Pre Drilled Flat Bar

Pre Drilled Flat Bar Related Searches

Forged Aluminum Bar Pre Papered Drywall Continuous Cast Iron Bar Pre Engineered Steel Structure Flat Ducting Anodized Aluminum Flat Bar Stock Aluminum Flat Bar Stock Prefab Villa Pre Made Chain Link Fence Panels Reinforced Concrete With Frp Bars Rigid Industries Light Bar Pre Engineering Steel Structure 1 2 X 3 4 Aluminum Bar Stock Aluminum Stock Bar Stock Aluminum Bar 1 X 2 Aluminum Bar Stock Car Bumper Bar 1 4 X 1 4 Aluminum Bar Stock Prego Flooring Cutting Aluminum Bar Stock Mottled Cast Iron 1 2 X 1 2 Aluminum Bar Stock Prefabricated Housing Modules Dia Bars 1 8 X 1 4 Aluminum Bar Stock Triple Bar Pendant Light Broken Cast Iron 1 Aluminum Bar Stock Ready Made Window Blinds Inhibitor BarPre Drilled Flat Bar Supplier & Manufacturer from China

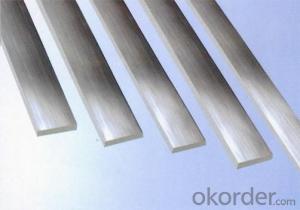

Pre Drilled Flat Bar is a versatile metal product that features evenly spaced holes along its length, providing a convenient and efficient solution for various construction and fabrication projects. This type of flat bar is widely used in applications such as creating frameworks, building structures, and assembling furniture, as the pre-drilled holes allow for quick and easy attachment of other components without the need for additional drilling. The consistent hole spacing and precise dimensions of Pre Drilled Flat Bar make it an ideal choice for professionals and DIY enthusiasts alike.In various usage scenarios, Pre Drilled Flat Bar offers numerous advantages, such as time-saving, cost-effectiveness, and enhanced structural integrity. Its consistent hole pattern simplifies the assembly process, reducing the need for additional measuring and marking, which can lead to errors and delays. Moreover, the pre-drilled holes help ensure that all components are aligned correctly, contributing to a more robust and stable end product. This makes Pre Drilled Flat Bar an essential component in industries such as construction, automotive, and furniture manufacturing.

Okorder.com is a reputable wholesale supplier of Pre Drilled Flat Bar, boasting a large inventory that caters to the diverse needs of customers across different industries. With a commitment to quality and customer satisfaction, Okorder.com ensures that the Pre Drilled Flat Bar they provide meets the highest standards of durability and precision. Their extensive range of Pre Drilled Flat Bar products allows customers to find the perfect fit for their specific project requirements, making Okorder.com a one-stop-shop for all Pre Drilled Flat Bar needs.

Hot Products