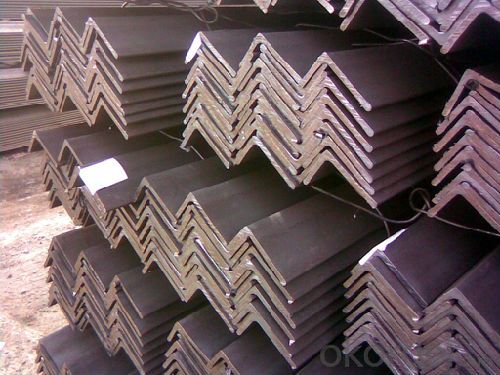

Hot rolled steel angle steel angle for constrution

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Hot rolled steel angle steel angle for constrution at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Hot rolled steel angle steel angle for constrution are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's steel angle are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Specifications

1) . Easy to install, fire proof, good insulation

2). Certification: ISO9001:2000, SGS Standard.

Steel Structure Warehouse:

1.The steel structure of the connection method: welding connection

2.Steel structure design common norms are as follows: "Steel Design Code" (GB50017-2003) Cold-formed steel structure technical specifications" (GB50018-2002) "Construction Quality Acceptance of Steel" (GB50205-2001) "Technical Specification for welded steel structure" (JGJ81-2002, J218-2002) "Technical Specification for Steel Structures of Tall Buildings" (JGJ99-98)

3.The characteristics of steel Light weight steel structure Higher reliability of steel work Steel anti-vibration (earthquake), impact and good Steel structure for a higher degree of industrialization Steel can be assembled quickly and accurately Large steel interior space Likely to cause sealing structure Steel corrosive Poor fire-resistant steel Recyclable steel shorter duration

4.Commonly used steel grades and performance of steel Carbon

structural steel: Q195, Q215, Q235, Q255, Q275, etc.

High-strength low-alloy structural steel Quality carbon structural steel and alloy structural steel Special purpose steel Product Feature Carport, House, Office, Shop, Toilet, Villa, Warehouse, Workshop, Plant Other Information

Products have been all over the country more than 20 provinces, municipalities and autonomous regions, and have been exported to Europe, North America, the Middle East, Africa, Asia and other countries and regions, the widespread use

Welcome to our factory, we assure that our products will satisfy your needs with designs, competitive performance price ratio and best services.

FAQ:

Q1: How do we guarantee the quality of our products?

A1: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q2: How soon can we receive the product after purchase?

A2: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

- Q: What are the key considerations in the design of steel structures for recreational facilities?

- Some key considerations in the design of steel structures for recreational facilities include the intended use and function of the facility, the potential loads and stresses it will experience, the aesthetics and desired architectural style, the local climate and weather conditions, and the budget and timeline constraints. Additionally, factors such as safety, durability, maintenance requirements, and sustainability should also be taken into account during the design process.

- Q: How do steel structures perform in terms of fire resistance?

- Steel structures generally have excellent fire resistance. Unlike other materials, such as wood or concrete, steel does not burn or contribute to the spread of fire. Instead, it retains its strength and integrity at high temperatures, which allows steel structures to withstand fire for a longer period of time without collapsing. Additionally, steel has a high melting point, further enhancing its fire-resistant properties. However, prolonged exposure to extreme heat can eventually weaken steel, so fire protection measures like insulation or fireproof coatings are often applied to enhance the fire resistance of steel structures.

- Q: What are the advantages of using lightweight steel structures?

- One advantage of using lightweight steel structures is their durability and strength. Despite their lightweight nature, these structures are capable of withstanding heavy loads and adverse weather conditions. Additionally, they have a longer lifespan compared to traditional building materials like wood or concrete. Another advantage is their versatility and ease of construction. Lightweight steel structures can be easily customized and modified, making them suitable for a wide range of applications such as residential, commercial, and industrial buildings. Moreover, these structures are typically prefabricated, allowing for faster and more efficient construction processes. Finally, lightweight steel structures are environmentally friendly as they are often made from recycled materials and can be easily recycled at the end of their life cycle.

- Q: How do steel structures handle heavy loads?

- Steel structures are able to handle heavy loads due to the inherent strength and durability of steel as a construction material. Steel has a high strength-to-weight ratio, meaning it can support large amounts of weight while remaining relatively lightweight itself. Additionally, steel's flexibility allows it to distribute and absorb heavy loads effectively, preventing structural failure. Steel structures also benefit from their ability to be designed and fabricated to precise specifications, ensuring that they can withstand the anticipated loads and stresses placed on them.

- Q: What does "HW350x350" mean in steel structures?

- Hot rolled wide flange steel H symbols, web height 350, flange width 350

- Q: How are steel structures used in the construction of amusement parks?

- Steel structures are widely used in the construction of amusement parks due to their strength, durability, and versatility. They play a crucial role in providing the necessary support and stability for various amusement park rides and attractions. One of the primary uses of steel structures in amusement parks is for roller coasters. Steel allows for the creation of complex and intricate track designs, enabling roller coasters to twist, turn, and loop in ways that would not be possible with other materials. The high strength-to-weight ratio of steel ensures the safety and stability of these thrilling rides. Steel is also utilized in the construction of other major attractions like Ferris wheels, drop towers, and observation towers. These structures require a strong and stable foundation to withstand the forces exerted on them, and steel provides the necessary strength and rigidity to support these tall and dynamic rides. In addition to supporting the rides themselves, steel structures are used for various support systems within amusement parks. This includes platforms, walkways, staircases, and bridges that allow visitors to access different areas of the park and safely navigate around the rides. Steel's strength and versatility make it an ideal material for constructing these structures, ensuring the safety and comfort of park visitors. Furthermore, steel structures are often used for the construction of park entrance gates, ticket booths, and other architectural elements. Steel's aesthetic appeal, along with its durability and ease of maintenance, make it a popular choice for creating visually appealing and long-lasting structures that welcome visitors to the amusement park. Overall, steel structures are essential in the construction of amusement parks as they provide the necessary strength, stability, and versatility to support and enhance the various rides, attractions, and architectural elements. With their exceptional properties, steel structures contribute to the overall safety, functionality, and aesthetic appeal of these exciting entertainment complexes.

- Q: How do steel structures handle soil settlement and subsidence?

- Steel structures are able to handle soil settlement and subsidence by being designed to accommodate these movements. Firstly, steel structures are often built on deep foundations, such as piles, that can withstand the settlement and subsidence of the soil. Additionally, steel is a flexible material that can tolerate some degree of movement without significant damage or structural failure. This flexibility allows the steel structure to distribute the load evenly, minimizing the impact of soil movement. Moreover, steel structures can be designed with adjustable connections and joints that can be tightened or loosened to adapt to the changing conditions of the soil. Overall, steel structures are engineered to be resilient and adaptable, making them well-suited to withstand soil settlement and subsidence.

- Q: What are the different methods of steel structure fire protection?

- There are several methods of fire protection for steel structures, including the use of fire-resistant coatings, spray-applied fireproofing, and intumescent coatings. Fire-resistant coatings are typically applied to the surface of the steel to provide a protective shield against heat and flames. Spray-applied fireproofing involves the application of a cementitious material that provides insulation and prevents the steel from reaching high temperatures. Intumescent coatings, on the other hand, expand when exposed to heat, forming a char layer that insulates the steel from the fire. These methods are commonly used to enhance the fire resistance of steel structures and ensure their structural integrity during a fire event.

- Q: How is the steel structure foundation checked and accepted?

- The column position in the column surface measuring axis of projectile.Level of plinth elevation. Concrete plinth elevation 50 ~ 60 mm for general casting (compared with steel column base design, installation in elevation) with steel plate or early adoption by plasma plate leveling.When using the steel plate support plate, steel plate area should be determined according to the fastening force and compressive strength, concrete of foundation base plate two times before grouting at the bottom of the column load and anchor bolt. The contact between the shim and the base and the bottom of the column should be smooth and tight.When the cushion plate is used, the shrinkage free mortar shall be adopted. The strength of the mortar block should be higher than that of the base concrete before the lifting of the column, and the mortar pad should have enough area to meet the requirements of the load.

- Q: What is the role of steel in life cycle assessments?

- The role of steel in life cycle assessments (LCAs) is crucial as it is one of the most widely used materials in various industries. LCAs aim to evaluate the environmental impact of a product or process throughout its entire life cycle, from raw material extraction to end-of-life disposal or recycling. In the case of steel, LCAs consider the different stages of its life cycle, including mining and extraction of iron ore, transportation, steel production, fabrication, usage, and eventual disposal or recycling. Each stage has its own environmental implications, and analyzing these allows for a comprehensive assessment of the steel's overall impact. Steel production, in particular, is a significant contributor to greenhouse gas emissions due to the energy-intensive nature of the process. The extraction of iron ore and the subsequent conversion into steel involve the release of carbon dioxide (CO2) and other greenhouse gases. Additionally, the use of fossil fuels for energy and the consumption of water resources further contribute to the environmental footprint of steel production. However, it is important to note that steel also offers numerous environmental benefits. For instance, steel is highly recyclable, allowing for a reduction in the demand for virgin materials. Recycling steel reduces energy consumption and emissions compared to the production of new steel. Moreover, steel has a long lifespan and is highly durable, making it an efficient and sustainable material choice for various applications. In LCAs, the role of steel is to provide a comprehensive understanding of its environmental impact, allowing for informed decision-making in product design, material selection, and process optimization. By quantifying the environmental burdens associated with steel throughout its life cycle, LCAs help identify areas for improvement and guide the development of more sustainable practices within the steel industry.

Send your message to us

Hot rolled steel angle steel angle for constrution

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches