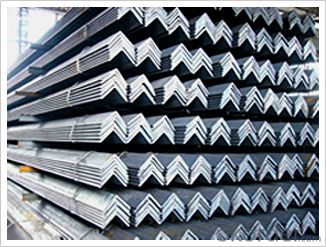

Hot rolled Equal steel angle for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering hot rolled Equal steel angle for construction at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Hot rolled Equal steel angle for construction are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Steel angle are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

1. Invoicing on theoretical weight or actual weight as customer request

2. Length: 6m, 9m, 12m as following table

3. Sizes

1).100% irrevocable L/C at sight.

2).30% T/T prepaid and the balance against the copy of B/L.

3).30% T/T prepaid and the balance against L/C

Usage & Applications of Angle Steel

According to the needs of different structures, Angle can compose to different force support component, and also can be the connections between components. It is widely used in various building structures and engineering structures such as roof beams, bridges, transmission towers, hoisting machinery and transport machinery, ships, industrial furnaces, reaction tower, container frame and warehouse etc.

Packaging & Delivery of Angle Steel

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

Production flow of Angle Steel

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

FAQ:

Q1: How do we guarantee the quality of our products?

A1: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q2: Can stainless steel rust?

A2: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

- Q: Can steel angles be used for handrail supports?

- Indeed, handrail supports can utilize steel angles. In the realm of construction, steel angles are frequently employed to furnish structural support and ensure stability. These L-shaped steel components possess remarkable strength and durability. Once carefully installed and firmly fastened, steel angles can proficiently uphold handrails, furnishing a robust framework for individuals to lean on or grasp whilst ascending stairs or traversing elevated surfaces. The selection of steel angles for handrail supports hinges on considerations such as the desired load capacity, design specifications, and adherence to local building codes.

- Q: What is the typical ductility of steel angles?

- The typical ductility of steel angles can vary depending on the specific grade and composition of the steel. However, in general, steel angles have good ductility due to the inherent properties of steel, which allows them to be easily bent or deformed without breaking.

- Q: How do you calculate the buckling strength of a steel angle?

- Several factors must be taken into account in order to calculate the buckling strength of a steel angle. The buckling strength refers to the angle's ability to withstand buckling or collapse under applied loads. To begin, the geometry of the steel angle must be established. This involves determining the angle's dimensions, including the length of the legs and the thickness of the steel. Additionally, the cross-sectional properties, such as the moment of inertia and section modulus, need to be computed. Following that, the effective length of the angle needs to be determined. The effective length measures the angle's level of restraint against buckling. It depends on factors such as the boundary conditions and connection details. The effective length can differ for various modes of buckling, such as flexural or torsional buckling. Once the effective length is known, the critical buckling load can be calculated using an appropriate buckling equation. Various buckling equations are available, depending on the boundary conditions and mode of buckling. For example, the Euler buckling equation can be used for long, slender angles subjected to axial compression. Other equations, such as the Johnson buckling equation, may be employed for more complex loading scenarios. The critical buckling load can then be converted to an allowable stress using a suitable safety factor. The safety factor accounts for uncertainties in the calculation and ensures that the angle can safely bear the applied load without buckling. Design codes or industry standards typically specify the safety factor. In conclusion, calculating the buckling strength of a steel angle involves determining its geometry and effective length, applying an appropriate buckling equation, and converting the critical load to an allowable stress using a safety factor. It is essential to consult relevant design codes and standards to ensure accurate and safe calculations.

- Q: How do you determine the axial capacity of a steel angle?

- In order to ascertain the axial capacity of a steel angle, one must consider several factors. First and foremost, it is crucial to determine the yield strength of the steel angle. Typically, this information is provided by the manufacturer and can be found in material specifications. The yield strength denotes the maximum stress that the steel angle can endure without experiencing permanent deformation. Following that, the cross-sectional area of the steel angle must be computed. This can be achieved by measuring the angle's dimensions, such as the thickness and the length of its legs. The cross-sectional area is then obtained by multiplying the thickness by the sum of the two leg lengths. Once the cross-sectional area is ascertained, the axial capacity can be calculated by multiplying the yield strength by the cross-sectional area. This will determine the maximum load that the steel angle can bear in a purely axial direction without failure. It is important to bear in mind that there are additional factors that can impact the axial capacity of a steel angle, including the presence of holes or notches, the slenderness ratio, and the loading conditions. Therefore, it is advisable to consult relevant design codes, standards, or engineering handbooks for more comprehensive guidance and to account for these supplementary factors.

- Q: Can steel angles be used for transmission towers?

- Yes, steel angles can be used for transmission towers. Steel angles are commonly used in the construction industry for various structural applications, including transmission towers. They provide excellent strength and stability, making them suitable for supporting heavy loads and withstanding the rigors of outdoor environments. Steel angles can be easily fabricated, welded, and bolted together to form the required shapes and configurations for transmission towers. Additionally, they offer good corrosion resistance, which is crucial for structures exposed to weather conditions. Overall, steel angles are a popular and reliable choice for transmission tower construction.

- Q: Can steel angles be easily modified or customized on-site?

- Yes, steel angles can be easily modified or customized on-site. Steel angles can be cut, drilled, welded, and bent to fit specific requirements. This versatility allows for easy customization and alteration of steel angles to suit various construction or fabrication needs. Additionally, on-site modifications are often necessary to ensure precise fitting and alignment during installation. With the right tools and expertise, steel angles can be modified and customized on-site without significant difficulty.

- Q: What does L50*4 angle mean in CAD?

- Angle called angle, the steel strip is perpendicular to each other on both sides into the corner. There are equal angles and unequal angles. The two sides of an equal angle steel are equal in width. The specifications are expressed in millimeters of edge width * edge width * edge thickness. Such as "30 x 30 x 3", that is 30 mm width equal angle, edge thickness of 3 mm.

- Q: How do you prevent corrosion on steel angles?

- One effective method to prevent corrosion on steel angles is by applying a protective coating such as paint or zinc. This barrier creates a physical barrier between the steel and the corrosive elements in the environment, preventing direct contact and reducing the chances of corrosion. Regular maintenance and inspection, along with promptly addressing any signs of damage or rust, can also help prevent corrosion on steel angles.

- Q: What is the typical length of a steel angle?

- The typical length of a steel angle can vary depending on its purpose and application. However, in most cases, the standard length of a steel angle is typically 20 feet or 6 meters. This length allows for easy handling, transportation, and installation in various construction and fabrication projects. However, it's worth noting that steel angles can be cut or customized to shorter lengths to meet specific requirements or fit certain designs.

- Q: Can steel angles be used as bracing elements in buildings?

- Bracing elements in buildings can indeed consist of steel angles. These angles are frequently utilized in construction due to their impressive strength and versatility. Their primary function is to provide lateral stability and support to structures, making them essential structural components. By utilizing steel angles as bracing elements, buildings become capable of withstanding horizontal forces like wind or seismic activity, thus preventing excessive movement or deformation. These angles are typically placed at strategic points, such as corners or intersections, and can be securely connected to other structural members using bolts or welds. The preference for steel angles as bracing elements is justified by their advantageous features, including a high strength-to-weight ratio, durability, and ease of installation. Therefore, it can be confidently stated that steel angles are a reliable and commonly employed solution for bracing elements in buildings.

Send your message to us

Hot rolled Equal steel angle for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords