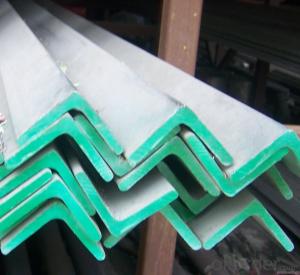

Angle steel for sale with high quality ;

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Specifications of Angle Steel

1. Invoicing on theoretical weight or actual weight as customer request

2. Length: 6m, 9m, 12m as following table

3. Sizes

Sizes: 25mm-250mm | ||

a*t | ||

25*2.5-4.0 | 70*6.0-9.0 | 130*9.0-15 |

30*2.5-6.6 | 75*6.0-9.0 | 140*10-14 |

36*3.0-5.0 | 80*5.0-10 | 150*10-20 |

38*2.3-6.0 | 90*7.0-10 | 160*10-16 |

40*3.0-5.0 | 100*6.0-12 | 175*12-15 |

45*4.0-6.0 | 110*8.0-10 | 180*12-18 |

50*4.0-6.0 | 120*6.0-15 | 200*14-25 |

60*4.0-8.0 | 125*8.0-14 | 250*25 |

5. Payment terms:

1).100% irrevocable L/C at sight.

2).30% T/T prepaid and the balance against the copy of B/L.

3).30% T/T prepaid and the balance against L/C

6.Material details:

Alloy No | Grade | Element (%) | |||||

C | Mn | S | P | Si | |||

Q235 | B | 0.12—0.20 | 0.3—0.7 | ≤0.045 | ≤0.045 | ≤0.3 | |

Alloy No | Grade | Yielding strength point( Mpa) | |||||

Thickness (mm) | |||||||

≤16 | >16--40 | >40--60 | >60--100 | ||||

≥ | |||||||

Q235 | B | 235 | 225 | 215 | 205 | ||

Alloy No | Grade | Tensile strength (Mpa) | Elongation after fracture (%) | ||||

Thickness (mm) | |||||||

≤16 | >16--40 | >40--60 | >60--100 | ||||

≥ | |||||||

Q235 | B | 375--500 | 26 | 25 | 24 | 23 | |

Usage & Applications of Angle Steel

According to the needs of different structures, Angle can compose to different force support component, and also can be the connections between components. It is widely used in various building structures and engineering structures such as roof beams, bridges, transmission towers, hoisting machinery and transport machinery, ships, industrial furnaces, reaction tower, container frame and warehouse etc.

Packaging & Delivery of Angle Steel

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

Production flow of Angle Steel

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

- Q: Are steel angles load-rated?

- Indeed, load-rating is applicable to steel angles. Steel angles serve as structural components widely employed in construction and engineering endeavors. They possess the ability to endure diverse forms of loads, encompassing axial, bending, and shear loads. The load rating of a steel angle pertains to its utmost capacity to sustain a designated load quantity without experiencing any form of failure. Thorough testing and analysis are conducted to ascertain the load ratings for steel angles, taking into account variables such as material properties, geometry, and design criteria. Typically, manufacturers furnish load ratings, which engineers utilize to guarantee the structural soundness and security of a project.

- Q: What is the cost of a steel angle?

- The cost of a steel angle can vary depending on various factors such as size, thickness, and market conditions. It is best to check with local suppliers or online retailers to get an accurate and up-to-date price for a specific steel angle.

- Q: What are the standard dimensions for unequal leg steel angles?

- The standard dimensions of unequal leg steel angles can vary depending on project-specific requirements or the country of use. However, there are widely accepted standard dimensions that are commonly employed across industries. In the United States, the American Society for Testing and Materials (ASTM) typically defines the standard dimensions for unequal leg steel angles. According to ASTM A6/A6M, the standard specification for general requirements for rolled structural steel bars, plates, shapes, and sheet piling, unequal leg steel angles are identified by their nominal size and weight per foot. For instance, a frequently utilized unequal leg steel angle may have a nominal size of 2 x 1-1/2 inches and a weight per foot of 2.71 pounds. Another commonly encountered dimension is 3 x 2 inches, with a weight per foot of 4.23 pounds. While specific project requirements may cause these dimensions to vary, they serve as a general reference for the standard dimensions of unequal leg steel angles.

- Q: Can steel angles be painted or finished for decorative purposes?

- Yes, steel angles can be painted or finished for decorative purposes. Painting or finishing steel angles can enhance their appearance, provide protection against corrosion, and allow for customization to suit specific decorative needs.

- Q: What are the tolerance specifications for steel angles?

- The tolerance specifications for steel angles vary depending on the specific standards and requirements set by the industry or application. These specifications typically include tolerances for dimensions such as length, width, and thickness, as well as tolerances for straightness, squareness, and surface finish. It is important to refer to the relevant standards or consult with manufacturers to determine the exact tolerance specifications for steel angles in a particular context.

- Q: Are steel angles available in non-standard dimensions?

- Steel angles in non-standard dimensions can be obtained. Although standard steel angles are typically manufactured in specific sizes, such as 2x2 inches or 3x3 inches, there are manufacturers and suppliers capable of producing steel angles in custom sizes to fulfill specific project requirements. These custom sizes may involve varying leg lengths, thicknesses, or overall dimensions that are not commonly found in standard steel angles. Achieving the desired dimensions can be accomplished through processes like cutting, bending, and welding when fabricating custom steel angles. Nevertheless, it is important to consider that non-standard dimensions may result in additional time and cost for production compared to readily available standard sizes.

- Q: What is the typical thickness of a steel angle?

- The specific application and the desired strength are factors that can cause the typical thickness of a steel angle to vary. Generally, steel angles are offered in various thickness options, ranging from 1/8 inch (3.18 mm) to 3/4 inch (19.05 mm) or greater. Determining the appropriate thickness involves considering aspects like load-bearing necessities, structural design, and the desired durability level.

- Q: What is the typical density of steel angles?

- The typical density of steel angles can vary depending on the specific type and grade of steel being used. However, on average, the density of steel angles ranges between 7.7 to 8.1 grams per cubic centimeter (g/cm³) or 7700 to 8100 kilograms per cubic meter (kg/m³). This density is relatively high compared to other materials, making steel angles strong and durable for various structural and construction applications.

- Q: How do you prevent steel angles from bending under load?

- In order to prevent steel angles from bending under load, several important measures can be taken: 1. Choose the appropriate size and material for the angle: It is important to select a steel angle that is of sufficient size and material strength to withstand the expected load. Seeking guidance from structural engineering guidelines or professionals can help determine the correct dimensions and material composition for the specific application. 2. Strengthen the angle: Enhance the strength of the steel angle by adding additional support or reinforcement. This can be achieved through techniques such as welding extra plates to the angle, utilizing gussets or stiffeners, or incorporating diagonal bracing. These reinforcements help distribute the load more evenly and reduce the likelihood of bending. 3. Increase the thickness: If possible, increasing the thickness of the steel angle can improve its ability to bear loads. A thicker angle will have greater resistance to bending and deformation under load. 4. Ensure proper installation: It is crucial to install the steel angles correctly and securely in order to maximize their resistance to bending. This involves using appropriate fasteners, such as bolts or welds, and following proper installation techniques. 5. Avoid excessive loads: Preventing steel angles from bending under load also requires careful consideration of the maximum load they will encounter. It is important to avoid overloading the angles beyond their design capacity, as this significantly increases the risk of bending or failure. 6. Regular inspections: Regularly inspect the steel angles for any signs of bending, cracking, or deformation. Prompt identification of potential issues allows for timely maintenance or reinforcement, preventing further damage or accidents. To ensure the proper design and implementation of these measures, it is crucial to consult with a qualified structural engineer or professional experienced in steel fabrication.

- Q: What is angle iron?

- Angle called angle, the steel strip is perpendicular to each other on both sides into the corner.

Send your message to us

Angle steel for sale with high quality ;

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords