Standard Size Steel Channel Bar, Metal Channel Bar

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Standard Size Steel Channel Bar, Metal Channel Bar

1.Our company enjoys high reputation on manufacturing and supplying U channel steel. Among those steel products, the U channel steel as per japanese, chinese and european can be regarded as our primary products.

Under those standard, the material grade includes: GB Q235B,GB Q345B/JIS G3192, SS400/EN 10025,S235JR and so on.

Here,the U channel steel as per japanese standard is posted just as reference.

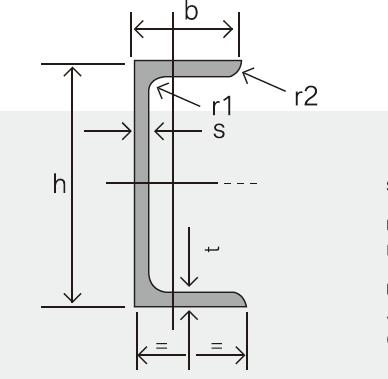

2. Dimension Figure:

Note:1.The height ranges from 50mm to 300mm

2.The breadth ranges from 25mm to 89mm

3.Theoretically speaking, the flange of U channel steel should bear stress, it’s to say that the U channel should be upright rather than lying under construction. Therefore, we strictly control the tolerance of the flange thickness.

3.The sections of U Channel Steel as per JIS Standard are shown in the below table:

JIS U CHANNEL | Standard h | Sectional b | Dimension s | t | Mass: Kg/m |

| (mm) | (mm) | (mm) | (mm) |

|

50x25 | 50 | 25 | 3.0 | 6.00 | 2.37 |

75X40 | 75 | 40 | 3.8 | 7.00 | 5.30 |

75X40 | 75 | 40 | 4.0 | 7.00 | 5.60 |

75X40 | 75 | 40 | 4.5 | 7.00 | 5.85 |

75X40 | 75 | 40 | 5.0 | 7.00 | 6.92 |

|

|

|

|

|

|

100X50 | 100 | 50 | 3.8 | 6.00 | 7.30 |

100X50 | 100 | 50 | 4.2 | 6.00 | 8.03 |

100X50 | 100 | 50 | 4.5 | 7.50 | 8.97 |

100X50 | 100 | 50 | 5.0 | 7.50 | 9.36 |

|

|

|

|

|

|

125X65 | 125 | 65 | 5.2 | 6.80 | 11.66 |

125X65 | 125 | 65 | 5.3 | 6.80 | 12.17 |

125X65 | 125 | 65 | 5.5 | 8.00 | 12.91 |

125X65 | 125 | 65 | 6.0 | 8.00 | 13.40 |

|

|

|

|

|

|

150x75 | 150 | 75 | 5.5 | 7.30 | 14.66 |

150x75 | 150 | 75 | 5.7 | 10.00 | 16.71 |

150x75 | 150 | 75 | 6.0 | 10.00 | 17.90 |

150x75 | 150 | 75 | 6.5 | 10.00 | 18.60 |

150x75 | 150 | 75 | 6.5 | 10.00 | 24.00 |

|

|

|

|

|

|

200X80 | 200 | 80 | 7.5 | 11.00 | 24.60 |

5.Mechanical Property of U Channel Steel as per JIS Standard:

Grade | Yield Strength,N/mm² | Extension Strength N/mm² | |||

Thickness of Steel,mm | |||||

≦16 | >16-≦40 | >40-≦100 | >100 | ||

SS330 | ≧205 | ≧195 | ≧175 | ≧165 | 330-430 |

SS400 | ≧245 | ≧235 | ≧215 | ≧205 | 400-510 |

SS490 | ≧285 | ≧275 | ≧255 | ≧245 | 490-610 |

SS540 | ≧400 | ≧390 | - | - | ≧540 |

6. Chemical Composition of U Channel Steel as per JIS Standard:

Grade | Element(%) | |||

C | Mn | P | S | |

SS330 | -- | -- | ≦0.050 | ≦0.050 |

SS400 | ||||

SS490 | ||||

SS540 | ≦0.30 | ≦1.60 | ≦0.040 | ≦0.040 |

Note: we are also competent to supply structure steel u channel as per other sections, which depends on the customer's requirements for the quantity.

Applications of Standard Size Steel Channel Bar, Metal Channel Bar

U channel steel could be regarded as carbon steel or plain steel. Typically, it is stiff and strong. Carbon steels do rust easily, but they can be easily painted or primed. They are cheap so they are the normal choice for most fabrications. U channel steel is often used as supporting members, most commonly in the house raising industry to strengthen timber bears under houses. Transmission line towers.

And our products are widely used in Architectural Constructions,Telecom tower,Sub Station Structure,Microwave tower Factory and warehousing shed,Electrification projects, poles and earthing E.O.T. cranes,Material handling equipments,Ship building,Automobile

Package & Delivery of Standard Size Steel Channel Bar, Metal Channel Bar

The u channel steel will be packed in bundle with steel wire at each end of every bundle and color marking in order to help the customer to recognize his goods more easily at sight.

And u channel steel could be loaded into 20ft or 40ft container, or by bulk cargo. If the weight of each bundle reaches less than 3.5 mt, the loading by break bulk cargo should be choosed. When the weight of each bundle reaches less than 3mt, the loading by container should be choosed.

As for the transportaion from mill to loading port, the truck will be usually used. And the maximum quantity for each truck is 40mt.

In a word, we do try our best to satisfy all the customer's requirements.

Production Flow of Standard Size Steel Channel Bar, Metal Channel Bar

1.The steel billet shall be heated in the high temperature furnace.

2. The heated steel billet shall be rolled five to nine times with the aim of shaping the general figure of steel u channel.

3. The rolled steel u channel should be put onto the cooling bed to make the temperature low.

4. The steel u channel should be straighted on the straightener.

5. The straighted steel u channel will be cut into meters by saw, as per customer's requirements.

- Q: Can steel angles be used for acoustic isolation or noise barriers?

- Steel angles can be used for acoustic isolation or noise barriers, although they may not be as effective as other materials specifically designed for this purpose. Steel angles can help to reduce noise transmission to some extent by reflecting and absorbing sound waves. However, their effectiveness depends on various factors such as the thickness and density of the steel, as well as the overall design and construction of the barrier. Additionally, steel angles are not typically designed to have soundproofing properties, so using them alone may not provide optimal acoustic isolation. It is recommended to consider specialized materials and techniques specifically designed for noise barriers to achieve the best results.

- Q: How do steel angles contribute to the overall torsional stiffness of a structure?

- Steel angles can contribute to the overall torsional stiffness of a structure in several ways. Firstly, steel angles have a high moment of inertia, which means they are resistant to bending. This resistance to bending helps to distribute and resist the torsional forces acting on the structure, reducing any twisting or warping that may occur. Secondly, steel angles can be strategically placed and connected in a structure to form bracing or reinforcement systems. These systems help to transfer and distribute torsional forces throughout the structure, preventing localized areas from experiencing excessive twisting or distortion. Furthermore, steel angles can be used to create rigid connections between different structural members, such as beams or columns. These connections enhance the overall stiffness of the structure by effectively transmitting torsional forces between the connected members, minimizing any relative movement or deformation. Moreover, steel angles can also be utilized as diagonal members in truss structures or frames. By introducing diagonals, the angles help to resist and distribute torsional forces, maintaining the overall stability and rigidity of the structure. Overall, steel angles play a crucial role in enhancing the torsional stiffness of a structure by providing resistance to bending, forming bracing or reinforcement systems, creating rigid connections, and acting as diagonal members. By effectively managing and distributing torsional forces, steel angles contribute to the overall stability, durability, and performance of the structure.

- Q: What does "L125*8" stand for in steel structures?

- Angle steel is divided into equal angle steel and unequal angle steel. The expression of the equal angle steel model is b*d, in which B is the unilateral width of the equilateral angle steel, and the D is the thickness, and the unit is MM. Unequal angles are named by the ratio of the length to the width of a centimeter and the width of a short edge. Therefore, the L125*8 represents an equilateral angle steel beam with a unilateral width of 125 and a thickness of 8. I hope this problem can be solved for you.

- Q: Can steel angles be used for mezzanines or catwalks?

- Yes, steel angles can be used for mezzanines or catwalks. Steel angles are often used as structural supports in construction projects due to their strength and versatility. They can provide the necessary stability and load-bearing capacity required for mezzanines and catwalks, making them a suitable choice for such applications.

- Q: What are the environmental benefits of using steel angles?

- There are several environmental benefits of using steel angles in construction and various industries. Firstly, steel is a highly recyclable material. The production of steel angles involves recycling scrap steel, which reduces the need for extracting and processing new raw materials. This recycling process helps conserve natural resources and reduces the energy and water consumption associated with mining and refining metals. Additionally, steel is known for its durability and longevity. Steel angles have a long lifespan and require minimal maintenance, reducing the need for frequent replacements. This durability helps to minimize waste and the associated environmental impact of manufacturing and disposing of new materials. Moreover, steel is a non-combustible material, making it a safer option for construction. Unlike certain other materials, steel angles do not contribute to the spread of fires, reducing the risk of environmental damage and potential harm to human health. Furthermore, steel is highly energy-efficient. Steel angles can be manufactured using energy-efficient processes, and steel structures are known for their thermal efficiency. This means that steel buildings require less energy for heating and cooling, reducing overall energy consumption and greenhouse gas emissions. Lastly, the use of steel angles can contribute to sustainable building practices. Steel structures can be designed to maximize natural light and ventilation, reducing the need for artificial lighting and air conditioning. Additionally, steel can be easily repurposed or recycled at the end of its lifespan, further reducing waste and environmental impact. In conclusion, the environmental benefits of using steel angles include their recyclability, durability, non-combustibility, energy efficiency, and contribution to sustainable building practices. By choosing steel angles for construction and industrial applications, we can minimize resource consumption, waste generation, and greenhouse gas emissions, promoting a more sustainable and environmentally-friendly future.

- Q: Can steel angles be used in the construction of museums?

- Yes, steel angles can be used in the construction of museums. Steel angles are commonly used as structural components in construction projects, including museums. They provide strength, stability, and versatility, making them suitable for various architectural and design requirements in museum construction.

- Q: What is the purpose of using steel angles in construction?

- Steel angles are commonly used in construction for several purposes. The primary purpose of using steel angles is to provide structural support and stability to various components of a building or structure. These angles are often used to reinforce corners, edges, and joints, adding strength and rigidity to the overall structure. Additionally, steel angles are used to distribute and transfer loads or forces within the construction. They help to evenly distribute the weight and stress across different parts of the structure, preventing any concentrated points of weakness. Moreover, steel angles are versatile and can be easily customized and fabricated to meet specific construction requirements. They can be cut, drilled, and welded, allowing for seamless integration into a wide range of construction projects. Furthermore, steel angles offer excellent durability and resistance to corrosion, making them suitable for both indoor and outdoor applications. They can withstand heavy loads, extreme weather conditions, and provide long-lasting support to the structure. In summary, the purpose of using steel angles in construction is to enhance the structural integrity, provide support and stability, distribute loads, and ensure the longevity of the building or structure.

- Q: Can steel angles be used in the construction of solar panel support structures?

- Indeed, the utilization of steel angles is viable for the establishment of support structures for solar panels. The construction sector frequently utilizes steel angles owing to their robustness and endurance. They offer exceptional support and stability, which are vital aspects for solar panel installations. The fusion or fastening of steel angles can be effortlessly accomplished to form sturdy and inflexible structures capable of enduring the weight of solar panels and the diverse environmental conditions, including wind and snow loads, to which they may be exposed. Furthermore, steel angles can be tailored to meet the precise design prerequisites of the support structure for solar panels, rendering them a versatile option for construction ventures.

- Q: What are the different types of connections used for steel angles in marine applications?

- Steel angles are commonly utilized in marine applications to provide structural support and reinforcement. To ensure their stability and strength in the harsh marine environment, various types of connections are employed. The different connection methods for steel angles in marine applications include: 1. Welded Connections: Welding is widely used to connect steel angles in marine applications. This method involves melting the base metals and allowing them to cool and solidify, resulting in strong and durable connections. Welded connections are ideal for heavy-duty marine applications due to their excellent strength and durability. 2. Bolted Connections: Another commonly used method is bolted connections, which involve securing the angles together using bolts, nuts, and washers. Bolted connections offer easy installation and allow for disassembly if needed. They are suitable when adjustments or replacements of the angles are required. 3. Riveted Connections: Riveting, an older connection method, is still employed in certain marine applications. It entails using rivets, metal pins with heads, to connect the angles. The rivets are inserted through pre-drilled holes in the angles and deformed to secure them. Riveted connections offer good strength and vibration resistance, but they can be time-consuming to install compared to other methods. 4. Adhesive Connections: Adhesive bonding is a contemporary method used to connect steel angles in marine applications. This method involves utilizing high-strength adhesives to join the angles together. Adhesive connections evenly distribute stress across the connected surfaces and eliminate the need for drilling or welding. However, they require meticulous surface preparation and curing time for optimal strength. 5. Hybrid Connections: In certain cases, a combination of different connection methods may be employed for steel angles in marine applications. For instance, a welded-bolted connection may be used to enhance strength and redundancy. Hybrid connections offer the advantages of multiple connection methods while ensuring a robust and reliable connection. The choice of connection type for steel angles in marine applications depends on factors such as load requirements, environmental conditions, and project specifications. It is crucial to consider the specific needs of the application and consult with structural engineers and marine professionals to determine the most suitable connection method.

- Q: What is the process of cold bending steel angles?

- The process of cold bending steel angles involves using hydraulic or mechanical forces to gradually shape the steel angle into a desired curve or angle without the use of heat. This is achieved by carefully manipulating and applying pressure to the steel angle until it is bent to the desired shape.

Send your message to us

Standard Size Steel Channel Bar, Metal Channel Bar

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords