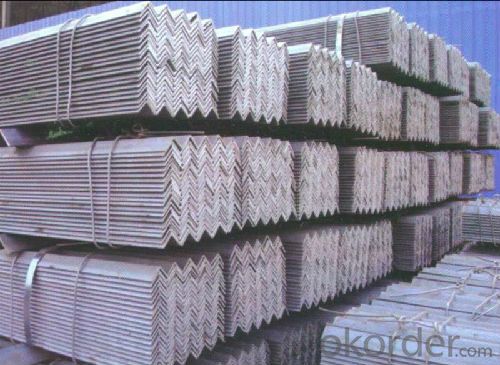

HOT ROLLED STEEL EQUAL ANGLE for construction JIS G3192

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering hot rolled steel equal angle for construction JIS G3192at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Hot rolled steel equal angle are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's steel equal angle are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricin

Product Specifications:

1. Invoicing on theoretical weight or actual weight as customer request

2. Length: 6m, 9m, 12m as following table

3. Sizes

:

5. Payment terms:

1).100% irrevocable L/C at sight.

2).30% T/T prepaid and the balance against the copy of B/L.

3).30% T/T prepaid and the balance against L/C

FAQ:

Q1: How do we guarantee the quality of our products?A1: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q2: How soon can we receive the product after purchase

A2: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Images:

- Q: How do you design connections for steel angles?

- When designing connections for steel angles, several factors need to be considered to ensure structural integrity and safety. Here are the key steps in designing connections for steel angles: 1. Determine the load and forces: Understand the loads the connection will be subjected to, such as tension, compression, or shear forces. Calculate the magnitude and direction of these forces to accurately assess the connection's requirements. 2. Select the type of connection: Determine the appropriate connection type based on the forces involved, structural design, and aesthetic requirements. Common connection types for steel angles include bolted, welded, or a combination of both. 3. Size the angles: Determine the appropriate size of the steel angles based on the loads and forces. Consider the angle's cross-sectional shape, material strength, and desired safety factors to ensure it can withstand the applied loads. 4. Check for interaction effects: Assess any interaction effects between the connection and the structural members. Account for any changes in the behavior of the angles due to the connection, such as added stiffness or reduction in capacity. 5. Design the connection details: Once the connection type and angle size are determined, design the connection details. Consider factors like the number and size of bolts, welding specifications, edge distances, and spacing requirements. 6. Check for failure modes: Analyze the connection design for potential failure modes, such as bearing, tearing, or shearing. Ensure that the connection has adequate strength and ductility to resist these failure modes. 7. Perform calculations and analysis: Utilize appropriate engineering principles and standards to perform calculations and analysis on the connection design. Check for factors like static equilibrium, stress distribution, and load transfer to confirm the connection's adequacy. 8. Incorporate design codes and standards: Adhere to relevant design codes and standards, such as the American Institute of Steel Construction (AISC) Manual, to ensure compliance with industry best practices and safety requirements. 9. Consider constructability and ease of fabrication: While designing connections, consider the constructability and ease of fabrication. Aim for simplicity in connection details to facilitate efficient manufacturing and construction processes. 10. Review and revise: Finally, review the connection design and seek input from structural engineers or other experts. Revise the design as necessary based on their recommendations to optimize the connection's performance and efficiency. By following these steps, engineers can design connections for steel angles that effectively transfer forces, ensure structural stability, and meet safety requirements.

- Q: How do you prevent buckling of steel angles under compressive loads?

- To prevent steel angles from buckling under compressive loads, there are several steps that can be taken: 1. Increasing the section modulus: By broadening or thickening the steel angle, its ability to resist bending can be improved, thus enhancing its resistance to compressive loads without buckling. 2. Increasing the moment of inertia: The moment of inertia, which determines a cross-sectional shape's resistance to bending, can be increased by either adding more material or using a different shape with a greater moment of inertia. This makes the steel angle stiffer and less prone to buckling. 3. Providing lateral support: Lateral support can be provided by incorporating bracing or stiffeners into the steel angle. This helps distribute the compressive load and prevents buckling. The bracing or stiffeners should be designed to withstand the applied loads and prevent any local distortions or deformations. 4. Using thicker or higher strength steel: Thicker steel has a higher resistance to bending, while higher strength steel can bear greater stresses before reaching its yield point. By utilizing thicker or higher strength steel, the steel angle can withstand higher compressive loads without buckling. 5. Properly designing and installing connections: The connections between the steel angle and other structural components should be carefully designed and installed. Sufficient connection details should be provided to ensure proper transfer of the compressive load and adequate support for the steel angle. 6. Taking the effective length factor into consideration: The effective length factor is a parameter that considers the buckling behavior of a member. By accurately incorporating the effective length factor into design calculations, the risk of buckling can be minimized. 7. Conducting a comprehensive structural analysis: It is crucial to conduct a structural analysis to determine the expected compressive loads and potential buckling modes. By utilizing appropriate software or calculations, the necessary measures can be implemented to prevent buckling. In conclusion, preventing buckling of steel angles under compressive loads requires a combination of design considerations, material selection, and proper installation techniques. By following these measures, the structural integrity and safety of steel angles can be ensured in various applications.

- Q: Are steel angles fire resistant?

- Steel angles are commonly regarded as fire resistant. This is because steel is a material that does not burn and can withstand high temperatures. Steel angles, which are L-shaped structural components, are widely used in construction and engineering due to their strength and durability. In the event of a fire, steel angles remain structurally intact and do not deform, which is crucial for the safety of a building or structure. However, it is important to consider that the fire resistance of steel angles may be influenced by various factors such as size, thickness, fire protection measures, and the duration and intensity of the fire. To enhance the fire resistance of steel angles and improve overall fire safety, measures like fire-resistant coatings, fire barriers, and fireproofing materials can be employed.

- Q: Can steel angles be used for framing in modular construction?

- Yes, steel angles can be used for framing in modular construction. Steel angles are commonly used for their structural strength and versatility, making them suitable for various framing applications in modular construction projects.

- Q: How are steel angles installed?

- Installing steel angles is a straightforward process that involves a few basic steps. To begin, mark the desired location for the angle on the surface or structure where it will be installed. Use a level and measuring tape to ensure proper alignment and mark the positions for the screw or bolt holes. Once the markings are complete, it is necessary to pre-drill the holes using a drill bit slightly smaller than the screws or bolts you will use. This prevents the steel angle from cracking or splitting during installation. After pre-drilling, place the steel angle back in position and align the holes with the markings on the surface. Use a wrench or screwdriver to securely tighten the screws or bolts, ensuring the angle is firmly attached. To ensure a successful installation, it is essential to follow the manufacturer's instructions and recommendations for the specific type and size of steel angle. Additionally, verify that the surface or structure can support the weight and load it will bear. In summary, steel angles are easy to install and offer excellent structural support in a variety of applications, including construction, manufacturing, and DIY projects.

- Q: Can steel angles be used in high-rise buildings?

- Yes, steel angles can be used in high-rise buildings. Steel angles are commonly used as structural members in high-rise buildings due to their strength, versatility, and cost-effectiveness. They can be used in various applications such as framing, bracing, and supporting loads. Steel angles provide stability and structural integrity to the building, allowing it to withstand the forces and stresses associated with high-rise structures. Additionally, steel angles can be easily fabricated, manipulated, and connected, making them suitable for the complex and intricate designs often found in high-rise buildings. Overall, steel angles are a reliable and commonly used component in the construction of high-rise buildings.

- Q: Are there any limitations or restrictions on the use of steel angles in certain applications?

- Yes, there are limitations and restrictions on the use of steel angles in certain applications. These restrictions mainly depend on the specific engineering requirements, load bearing capacity, and structural stability needed for the application. Additionally, factors such as the type of project, environmental conditions, and building codes and regulations may also impose limitations on the use of steel angles. It is important to consult with a structural engineer or an industry professional to ensure proper selection and usage of steel angles for specific applications.

- Q: Can steel angles be used for manufacturing machinery?

- Indeed, the utilization of steel angles is viable for the production of machinery. In the construction sector, steel angles are frequently employed as structural elements owing to their robustness, resilience, and cost-effectiveness. In the realm of machinery manufacturing, steel angles find utility in a multitude of ways, encompassing framing, support structures, brackets, and mounting components. They bestow stability and rigidity upon the machinery, thereby ensuring its structural integrity. Moreover, steel angles facilitate the welding, bolting, or riveting processes with ease, permitting flexible and efficient fabrication techniques. By and large, steel angles represent a versatile and dependable choice for the manufacturing of machinery.

- Q: What is the maximum length for a curved steel angle?

- Several factors, such as the diameter of the curve, the steel thickness, and the project's specific requirements, determine the maximum length of a curved steel angle. Typically, the length can range from a few inches to several feet. However, it is crucial to seek guidance from a structural engineer or manufacturer to ensure the angle's structural integrity is not compromised. The manufacturing process and available equipment may also influence the achievable maximum length for a curved steel angle.

- Q: Can steel angles be used in industrial or heavy-duty applications?

- Absolutely, steel angles are a perfect fit for industrial or heavy-duty uses. Renowned for their robustness, endurance, and flexibility, steel angles are highly versatile and find application across a wide range of industries. They play a vital role in providing structural reinforcement, support, and stability to heavy-duty machinery, equipment, and infrastructure projects. Construction, manufacturing, engineering, transportation, and various other industries commonly employ steel angles. Their usage spans frames, supports, bracings, platforms, beams, and trusses, where strength and load-bearing capacity are paramount. Moreover, steel angles can withstand extreme temperatures, harsh weather conditions, and heavy loads, making them ideal for demanding industrial environments. In summary, steel angles are a dependable and efficient choice for industrial or heavy-duty applications, thanks to their strength, durability, and adaptability.

Send your message to us

HOT ROLLED STEEL EQUAL ANGLE for construction JIS G3192

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches