JISG3192 galvanized angle steel for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

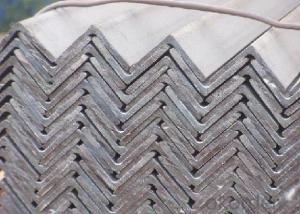

Specifications of Equal Angle Steel

1.Standards:GB,ASTM,BS,AISI,DIN,JIS

2.Length:6m,9m,12m

3.Material:GBQ235B,Q345BorEquivalent;ASTMA36;EN10025,S235JR,S355JR;JISG3192,SS400;SS540.

.

4.Sizes:

EQUAL ANGLES SIZES |

| ||

a(mm) | a1(mm) | thickness(mm) | length |

25 | 25 | 2.5---3.0 | 6M/12M |

30 | 30 | 2.5---4.0 | 6M/12M |

38 | 38 | 2.5 | 6M/12M |

38 | 38 | 3.0---5.0 | 6M/12M |

40 | 40 | 3.0---6.0 | 6M/12M |

50 | 50 | 3 | 6M/12M |

50 | 50 | 3.7---6.0 | 6M/9M/12M |

60 | 60 | 5.0---6.0 | 6M/9M/12M |

63 | 63 | 6.0---8.0 | 6M/9M/12M |

65 | 65 | 5.0---8.0 | 6M/9M/12M |

70 | 70 | 6.0---7.0 | 6M/9M/12M |

75 | 75 | 5.0---10.0 | 6M/9M/12M |

80 | 80 | 6.0---10.0 | 6M/9M/12M |

90 | 90 | 6.0---10.0 | 6M/9M/12M |

100 | 100 | 6.0---12.0 | 6M/9M/12M |

120 | 120 | 8.0-12.0 | 6M/9M/12M |

125 | 125 | 8.0---12.0 | 6M/9M/12M |

130 | 130 | 9.0-12.0 | 6M/9M/12M |

140 | 140 | 10.0-16.0 | 6M/9M/12M |

150 | 150 | 10---15 | 6M/9M/12M |

160 | 160 | 10---16 | 6M/9M/12M |

180 | 180 | 12---18 | 6M/9M/12M |

200 | 200 | 14---20 | 6M/9M/12M |

5. Material details:

Alloy No | Grade | Element (%) | |||||

C | Mn | S | P | Si | |||

|

|

|

|

|

|

| |

Q235 | B | 0.12—0.20 | 0.3—0.7 | ≤0.045 | ≤0.045 | ≤0.3 | |

|

|

|

|

|

|

| |

Alloy No | Grade | Yielding strength point( Mpa) | |||||

Thickness (mm) | |||||||

≤16 | >16--40 | >40--60 | >60--100 | ||||

≥ | |||||||

|

|

|

|

|

| ||

Q235 | B | 235 | 225 | 215 | 205 | ||

Alloy No | Grade | Tensile strength (Mpa) | Elongation after fracture (%) | ||||

Thickness (mm) | |||||||

| ≤16 | >16--40 | >40--60 | >60--100 | |||

≥ | |||||||

|

|

|

|

|

|

| |

Q235 | B | 375--500 | 26 | 25 | 24 | 23 | |

Usage & Applications of Equal Anlge Steel

Trusses;

Transmission towers;

Telecommunication towers;

Bracing for general structures;

Stiffeners in structural use.

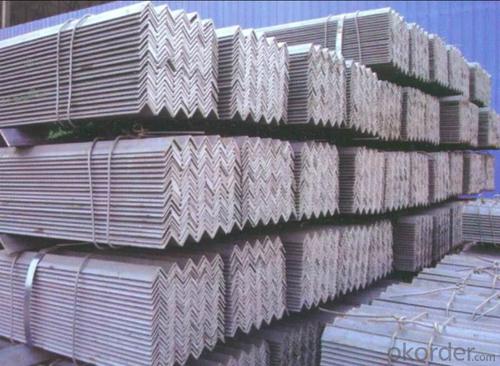

Packaging & Delivery of Equal Angle Steel

1. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

2. With bundles and load in 20 feet/40 feet container, or by bulk cargo, also we could do as customer's request.

3. Marks:

Color mark: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: There will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

- Q: Can steel angles be used as reinforcements in concrete structures?

- Yes, steel angles can be used as reinforcements in concrete structures. Steel angles are commonly used as reinforcement in concrete structures due to their high strength and durability. They are typically placed within the concrete to provide additional support and prevent cracking or failure under heavy loads or stress. Steel angles are versatile and can be easily incorporated into the design of various concrete structures such as beams, columns, walls, and slabs. They are often used in combination with other types of reinforcement like steel bars or mesh to enhance the overall strength and stability of the concrete structure. Steel angles are preferred for their ease of installation, cost-effectiveness, and ability to withstand the harsh environmental conditions typically encountered in construction projects.

- Q: Can steel angles be painted or finished for decorative purposes?

- Indeed, steel angles have the potential to be painted or finished in order to achieve decorative purposes. These steel angles, commonly utilized in construction and industrial settings, can undergo painting or finishing procedures to enhance their visual appeal and contribute a decorative element. The act of painting steel angles serves the dual purpose of safeguarding them against corrosion and rust, while also allowing for customization to align with the aesthetic requirements of the particular project. Furthermore, alternative finishes such as powder coating, electroplating, or galvanizing can be employed to augment both the appearance and durability of these steel angles. Through the application of paint or finishing techniques, steel angles can be seamlessly integrated into a variety of architectural and design ventures, thereby serving both functional and visually enticing purposes.

- Q: How are steel angles protected against UV degradation?

- Various methods can be employed to protect steel angles from UV degradation. Applying a protective coating or paint onto the surface of the steel angles is a common approach. These coatings typically contain UV inhibitors that shield against the harmful effects of ultraviolet rays. By absorbing or reflecting the UV radiation, the inhibitors reduce the potential for degradation. Another method is to galvanize the steel angles by coating them with a layer of zinc. This not only provides corrosion resistance but also offers some protection against UV radiation. Zinc possesses natural UV-blocking properties, which aid in minimizing the effects of UV degradation. In addition to coatings and galvanization, utilizing weather-resistant materials during the manufacturing process is another technique. These materials are specifically designed to withstand UV exposure and effectively safeguard the steel from degradation over time. Regular maintenance and inspections are essential to ensure ongoing protection against UV degradation. This includes cleaning the steel angles to remove dirt and debris that may trap moisture and hasten degradation. Periodic reapplication of coatings or touch-ups should also be performed to ensure long-term protection against UV radiation. In conclusion, a combination of protective coatings, galvanization, the use of weather-resistant materials, and proper maintenance can effectively protect steel angles from UV degradation.

- Q: Can steel angles be used for manufacturing bike racks?

- Yes, steel angles can be used for manufacturing bike racks. Steel angles provide strength and stability required to support the weight of bicycles and withstand outdoor conditions.

- Q: Can steel angles be used for shelving?

- Yes, steel angles can be used for shelving. Steel angles are commonly used in shelving systems as they provide strength, stability, and durability. They can be easily mounted on walls or used as supports for shelves, making them ideal for various storage applications.

- Q: What is the maximum deflection allowed for steel angles?

- There are various factors that determine the maximum deflection allowed for steel angles, such as the specific grade of steel, the angle's length, and the applied load. In the field of structural engineering, deflection limits are established in order to ensure the safety and performance of structures. Typically, the deflection limit for steel angles is expressed as a fraction of the span length, denoted as L/240 or L/360, where L represents the unsupported length of the angle. For instance, if the unsupported length of a steel angle measures 240 inches, the allowable maximum deflection would be either 1 inch (240/240) or 0.67 inches (240/360). Nevertheless, it is crucial to acknowledge that these deflection limits may vary depending on the specific design codes and standards employed in a given project. For more precise and specific information regarding the maximum deflection permitted for steel angles in a particular application, it is advisable to consult the relevant code or seek guidance from a structural engineer.

- Q: Can steel angles be used in machine frames?

- Machine frames can indeed utilize steel angles. Thanks to their robustness and longevity, steel angles are frequently employed in construction and engineering ventures. By offering structural reinforcement and stability, they guarantee the steadfastness and resilience of machine frames, even when faced with heavy loads and vibrations. Welding or bolting steel angles together enables the creation of unyielding and steady frames, rendering them a superb option for machine frames that demand exceptional strength and stability. Moreover, steel angles are readily obtainable in diverse sizes and thicknesses, granting the freedom to tailor and personalize machine frames to meet precise specifications.

- Q: Can steel angles be used in agricultural applications?

- Yes, steel angles can be used in agricultural applications. They are commonly used in the construction of buildings, fences, and equipment in the agricultural industry due to their strength, durability, and versatility.

- Q: Can steel angles be used for architectural detailing or ornamentation?

- Yes, steel angles can be used for architectural detailing or ornamentation. They are commonly used to add structural support, create unique design elements, and enhance the aesthetic appeal of buildings. Their versatility, strength, and durability make them suitable for various architectural applications.

- Q: Are steel angles resistant to earthquakes?

- Steel angles can provide some level of resistance to earthquakes. Steel is known for its high strength and ductility, making it a suitable material for seismic-resistant construction. Steel angles, also known as steel L-shaped beams, are often used in structural applications to provide support and reinforcement. During an earthquake, steel angles can help distribute the seismic forces evenly throughout the structure, thereby reducing concentrated stress points. The L-shape design of steel angles enables them to resist bending and twisting forces, which are common during seismic events. Additionally, steel angles can be interconnected and welded together to form a rigid frame system, enhancing their seismic resistance. This system can absorb and dissipate energy from earthquake-induced vibrations, minimizing damage to the structure. However, it is important to note that the overall seismic resistance of a structure depends on various factors, such as the design, construction methods, and adherence to building codes and regulations. Steel angles alone cannot guarantee complete protection against earthquakes, but when properly integrated into a well-designed seismic-resistant system, they can significantly enhance the structure's ability to withstand seismic forces.

Send your message to us

JISG3192 galvanized angle steel for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords