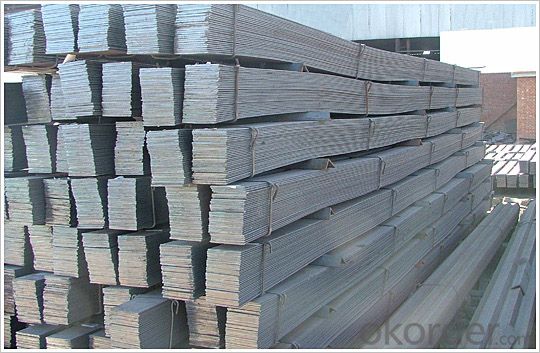

Good Quality Flat Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1) Material: steel

2) Grade: 304, 304L, 316, 316L, 310S, 904L, 2205, B2, C22, 625, etc.

3) Shape: Flat

4) Surface: Black, Hairline, Bright, Polished

5) Finish: Cold drawn, Hot rolled

6) Size:

a) Thickness: 2-20mm

b) Width: 15-200mm

7) Length: 1000mm-12000mm

8) Application: Petroleum & chemical industries, construction field, machinery and hardware fields, food processing and medical industry, high or low temperature resistant, electricity industries, etc.

9) Packing: Standard export packages, custom suffocating free.

10) Min order: 1 ton

11) Origin: China (Mainland)

12) Note: Stainless steel bars/rods can be made according to the customers' requirements.

| Material | 201 | 202 | 304 | 316 | 430 |

C | ≤ 0.15 | ≤ 0.15 | ≤ 0.08 | ≤ 0.08 | ≤ 0.12 | |

Si | ≤ 1.00 | ≤ 1.00 | ≤ 1.00 | ≤ 1.00 | ≤ 1.00 | |

Mn | 5.5-7.5 | 7.5-10 | ≤ 2.00 | ≤ 2.00 | ≤ 1.00 | |

P | ≤ 0.06 | ≤ 0.06 | ≤ 0.045 | ≤ 0.045 | ≤ 0.040 | |

S | ≤ 0.03 | ≤ 0.03 | ≤ 0.030 | ≤ 0.030 | ≤ 0.030 | |

Cr | 16-18 | 17-19 | 18-20 | 16-18 | 16-18 | |

Ni | 3.5-5.5 | 4-6 | 8-10.5 | 10-14 |

| |

Mo |

|

|

| 2.0-3.0 |

| |

| Material Item | 201 | 202 | 304 | 316 | |

Tensile Strength | ≥ 535 | ≥ 520 | ≥ 520 | ≥ 520 | ||

Yield Strength | ≥ 245 | ≥ 205 | ≥ 205 | ≥ 205 | ||

Extension | ≥ 30% | ≥ 30% | ≥ 35% | ≥ 35% | ||

Hardness (HV) | < 253 | < 253 | < 200 | < 200 | ||

- Q: Can steel flat bars be used in food processing industries?

- No, steel flat bars are not typically used in food processing industries as they can corrode over time and contaminate the food. Stainless steel is the preferred material due to its corrosion resistance and hygienic properties.

- Q: How do you prevent pitting or cracking on steel flat bars?

- To prevent pitting or cracking on steel flat bars, there are several measures that can be taken: 1. Proper Storage: Ensure that the steel flat bars are stored in a dry and well-ventilated area to prevent exposure to moisture. Moisture can lead to corrosion and pitting. 2. Protective Coatings: Apply a suitable protective coating on the steel flat bars to create a barrier against moisture and other corrosive elements. Common coatings include paint, varnish, or specialized anti-corrosion coatings. 3. Regular Cleaning: Regularly clean the steel flat bars to remove any dirt, debris, or corrosive substances that might accumulate on the surface. Use mild detergents or specialized cleaning solutions that are safe for steel. 4. Avoiding Impact or Overloading: Handle the steel flat bars with care to prevent any impact or excessive loads that can lead to cracking. Avoid dropping or mishandling the bars during storage, transportation, or installation. 5. Proper Handling and Transportation: When moving or transporting steel flat bars, ensure they are properly secured to prevent any movement or rubbing against each other, which can cause pitting or scratching. 6. Avoid Exposure to Extreme Temperatures: Steel flat bars should be protected from extreme temperatures, especially rapid cooling or heating, as this can cause thermal stress and potential cracking. Allow the bars to gradually acclimate to temperature changes when possible. 7. Regular Maintenance: Inspect the steel flat bars periodically to identify any signs of pitting, cracking, or corrosion. Promptly address any issues by cleaning, repairing, or applying protective coatings as necessary. By implementing these preventive measures, you can minimize the risk of pitting or cracking on steel flat bars, ensuring their longevity and preserving their structural integrity.

- Q: How do you determine the quality of a steel flat bar?

- The quality of a steel flat bar can be determined by considering a few factors. Firstly, the material composition should be examined, including the type of steel used and any additional alloying elements. The manufacturing process and standards followed during production also play a crucial role. Inspecting the surface finish, ensuring it is smooth and free from defects or imperfections, is essential. Additionally, evaluating the dimensions, such as width, thickness, and length, to meet the required specifications is important. Finally, conducting tests for strength, hardness, and resistance to corrosion can further help in assessing the quality of a steel flat bar.

- Q: Are steel flat bars commonly used in the transportation industry?

- Indeed, steel flat bars find widespread usage within the transportation industry. Their application extends to the fabrication of diverse vehicle types, encompassing automobiles, trucks, and trailers. The utilization of steel flat bars yields manifold benefits, primarily in terms of their robustness and resilience, rendering them a prime selection for bolstering substantial burdens and enduring the arduous demands of transport. Furthermore, their malleability and weldability facilitate effortless shaping and joining, thereby affording flexibility in both design and construction. In summary, the indispensable role of steel flat bars in the transportation sector lies in furnishing indispensable structural reinforcement and ensuring the secure and effective conveyance of goods and individuals.

- Q: How do steel flat bars perform in terms of noise reduction?

- Steel flat bars are not specifically designed for noise reduction. They primarily serve as structural components in construction projects.

- Q: Can steel flat bars be used in the manufacturing of agricultural implements?

- Yes, steel flat bars can be used in the manufacturing of agricultural implements. Steel flat bars are a versatile and durable material commonly used in various industries, including agriculture. They offer high strength and rigidity, making them suitable for heavy-duty applications. In the manufacturing of agricultural implements, such as plows, cultivators, harrows, and rakes, steel flat bars can be utilized for different purposes. They can be used as structural components, providing a strong framework to support the implement's weight and withstand the stresses and strains encountered during operation. Steel flat bars can also be used to create cutting edges or tines, which are essential for effective soil penetration and cultivation. These bars can be shaped, heat-treated, and sharpened to provide a sharp cutting edge that can efficiently break up soil, remove weeds, or level the ground. Furthermore, steel flat bars can be welded or bolted together to assemble various parts of agricultural implements. Their malleability and ease of fabrication make them adaptable for different design requirements. They can be bent, drilled, punched, or machined to achieve the desired shape and functionality. Additionally, steel flat bars have excellent corrosion resistance properties when properly coated or painted. This is crucial for agricultural implements as they are exposed to various environmental conditions, including moisture, soil, and chemicals. Overall, steel flat bars are a reliable and cost-effective choice for the manufacturing of agricultural implements. They offer strength, durability, versatility, and corrosion resistance, making them well-suited for the demanding and challenging conditions encountered in agricultural applications.

- Q: Are steel flat bars available in different colors or finishes?

- Different colors or finishes are typically not available for steel flat bars. The main purpose of steel is its strength and durability, rather than its aesthetic appeal. Nevertheless, there are cases where steel flat bars can be painted or powder coated in various colors for decorative reasons. Moreover, steel can be treated or coated with different finishes, like galvanized or stainless steel, to enhance its resistance to corrosion.

- Q: How do steel flat bars perform in terms of chemical resistance?

- Steel flat bars generally have good chemical resistance, especially when compared to other materials like wood or plastic. However, the exact level of resistance can vary depending on the specific type of steel and the chemical it is exposed to. In general, steel is resistant to many common chemicals such as water, mild acids, and alkalis. However, it may corrode or react with certain aggressive chemicals or environments, such as strong acids, bases, or saltwater. Therefore, it is important to consider the specific chemical environment and consult relevant material compatibility charts or experts to ensure the appropriate level of chemical resistance for a particular application.

- Q: What is the difference between a steel flat bar and a steel square tube?

- Steel flat bars and steel square tubes are two types of steel materials commonly utilized in construction and manufacturing. However, they vary in terms of shape and structural characteristics. The primary distinction lies in their cross-sectional shape. A steel flat bar boasts a rectangular form with two flat parallel surfaces and straight edges, whereas a steel square tube exhibits a hollow square shape with four equal sides and thicker walls. Concerning structural properties, a steel flat bar is typically employed for its strength in resisting bending or flexing. It frequently serves as a support or reinforcement in construction projects, such as framing or bracing. Conversely, a steel square tube provides superior strength and rigidity due to its hollow structure. It is frequently utilized as a structural element for load-bearing applications, such as building frameworks, machinery, or furniture manufacturing. Moreover, the manufacturing process for these two steel forms can differ. Steel flat bars are usually produced through hot rolling, which entails heating the steel billet and passing it through a series of rolling stands. This procedure yields a flat shape with smooth surfaces. Conversely, steel square tubes are generally manufactured through electric resistance welding (ERW), wherein a flat steel strip is transformed into a tube shape and subsequently welded along the edges. In conclusion, although both steel flat bars and steel square tubes are composed of the same material, their shape and structural properties render them suitable for distinct applications. Steel flat bars are commonly utilized for support and reinforcement purposes, while steel square tubes are preferred for load-bearing applications due to their enhanced strength and rigidity.

- Q: Can steel flat bars be used in marine applications?

- Indeed, steel flat bars have the potential to serve marine purposes. Nevertheless, it is crucial to utilize a particular variant of steel referred to as marine-grade or stainless steel for such endeavors. Conventional steel is vulnerable to corrosion and rust in the presence of saltwater or environments with elevated humidity, both of which are prevalent in marine settings. Conversely, marine-grade steel is purposefully crafted to endure the demanding circumstances of the marine milieu. It displays remarkable resistance to corrosion, rust, and pitting, rendering it ideal for incorporation in marine undertakings, including boat fabrication, ship assembly, and offshore platform construction.

Send your message to us

Good Quality Flat Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords