for these structures due to its ability to bear heavy loads and support the weight of personnel, equipment, and materials. Another crucial role played by steel structures in chemical processing plants pertains to the construction of storage tanks. Steel tanks are commonly utilized for storing various chemicals, including corrosive substances, due to their resistance to corrosion. These tanks can be designed to withstand extreme conditions, such as high pressure, high temperature, or low temperature, ensuring the safe storage of hazardous materials. Moreover, steel is widely employed in the fabrication of piping systems within chemical processing plants. Steel pipes are known for their strength and ability to withstand high pressures and temperatures, making them ideal for conveying chemicals throughout the plant. Additionally, steel pipes exhibit excellent resistance to corrosion, thereby reducing the risk of leaks and contamination. Furthermore, steel possesses fire-resistant properties, which are of utmost importance in chemical processing plants where flammable materials are present. Steel structures can effectively prevent the spread of fire, thereby creating a safe environment for workers and minimizing the potential damage to equipment and property. In conclusion, steel structures play a crucial role in chemical processing plants by providing support, storage, and transportation solutions. Their strength, durability, resistance to corrosion, and fire-resistant properties make them the preferred choice for ensuring the safety and efficiency of chemical processing operations.

- Q: Can steel structures be designed to be resistant to corrosion from alkaline substances?

- Indeed, it is possible to design steel structures in a manner that makes them resistant to corrosion caused by alkaline substances. One effective method to prevent corrosion involves the utilization of corrosion-resistant coatings, such as specialized metallic coatings like zinc or aluminum, as well as paints. These coatings act as a protective barrier between the steel surface and the alkaline substances, effectively preventing direct contact and corrosion. Moreover, stainless steel can also be employed as a construction material. Stainless steel possesses chromium, which forms a protective layer on its surface known as a passive film. This passive film serves as a robust barrier against corrosion, even when exposed to alkaline substances. Furthermore, the design of the steel structure itself can significantly contribute to corrosion prevention. Implementing proper drainage systems, preventing water stagnation, and ensuring sufficient ventilation can aid in reducing the steel structure's exposure to alkaline substances. Additionally, paying attention to proper detailing and design considerations, such as avoiding crevices and minimizing points where water can accumulate, can also enhance the steel structure's resistance to corrosion. It is important to note that while these measures can greatly enhance the corrosion resistance of steel structures against alkaline substances, regular maintenance and inspections are still necessary to ensure their long-term durability and performance.

- Q: How are steel structures connected?

- Steel structures are typically connected through various methods such as welding, bolting, and riveting. Welding is one of the most common methods used to connect steel components. It involves melting the edges of the steel pieces and fusing them together using heat and pressure. Welding provides a strong and permanent connection, making it ideal for structural applications. Bolting is another commonly used method of connecting steel structures. Bolts are inserted through pre-drilled holes in the steel components and tightened with nuts to create a secure connection. Bolting allows for easy disassembly and reassembly, making it suitable for applications where flexibility is required. Riveting is an older method that is still used in certain applications. It involves inserting a hot rivet into pre-drilled holes in the steel components and then hammering it to create a tight connection. While riveting is not as common as welding or bolting, it is still used in situations where aesthetics or historical accuracy are important. In addition to these primary methods, other techniques such as adhesive bonding and mechanical connectors can also be employed to connect steel structures. Adhesive bonding involves using epoxy or other bonding agents to attach steel components together, while mechanical connectors utilize specialized devices to join steel pieces. The choice of connection method depends on factors such as the load requirements, structural design, and the specific application of the steel structure. Each method has its advantages and disadvantages, and engineers must carefully consider these factors to ensure the safety, durability, and functionality of the steel structure.

- Q: How are steel structures designed for power plants and industrial facilities?

- Steel structures for power plants and industrial facilities are designed with careful consideration of the specific requirements and demands of these environments. The design process typically involves a thorough analysis of the site conditions, loads, and safety regulations. Engineers use advanced software and techniques to ensure the structural integrity, durability, and efficiency of the steel structures. Factors such as seismic activity, temperature variations, and corrosion resistance are also taken into account to ensure long-term performance and reliability.

- Q: How are steel structures designed for heavy equipment loads?

- Steel structures designed for heavy equipment loads are typically engineered to withstand the specific weight and forces exerted by the equipment. This involves carefully calculating and determining the required steel sections, connections, and reinforcements to ensure the structure's stability and durability under such loads. Factors such as the type and magnitude of the equipment loads, the span and height of the structure, as well as the local building codes and safety standards, are taken into consideration during the design process. Additionally, computer-aided design (CAD) software and structural analysis tools are commonly utilized to optimize the design and ensure the structure can safely support the heavy equipment loads.

- Q: What are the considerations for aesthetic design in steel structures?

- When it comes to aesthetic design in steel structures, there are several important considerations to take into account. Firstly, the overall appearance and visual appeal of the structure should be considered. This includes factors such as the shape, form, and proportions of the steel elements. Attention should be given to creating an aesthetically pleasing design that harmonizes with the surrounding environment or architectural style. Another consideration is the choice of materials and finishes. Steel structures can be finished with various coatings, such as paint or galvanization, to enhance their visual appearance and protect them from corrosion. The choice of color and texture can significantly impact the overall aesthetic appeal of the structure. Additionally, the detailing of the steel elements plays a crucial role in the aesthetic design. Attention to details such as joints, connections, and transitions between different steel members can greatly influence the visual quality of the structure. The use of decorative elements or architectural features can also add visual interest and enhance the overall design. Furthermore, the integration of lighting can greatly enhance the aesthetic appeal of steel structures. Strategic placement of lighting fixtures can highlight the architectural features and create a visually stunning effect during nighttime. Lastly, it is important to consider the context and purpose of the steel structure. The design should align with the intended use of the structure, whether it is a commercial building, bridge, or public art installation. The aesthetic design should also take into account any specific requirements or regulations, such as safety considerations or accessibility standards. In conclusion, the considerations for aesthetic design in steel structures encompass the overall appearance, choice of materials and finishes, detailing, integration of lighting, and alignment with the context and purpose of the structure. By carefully considering these factors, a visually appealing and harmonious steel structure can be achieved.

- Q: What are the different types of steel cladding and facade systems used in buildings?

- There are several different types of steel cladding and facade systems that are commonly used in buildings. These systems are chosen based on factors such as the building's design, aesthetics, durability, and budget. Here are some of the most common types: 1. Steel Panels: Steel panels are one of the most popular choices for cladding and facade systems. They are available in various shapes, sizes, and finishes, allowing for a wide range of design possibilities. Steel panels are durable, low maintenance, and can be easily installed. 2. Steel Mesh: Steel mesh cladding is a versatile system that can be used to create unique and visually appealing facades. It consists of a grid of steel wires or bars that are woven or welded together. Steel mesh offers transparency, allowing for natural light and ventilation while providing a modern and industrial aesthetic. 3. Corrugated Steel Sheets: Corrugated steel sheets are commonly used for cladding and facade systems in industrial and agricultural buildings. They are lightweight, cost-effective, and provide excellent strength and durability. Corrugated steel sheets are available in different profiles and can be coated with various finishes for enhanced aesthetics. 4. Perforated Steel Panels: Perforated steel panels are widely used for both cladding and facade systems. They are designed with small holes or patterns that allow for ventilation and light transmission while maintaining privacy and security. Perforated steel panels can be customized to create unique and intricate designs. 5. Stainless Steel Cladding: Stainless steel cladding offers a high-end and sleek appearance to buildings. It is highly durable, corrosion-resistant, and requires minimal maintenance. Stainless steel cladding is often used in commercial and high-end residential buildings to achieve a modern and luxurious aesthetic. 6. Standing Seam Systems: Standing seam systems are a popular choice for roof and wall cladding. They consist of interlocking metal panels that create a continuous seam, providing excellent weather resistance and durability. Standing seam systems can be made from various metals, including steel, aluminum, and copper, offering a wide range of design options. 7. Composite Panels: Composite panels are a combination of steel and other materials, such as aluminum or fiberglass, bonded together to create a lightweight and highly insulating cladding system. These panels offer excellent thermal performance, fire resistance, and are available in a variety of finishes and colors. These are just a few examples of the different types of steel cladding and facade systems used in buildings. Each system has its own advantages and can be chosen based on the specific requirements of the project.

- Q: How do steel structures resist corrosion?

- Steel structures resist corrosion through a process called passivation, which involves the formation of a thin, protective layer of oxide on the surface of the steel. This layer acts as a barrier, preventing oxygen and moisture from reaching the underlying metal and causing corrosion. Additionally, steel structures can be further protected through methods such as galvanization, coating with paints or sealants, and regular maintenance to repair any damaged or exposed areas.

- Q: How are steel structures designed to accommodate architectural glazing systems?

- Steel structures are designed to accommodate architectural glazing systems through careful engineering and collaboration between structural and glazing professionals. This involves considering factors such as load-bearing capabilities, wind and seismic forces, thermal expansion, and the overall aesthetic requirements. Steel frames are specifically designed to provide the necessary support and anchorage for glazing systems, ensuring their safety, durability, and seamless integration within the overall architectural design.

Send your message to us

Prepainted Z Channel Steel Bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 30000 watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords