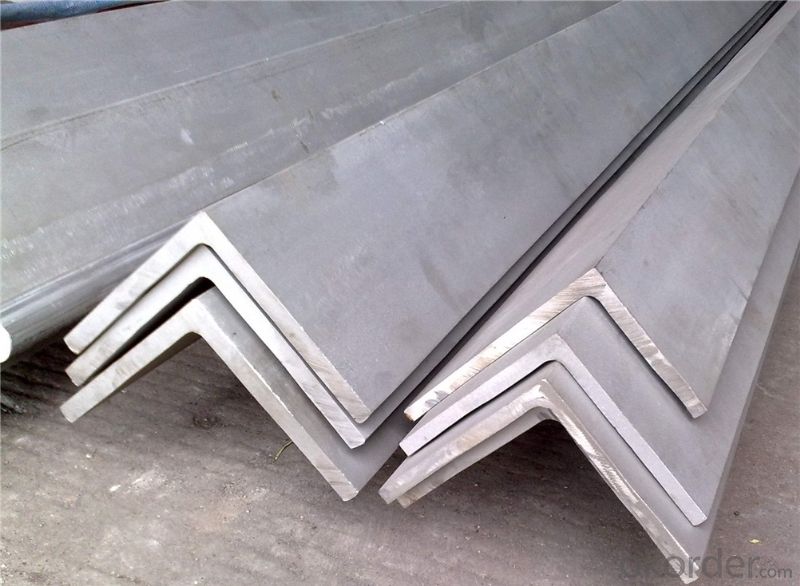

Hot rolled stainless steel angle for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100000 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

OKorder is offering hot rolled stainless steel angle for construction at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Hot rolled stainless steel angle are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Steel angle are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Specifications of Angle Steel

1. Invoicing on theoretical weight or actual weight as customer request

2. Length: 6m, 9m, 12m as following table

1).100% irrevocable L/C at sight.

2).30% T/T prepaid and the balance against the copy of B/L.

3).30% T/T prepaid and the balance against L/C

Packaging & Delivery of Angle Steel

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

Production flow of Angle Steel

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

- Q: Do steel angles require maintenance?

- Maintenance is necessary for steel angles. Despite being durable, steel can still rust and corrode, especially when exposed to moisture or harsh environments. To prevent these problems and prolong the lifespan of steel angles, regular maintenance is required. Common maintenance practices include checking for rust or damage, cleaning the surface to remove dirt and debris, and applying protective coatings or paints to prevent corrosion. Proper storage and handling also play a role in maintaining steel angles. It is crucial to follow manufacturer instructions and seek advice from experts to determine the specific maintenance needs for steel angles in various applications.

- Q: What are the different corrosion protection methods for steel angles?

- There are several different corrosion protection methods available for steel angles, depending on the specific application and environmental conditions. Some of the most common methods include: 1. Galvanization: This involves coating the steel angles with a layer of zinc, which provides excellent corrosion resistance. The zinc layer acts as a sacrificial anode, corroding instead of the underlying steel. 2. Paint coatings: Applying a high-quality paint coating to the steel angles can provide effective corrosion protection. The paint acts as a barrier, preventing moisture and corrosive substances from reaching the steel surface. 3. Powder coating: Similar to paint coatings, powder coating involves applying a dry powder to the steel angles and then baking it to create a durable and corrosion-resistant finish. 4. Epoxy coatings: Epoxy coatings are commonly used for steel angles that will be exposed to harsh environments or aggressive chemicals. These coatings provide excellent adhesion and resistance to corrosion. 5. Cathodic protection: This method involves using a sacrificial anode or impressed current to protect the steel angles from corrosion. The anode corrodes instead of the steel, providing long-term protection. 6. Barrier coatings: Barrier coatings, such as polyethylene or PVC wraps, provide a physical barrier between the steel angles and the surrounding environment, preventing moisture and corrosive substances from reaching the surface. 7. Hot-dip galvanizing: In this method, the steel angles are immersed in a bath of molten zinc, creating a thick layer of zinc coating that offers excellent corrosion protection. It is important to consider the specific requirements of the application when choosing a corrosion protection method for steel angles. Factors such as the environment, expected service life, and budget should be taken into account to ensure the most suitable protection method is selected.

- Q: Can steel angles be used for framing in modular homes?

- Yes, steel angles can be used for framing in modular homes. Steel angles are commonly used in construction for their strength and durability. They are versatile and can be used in various applications, including framing. Steel angles provide excellent load-bearing capacity and structural support, making them suitable for modular home construction. Additionally, steel angles can be easily fabricated and customized to meet specific design requirements. Their resistance to corrosion and fire also adds to their suitability for modular home framing. Overall, steel angles are a reliable and efficient choice for framing in modular homes.

- Q: Are steel angles suitable for constructing bridges?

- Yes, steel angles are suitable for constructing bridges. Steel angles are commonly used in bridge construction due to their strength and versatility. They can be easily fabricated into various shapes and sizes, making them ideal for creating structural members such as beams, columns, and trusses. Steel angles also have high tensile strength, which allows them to withstand heavy loads and forces experienced by bridges. Additionally, steel angles have excellent corrosion resistance properties, ensuring the longevity and durability of the bridge structure. Overall, steel angles are a reliable and cost-effective choice for constructing bridges.

- Q: How do you calculate the load capacity of a steel angle?

- The load capacity of a steel angle can be calculated by determining the maximum axial load that the angle can support before it fails. This can be done by considering various factors such as the dimensions of the angle, the material properties of the steel, and the applied load conditions. Using mathematical equations and formulas, engineers can calculate the load capacity by analyzing the stress and strain distribution within the angle.

- Q: What are the common lengths available for steel angles?

- The common lengths available for steel angles vary depending on the manufacturer and supplier. However, there are standard lengths that are commonly available in the market. These lengths typically range from 10 feet (3.048 meters) to 20 feet (6.096 meters). Some manufacturers may offer longer or shorter lengths based on customer requirements, but the aforementioned lengths are the most commonly found in the industry. It is important to check with the specific manufacturer or supplier for the exact lengths available for steel angles as they may have different options to suit different applications and customer needs.

- Q: What is the typical thickness of the flanges of a steel angle?

- The thickness of the flanges of a steel angle can differ depending on the particular application and industry norms. Typically, flanges of a steel angle are often available in thicknesses ranging from 1/8 inch to 3/4 inch. It is significant to consider that thicker flanges offer greater strength and stability, but also contribute to the weight and cost of the steel angle. To determine the suitable flange thickness, one should consider the specific project requirements and any relevant engineering or design standards.

- Q: Can steel angles be drilled or punched for fastening?

- Yes, steel angles can be drilled or punched for fastening.

- Q: How do you calculate the weight-bearing capacity of a steel angle?

- To calculate the weight-bearing capacity of a steel angle, you need to consider its dimensions, material properties, and loading conditions. The weight-bearing capacity can be calculated using engineering formulas and techniques such as the Euler formula or the AISC Manual. These calculations take into account factors like the cross-sectional area, moment of inertia, and the applied loads to determine the maximum load the steel angle can support without failure.

- Q: How do you calculate the shear strength of a steel angle?

- To calculate the shear strength of a steel angle, you need to determine the area of the cross-section multiplied by the shear stress limit of the material. The shear stress limit can be obtained from the material's specifications or testing.

Send your message to us

Hot rolled stainless steel angle for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100000 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords