HRB400 stainless steel angle for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100000 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

OKorder is offering hrb400 stainless steel angle for construction at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

HRB400 stainless steel angle are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's steel angle are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

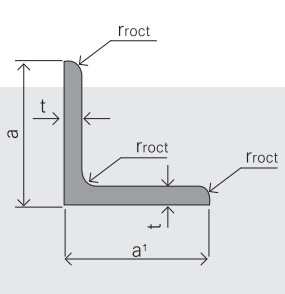

Product Specifications:

1. Invoicing on theoretical weight or actual weight as customer request

2. Length: 6m, 9m, 12m as following table

3. Sizes

4. Payment terms:

1).100% irrevocable L/C at sight.

2).30% T/T prepaid and the balance against the copy of B/L.

3).30% T/T prepaid and the balance against L/C

5.Material details:

Usage & Applications of Angle Steel

According to the needs of different structures, Angle can compose to different force support component, and also can be the connections between components. It is widely used in various building structures and engineering structures such as roof beams, bridges, transmission towers, hoisting machinery and transport machinery, ships, industrial furnaces, reaction tower, container frame and warehouse etc.

Packaging & Delivery of Angle Steel

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

Production flow of Angle Steel

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

FAQ:

Q1: How soon can we receive the product after purchase?

A1: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q2: What makes stainless steel stainless?

A2: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

- Q: How are steel angles priced?

- Several factors typically influence the pricing of steel angles. One of these factors is the current market price of steel, which is influenced by elements such as supply and demand, global economic conditions, and fluctuations in the costs of raw materials. The price of steel angles can also be affected by their size and dimensions, with larger and thicker angles generally costing more. The grade and quality of the steel used in the angle also play a role in determining its price. Steel angles made from higher-grade materials, such as stainless steel or alloy steel, tend to be more expensive due to their superior strength and resistance to corrosion. Furthermore, the quantity of steel angles being purchased can impact the price. Bulk orders or larger quantities often qualify for volume discounts, which can reduce the overall cost per unit. Lastly, the pricing of steel angles may also take into account transportation and logistics costs. Factors such as shipping distances, handling fees, and any additional services required for delivery can all contribute to the final price. In conclusion, the pricing of steel angles is determined by a combination of market conditions, size and dimensions, grade and quality, quantity ordered, and transportation costs. It is important to consider these factors when evaluating and comparing prices from different suppliers.

- Q: Can steel angles be used for handrails?

- Yes, steel angles can be used for handrails. Steel angles are often used as a structural component for handrails due to their strength and durability. They can provide a sturdy and stable support for handrails in various applications.

- Q: What are the different methods of surface finishing for steel angles?

- Some of the different methods of surface finishing for steel angles include painting, galvanizing, powder coating, and abrasive blasting.

- Q: Galvanized steel angles under what conditions?

- Humid environment

- Q: What are the common applications of steel angles in the automotive industry?

- Steel angles are commonly used in the automotive industry for various applications due to their versatility and strength. One common application of steel angles in the automotive industry is in the construction of vehicle frames and chassis. Steel angles are often used to provide structural support and rigidity to the frame, ensuring the overall strength and stability of the vehicle. Another common application of steel angles is in the fabrication of brackets and mounting components. These angles are used to attach various components such as engine mounts, suspension components, and exhaust systems to the vehicle's chassis. Steel angles provide a secure and reliable connection, ensuring the proper functioning and longevity of these components. Steel angles are also utilized in the manufacturing of safety features in automobiles. For instance, they are used in the construction of roll cages, which provide protection to the occupants in case of a rollover or collision. Steel angles are preferred for roll cages due to their high strength and ability to absorb and distribute impact forces, thereby enhancing the safety of the vehicle. Additionally, steel angles find application in the design and production of various automotive accessories and components. They are commonly used as reinforcement in door panels, fenders, and bumpers, improving the overall structural integrity of these parts. Steel angles are also employed in the fabrication of trailer hitches, tow bars, and roof racks, providing a strong and secure attachment point for towing and carrying heavy loads. In summary, steel angles play a crucial role in the automotive industry by providing structural support, facilitating secure connections, enhancing safety, and improving the overall performance and durability of vehicles and their components.

- Q: How do steel angles contribute to the sustainability of a city?

- The sustainability of a city is greatly enhanced by the presence of steel angles, which offer numerous benefits. Firstly, steel angles are essential in the construction industry, as they are utilized in the fabrication of buildings, bridges, and other infrastructure. Steel is renowned for its strength, durability, and ability to withstand external factors like corrosion and fire. With the use of steel angles in construction projects, cities can guarantee the longevity and safety of their structures, thereby reducing the need for frequent maintenance or replacement. This results in a significant reduction in resource consumption over time, thus enhancing the city's sustainability. Moreover, steel angles provide architects and engineers with design flexibility, enabling the creation of innovative and efficient structures. Their versatility allows for the construction of sustainable buildings that incorporate energy-efficient designs, natural lighting, and effective insulation. By incorporating steel angles into the construction process, cities can actively promote sustainable practices and decrease energy consumption, consequently contributing to a more sustainable urban environment. Furthermore, steel is a highly recyclable material, boasting a recycling rate of approximately 90%. By integrating steel angles into construction projects, cities can actively participate in a circular economy by promoting the recycling and reuse of steel products. This practice reduces the demand for raw materials and minimizes waste, thereby lessening the environmental impact of construction projects. The utilization of recycled steel also aids in energy conservation and the reduction of greenhouse gas emissions associated with the production of new steel. In conclusion, the inclusion of steel angles plays a pivotal role in fostering the sustainability of a city. These angles provide durable and long-lasting structures, facilitate energy-efficient designs, and encourage the recycling and reuse of materials. By embracing steel angles in construction projects, cities can establish sustainable infrastructure that positively impacts the environment and the community as a whole.

- Q: How do steel angles perform in corrosive gas or liquid environments?

- Steel angles perform well in corrosive gas or liquid environments, thanks to their high resistance to corrosion. The protective oxide layer that forms on the surface of steel angles helps prevent the steel from being directly exposed to the corrosive elements, ensuring its durability and longevity in such environments.

- Q: What are the different methods of reinforcing steel angles?

- There are several methods of reinforcing steel angles, each with its own advantages and applications. One common method is the use of additional steel plates or brackets. These plates or brackets are typically welded or bolted to the existing steel angle to provide additional support and strength. This method is often used in applications where the steel angle is subject to high loads or stresses. Another method is the use of stiffeners, which are typically smaller steel angles or plates welded perpendicular to the existing angle. These stiffeners help to distribute the load more evenly and prevent the steel angle from buckling or bending under stress. This method is often used in applications where the steel angle is used as a structural member, such as in building frames or bridge supports. Additionally, reinforcing steel angles can be achieved through the use of concrete encasement or composite materials. In this method, the steel angle is embedded within a concrete matrix or combined with other materials such as fiberglass or carbon fiber. This combination provides enhanced strength, durability, and resistance to corrosion. This method is commonly used in construction projects where the steel angle is exposed to harsh environments or requires high performance. Overall, the different methods of reinforcing steel angles provide options for increasing the strength, stability, and durability of these structural components. The choice of method will depend on the specific application, load requirements, and environmental factors.

- Q: What are the different surface coating options for steel angles?

- Some different surface coating options for steel angles include galvanization, powder coating, and painting.

- Q: Can steel angles be used for support frames in industrial machinery?

- Yes, steel angles can be used as support frames in industrial machinery. Steel angles are often chosen for their high strength and durability, making them suitable for providing structural support in heavy-duty applications. They can be easily welded or bolted together to form a sturdy framework that can withstand the weight and forces of industrial machinery.

Send your message to us

HRB400 stainless steel angle for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100000 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords