S400 Hot rolled stainless steel angle for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100000 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

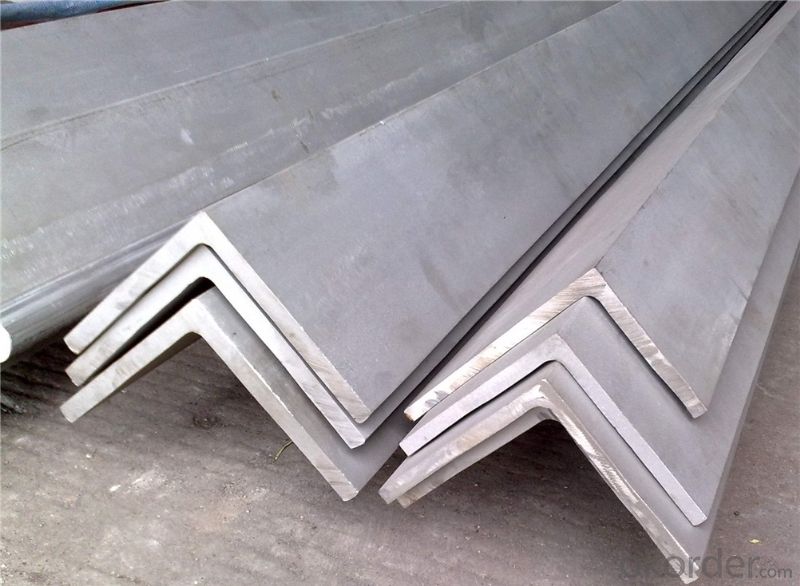

Product Description:

OKorder is offering S400 hot rolled stainless steel angle for construction at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Hot rolled stainless steel angle are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's steel angle are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Specifications of Angle Steel

1. Invoicing on theoretical weight or actual weight as customer request

2. Length: 6m, 9m, 12m as following table

3. Sizes

Sizes: 25mm-250mm | ||

a*t | ||

25*2.5-4.0 | 70*6.0-9.0 | 130*9.0-15 |

30*2.5-6.6 | 75*6.0-9.0 | 140*10-14 |

36*3.0-5.0 | 80*5.0-10 | 150*10-20 |

38*2.3-6.0 | 90*7.0-10 | 160*10-16 |

40*3.0-5.0 | 100*6.0-12 | 175*12-15 |

45*4.0-6.0 | 110*8.0-10 | 180*12-18 |

50*4.0-6.0 | 120*6.0-15 | 200*14-25 |

60*4.0-8.0 | 125*8.0-14 | 250*25 |

5. Payment terms:

1).100% irrevocable L/C at sight.

2).30% T/T prepaid and the balance against the copy of B/L.

3).30% T/T prepaid and the balance against L/C

Packaging & Delivery of Angle Steel

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

Production flow of Angle Steel

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

- Q: Can steel angles be used for reinforcing steel structures?

- Yes, steel angles can be used for reinforcing steel structures. Steel angles are commonly employed to add strength and stability to various steel structures, such as buildings, bridges, and towers. They provide additional support and help distribute loads more efficiently, making them a suitable choice for reinforcing steel structures.

- Q: What are the factors to consider when choosing the appropriate steel angle size?

- When choosing the appropriate steel angle size, there are several factors that need to be considered. Firstly, the load-bearing capacity should be taken into account. It is crucial to determine the maximum weight or load that the steel angle will need to support. This will help in selecting a size that can withstand the required load without any deformation or failure. Secondly, the structural stability and safety should be considered. The steel angle should be able to provide the necessary strength and rigidity to maintain the structural integrity of the application. It is important to ensure that the chosen size can resist any potential structural failures or instabilities that may occur due to external forces or loads. Another factor to consider is the dimensions and shape of the application where the steel angle will be used. The size of the steel angle should be compatible with the available space and design requirements. It is essential to choose a size that can be easily integrated into the overall structure and provide the desired functionality. Additionally, the material properties of the steel angle should be evaluated. Different grades and types of steel have varying mechanical properties, such as yield strength, tensile strength, and corrosion resistance. By considering the specific application requirements and environmental conditions, the appropriate steel grade and size can be selected to ensure durability and longevity. Lastly, the cost and availability of the steel angle should also be taken into consideration. It is important to choose a size that is readily available in the market and within the budget constraints. Comparing prices and availability from different suppliers can help in making an informed decision without compromising on quality and performance. In conclusion, factors such as load-bearing capacity, structural stability, dimensions and shape, material properties, and cost/availability should all be carefully considered when choosing the appropriate steel angle size. By evaluating these factors, one can make a well-informed decision that meets the specific requirements of the application.

- Q: Can steel angles be used for door frames?

- Yes, steel angles can be used for door frames. Steel angles provide strength and stability, making them a suitable choice for supporting and reinforcing door frames.

- Q: How do you calculate the moment of resistance for a steel angle?

- To calculate the moment of resistance for a steel angle, you need to consider the properties of the angle section and its dimensions. The moment of resistance is a measure of the ability of the angle to resist bending. The formula to calculate the moment of resistance is: Moment of Resistance = Plastic Section Modulus × Yield Strength of Steel The plastic section modulus can be determined using the following formula: Plastic Section Modulus = (Width × Thickness^2) / 6 In this formula, the width refers to the distance between the outer edges of the angle, and the thickness refers to the thickness of the angle section. The yield strength of the steel is a material property and can be obtained from its specification or reference material. It represents the maximum stress the steel can withstand without permanent deformation. By substituting the values of the plastic section modulus and the yield strength of the steel into the formula for the moment of resistance, you can calculate the value. It is important to note that the dimensions used in the calculations should be in consistent units, such as millimeters or inches, depending on the units used in the yield strength value. This calculation provides an estimate of the moment of resistance for a steel angle and is useful in structural engineering applications to determine the capacity of the angle section under bending loads.

- Q: Can steel angles be used for overhead support in industrial settings?

- Indeed, in industrial settings, steel angles have the capability to be utilized for overhead support. As a structural component, steel angles possess both versatility and strength, rendering them suitable for a multitude of overhead applications. Due to their capacity to bear substantial loads and endure significant stress, steel angles are frequently employed within the construction industry. Frameworks, trusses, and supports for overhead conveyors, cranes, piping systems, and additional industrial equipment are commonly constructed using steel angles. Their exceptional durability, resistance to corrosion, and ease of welding or bolting make them an optimal selection for supplying overhead support in industrial environments.

- Q: Can steel angles be used for fencing?

- Yes, steel angles can be used for fencing. Steel angles provide strength and durability, making them suitable for fencing applications. They can be used as posts or support structures for chain link, wire mesh, or other types of fencing materials.

- Q: Can steel angles be used in the construction of pipe racks?

- Indeed, the utilization of steel angles is applicable in the construction of pipe racks. Steel angles play a vital role in furnishing the necessary structural support and stability required for pipe racks, thereby rendering them an ideal choice for this particular type of construction. These angles can be employed to fabricate a framework or framework support system for the pipe rack, thereby ensuring its robustness and ability to withstand the weight and pressure exerted by the pipes. Moreover, steel angles possess remarkable durability and resistance to corrosion, which proves crucial in an environment where pipes may be exposed to a variety of elements. In summary, steel angles are an appropriate and commonly utilized material in the construction of pipe racks.

- Q: What is the maximum allowable torsional stress for a steel angle?

- Several factors determine the maximum allowable torsional stress for a steel angle, including the specific grade of steel, the dimensions and shape of the angle, and the intended application. Steel angles are commonly used in structural applications, such as supporting beams and frames, and they are designed to withstand various types of stresses, including torsional stress. Engineers typically consult industry standards and codes, such as the AISC Manual or EN 10056, to determine the maximum allowable torsional stress for a steel angle. These standards provide guidelines and formulas for calculating the maximum allowable torsional stress based on properties like the cross-sectional area, moment of inertia, and modulus of elasticity of the steel angle. It is important to note that the maximum allowable torsional stress is usually expressed as a percentage of the steel's yield strength or ultimate tensile strength. This ensures that the angle can safely endure torsional loads without suffering permanent deformation or failure. In practical applications, engineers and designers carefully analyze specific requirements and loading conditions to determine the appropriate maximum allowable torsional stress for a steel angle. They consider factors such as the magnitude and direction of the applied torque, the angle's orientation, and any additional loads or constraints present. Ultimately, the maximum allowable torsional stress for a steel angle is a critical parameter in ensuring the structural integrity and safety of a design. Proper consideration of the steel's properties, industry standards, and specific application requirements is essential for accurate calculations and the selection of an appropriate steel angle capable of effectively resisting torsional stress.

- Q: What is the standard size of steel angles?

- Steel angles come in a range of sizes that vary depending on the region and industry standards. Generally, they are available in equal and unequal leg lengths, with the equal leg angles typically sized between 20mm and 200mm. The thickness of the angle can also vary, typically falling between 3mm and 20mm. However, it is crucial to understand that these measurements may differ based on the specific application or project requirements. To determine the correct size of steel angles for a particular project, it is recommended to consult industry standards or manufacturers.

- Q: What are the different shapes available for steel angles?

- The different shapes available for steel angles include equal angles, unequal angles, and L-shaped angles.

Send your message to us

S400 Hot rolled stainless steel angle for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100000 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords